Written and photographed by

John M. Young

Well my interest in late 1940s pipes has yet to subside. Although there are a couple of samples that are just beyond this retired teacher’s means. I came across an advertisement for a very interesting pipe called a Roto Bowl. Here is the ad from 1947 vol. 4 Pipe Lovers Magazine

(Pipe Lovers Magazine 1947 all numbers : Free Download, Borrow, and Streaming : Internet Archive p. 99) How does it work? I just want one to take apart and see what the parts are like and what they are meant to do. Okay, I want to restore it too. Then, I’ll probably lose interest and not call her back. Oh wait, we are talking pipes. Well due to the wonders of the Internet I found one. Yes, on eBay. And, it only has a starting buy-out price of (dramatic pause) US $812.50 or Best Offer. No, seriously. Here is the link – Francis Ellsworth Roto Bowl Pipe 1946 Briarwood Tobacco Pipe RARE UNSMOKED! | eBay. Although if you are reading this in the future, the link may be gone. Here’s the screenshot too.

What does this have to do with our gnarly little darling, the LHS Purex? Umm, I don’t know, I was just trying to write an introduction and I guess I got carried away. Oh yeah, now I remember, I was talking about my current crush on late 1940s pipes. And how Sterncrest (LHS) has like ¼ page ads in every volume of Pipe Lovers Magazine. Remember the LHS London Royal restoration? Okay, it was over a month ago but, here’s the link.

If you are like me and have forgotten about LHS (Ludwig and Hugo Stern) and their pipe making, I’ll try to give a quick review.

“Ludwig Stern, a successful pipe manufacturer since 1893 and closing around 1960, reorganized his company along with his brother Hugo Stern, opening a factory in 1911. They named the company L&H Stern Smoking Pipes & Holders. The newly formed company was moved into a six story building on the corner of Pearl and Waters street Brooklyn, NY.

Thoroughly organized in all departments, and housed in a well-lighted and ventilated modern office and manufacturing building, the firm of L&H Stern Inc. is located near the first arch of the Manhattan bridge, near the river and convenient to the Brooklyn bridge, which makes it accessible from all the hotels in the metropolis for visiting buyers. The structure is six stories with a seventeen-foot basement, with light on three sides through prismatic glass windows, the first floor being seven feet above the sidewalk. Light enters the upper floors from all four sides.

L&H Stern is known to every important wholesaler and jobber in the country. LHS manufactures a complete line of briar pipes. Ginmetto wood pipes are also made, as well as Redmanol goods, the man-made amber. The first substitute for amber. Everything, even down to the sterling silver and other metal trimmings are made under one roof.” (LHS – Pipedia)

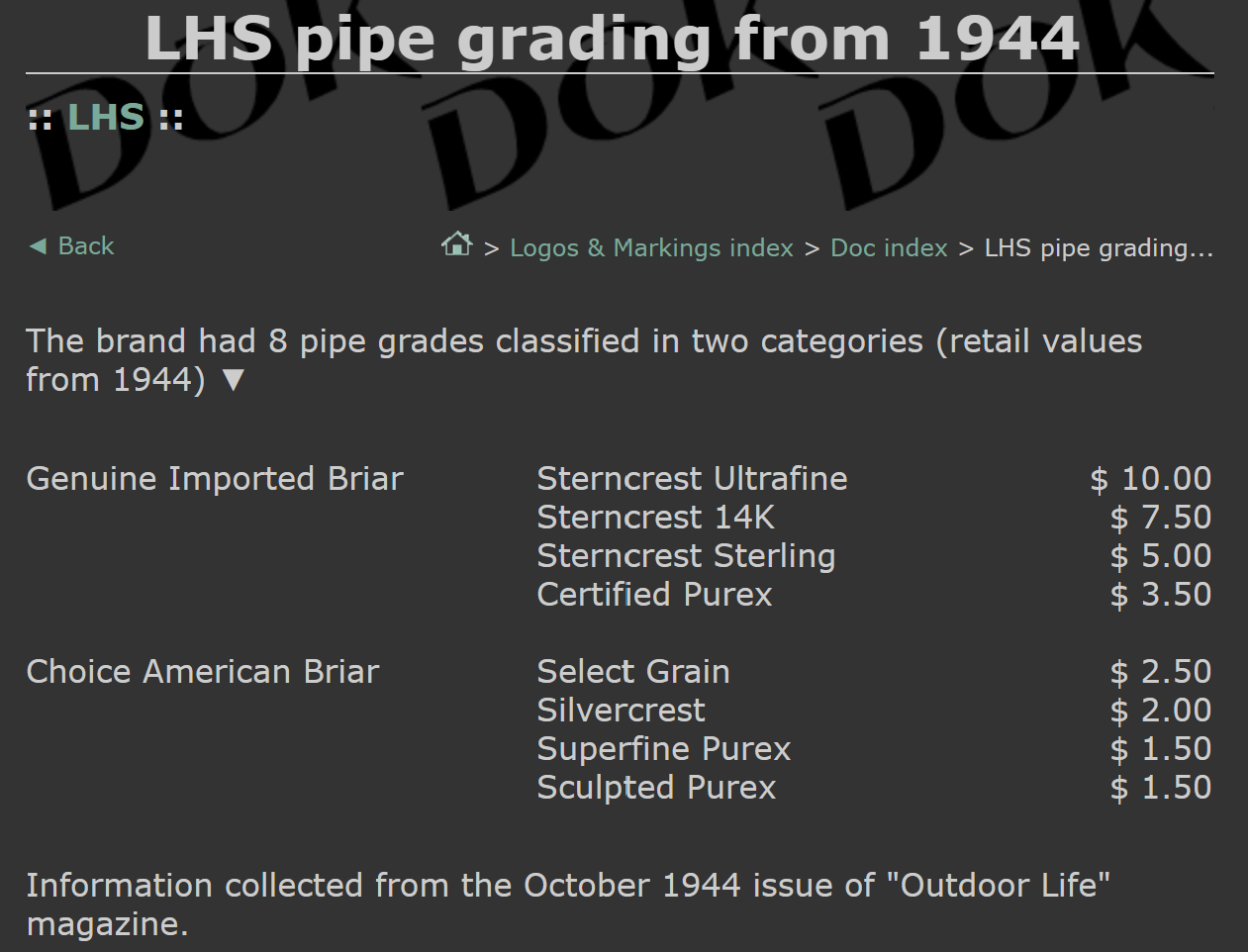

So, here we have an old company that made a lot of different pipes. Here is the list of brands or lines from 1944.

(Document: LHS Grading — Pipes : Logos & Markings – (pipephil.eu))

There is our little darling at the bottom of this list. She is kind of a cheap little pipe but I refuse to let that stand in the way of a good relationship. Although I remember talking to a buddy about a girl he met at a bar. He said, “She’s fun and I like her, but I wouldn’t bring her home to meet mom” (personal conversation). Although my mother probably would have found this little darling cute.

Let’s see if we can narrow down the manufacture date a bit more.

“Some models were made before, during, and after WWII. LHS was one of the main pipe supplier for US soldiers during WWII.

Pre-war pipes were stamped Real Briar Root, or Briar Root. Some war time pipes were made from domestic briar, or “American” briar and were void of any briar stampings. Many American pipe makers lost their over seas supply of Mediterranean briar shortly before and during the war. Post war pipes were stamped Imported Briar to assure customers that they were buying premium briar once again.” (LHS – Pipedia)

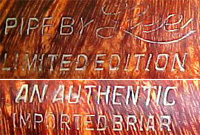

So there we have it. This cute LHS Sculpted Purex does indeed have a stamp “IMPORTED BRIAR” on the bottom of the shank. No, not a little trashttoo (tattoo on the small of her back).

That little beauty places this pipe as a post WWII-1960 manufactured pipe. and matches the piphil.eu data file for stamps.

(LHS — Pipes : Logos & Markings (pipephil.eu))

This LHS Sculpted Purex was one of a 3 pipe lot won from eBay. The other 2 are also late 1940s that will make future blog posts. Upon arrival she looked great except for one massive flaw. I’ll let you see if you can find it from the “before” photos.

You are getting warmer.

Still warmer.

Getting warmer.

I know, you are feeling like a kid in the back seat going on vacation; “are we there yet?”

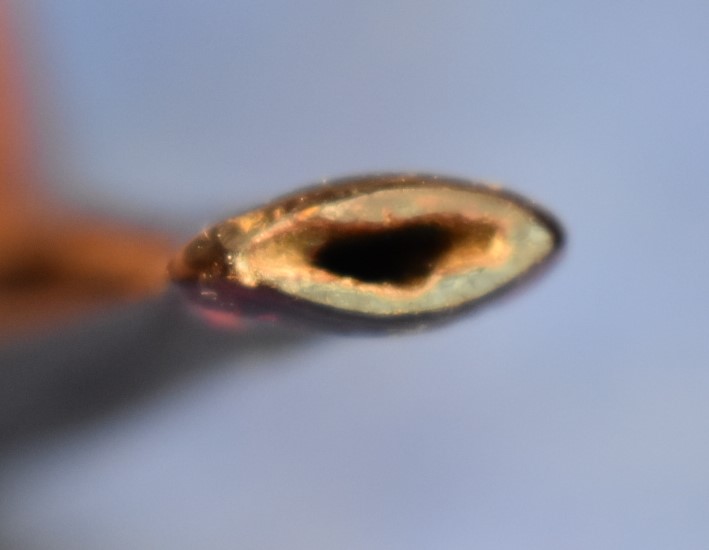

Aaaughhh! That’s awful. Don’t look, children, you’ll have nightmares.

Don’t worry, I’ll show you how I fix those. Seriously though, she was in good shape save for that hole in the stem. I used to fear working on those, now I like to. The biggest potential problem that I saw, other than the hole, was the fact that this pipe had been used a lot. For a hole like that to be chewed through the mouthpiece, it had to be in someone’s mouth a great deal. That indicated that the airway cleaning might be difficult. And, did you see the matching aluminum edged red circles on both the shank and the stem? That was a very nice touch for a “cheap” pipe.

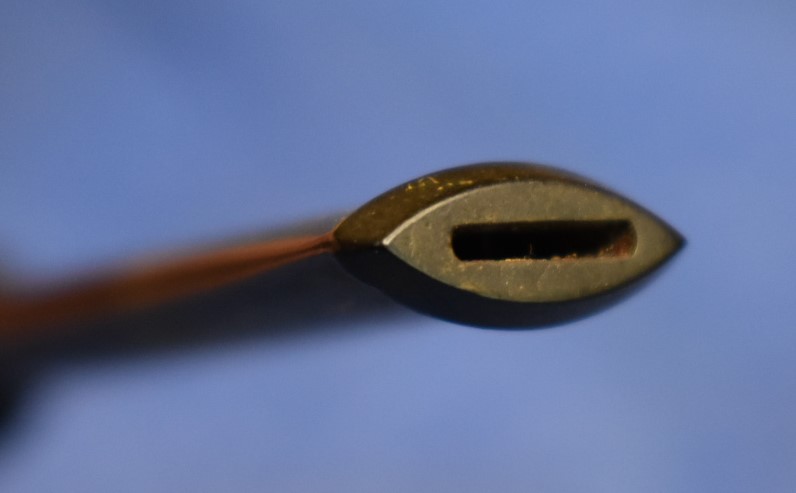

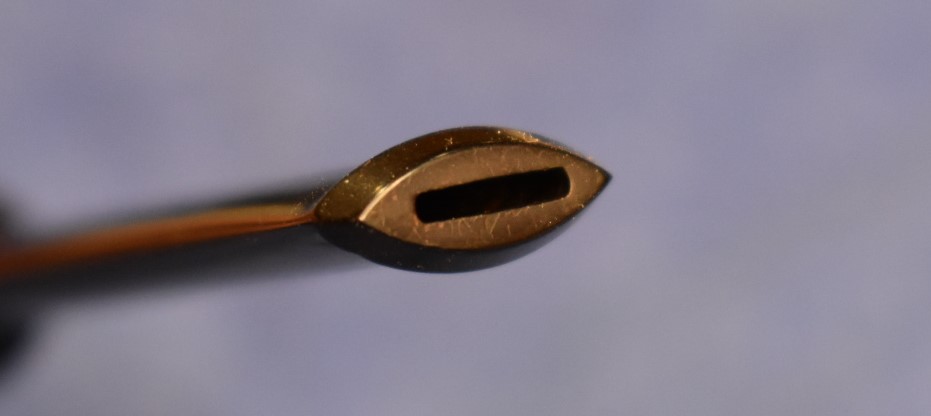

The first step with this restoration is to have a clean piece of denim placed on the workbench and disassemble this Purex. The aluminum stinger is a two piece, one of which went into the 99% isopropyl alcohol for a soak.

Step two, reaming the tobacco chamber. The chamber is too narrow for the remaining blades of my PipNet so, the Scottie Reaming tool, Smokingpipes Low Country knife and the General triangular scraper were put to use The chamber was then sanded with 220 sandpaper wrapped around a wood dowel. This was another case of soft Algerian briar that literally sloughed off the cake. I do love a good old Algerian briar. The cake had completely protected the chamber interior.

Next came the shank cleaning. Surprise, it was pre-cleaned for my convenience. Either that or the previous keeper was a good and proper pipe cleaner. Thank you. The cotton swabs did come back a bit discolored as their isopropyl alcohol dissolved the tars within the airway. However, they soon were coming back clean.

The stummel was then taken to the sink for the Murphy’s Oil Soap scrubbing. The Murphy’s was used undiluted and scrubbed once with a medium bristle toothbrush then rinsed with warm water and dried with a cotton dish towel. The stummel was then scrubbed a second time with undiluted Murphy’s and a brass wire bore brush. Since the rustication was so deep and rugged I used the wire brush as well. This too was rinsed with warm water and dried again with the now slightly damp cotton dish towel. The stummel was then returned to the workbench where alcohol was poured into the bowl and allowed to slosh around and poured out through the airway. You can see a very slight coloring of the alcohol in the medicine cup. The stummel was also wiped with an alcohol wetted make-up pad. This too slightly discolored the pad.

I then wetted another make-up pad with acetone and vigorously wiped the stummel. I removed more finish from the stummel.

Next the stem was going to be cleaned using bristle pipe cleaners dipped in 99% isopropyl alcohol. It was quickly discovered that the stem was softened and began to dissolve with the alcohol. As the alcohol evaporated the stem lost the sticky feel. I decided that it should be cleaned with soap and water. I used Dawn dish soap and hot water with bristle pipe cleaner to clean the airway. Both parts of the stinger were also cleaned using alcohol and pipe cleaners along with a cotton rag and cotton swabs. THe aluminum was then polished with a 4000 micro-mesh pad.

It was time to address that scary hole in the bottom of the stem. It kind of looks like it goes through the top and bottom in these photos. That is an illusion, it was only in the bottom. I first filed the area from the button shank-ward for about 1 cm. This would allow the black cyanoacrylate (CA, super glue) a nice rough surface to adhere to.

I frequently will cut a piece from a plastic lid material into a custom fit insert and press this insert into the airway. The insert acts as a dam for the CA and keeps it from out. I used a slightly different method enlisting a pipe cleaner and scotch tape. I folded a soft pipe cleaner in half and wrapped the folded end with scotch tape. There seem to be two main types of scotch tape – the good stuff (3-M brand flat/matte) and the cheap stuff (no-name clear). They each have their uses. I like the good stuff for wrapping the pipe cleaner as the CA does not adhere to it at all.

The good stuff wrapped pipe cleaner needs to be a tight fit into the airway. You want as little CA as possible to enter the airway on the scotch tape. The hole then gets a drop of black CA applied to it. This CA is quickly sprayed with a cyanoacrylate drying accelerator.

The key to using the accelerator is numerous thin coats or small drops of CA. The accelerator comes into contact with the liquid CA and starts the curing process as it quickly evaporates. If the drop is too thick the accelerator cannot reach the bottom and it remains liquid. I used 2 applications to fill the hole. Another warning is not to remove the inserted dam too soon. Since the CA is very thin at this point removing it can cause it to break through and reopen the hole. After the initial hole was filled I started expanding the CA covered area. This makes blending the black CA to the existing stem less noticeable.

After the coat of CA was applied, I again spritzed with the accelerator and allowed the accelerator to evaporate. Another warning: Some stem materials are affected by the accelerator and it causes it to soften. This usually will return to normal after the accelerator dries. Until it does the stem can be soft and if touched you can leave fingerprints in the stem surface causing you extra sanding and micro-meshing to mitigate. Also, notice the Exacto knife blade in the photo. For a few seconds after the accelerator is applied the CA will be soft. This time can be used to cut the back side of the button straight. This reduces the amount of time spent filing and sanding the button edge.

In the above photo, you can see two slivers of CA that were cut from the back side of the button while the CA was still soft. After the CA cured or dried (I’m not sure of the correct term) I filed the surface flat using a flat needle file. Additional CA was applied to fill low spots and was again spritzed with the accelerator.

Once cured/dried I again filed. This time there are no low spots and I was able to file the high spots flat. Apologies for the photo focus. These were taken with the phone, not the NIkon.

Once filed flat the CA was fine filed with an emery board. A flat sander works better that a finger as it allows for even sanding rather than curving like my finger would.

I removed the dam (good stuff wrapped pipe cleaner) and inspected for CA overflow in the airway. I could see none. Now the fine sanding using the sanding sponges could proceed. I used the 1000-3500 sanding sponges with a paper towel wetted with mineral oil to wipe between each sponge. Yeah, the Captain Pete made a couple of photo-bomb appearances here. I left the below two photos uncropped a bit to show where I had been wiping the sanding dust from the sponges on the denim work surface. Keeping the sponges clean helps the sanding process.

Now for a slightly interactive blog session. Remember the hole was on the bottom of the stem. Which photo is of the repaired hole, top or bottom? Don’t worry this is not being graded.

There you have it, how I repair and rebuild stems. The CA can be purchased in many different colors. Although, I was internet shopping the other day and I was shocked at the inflationary price increases for CA.

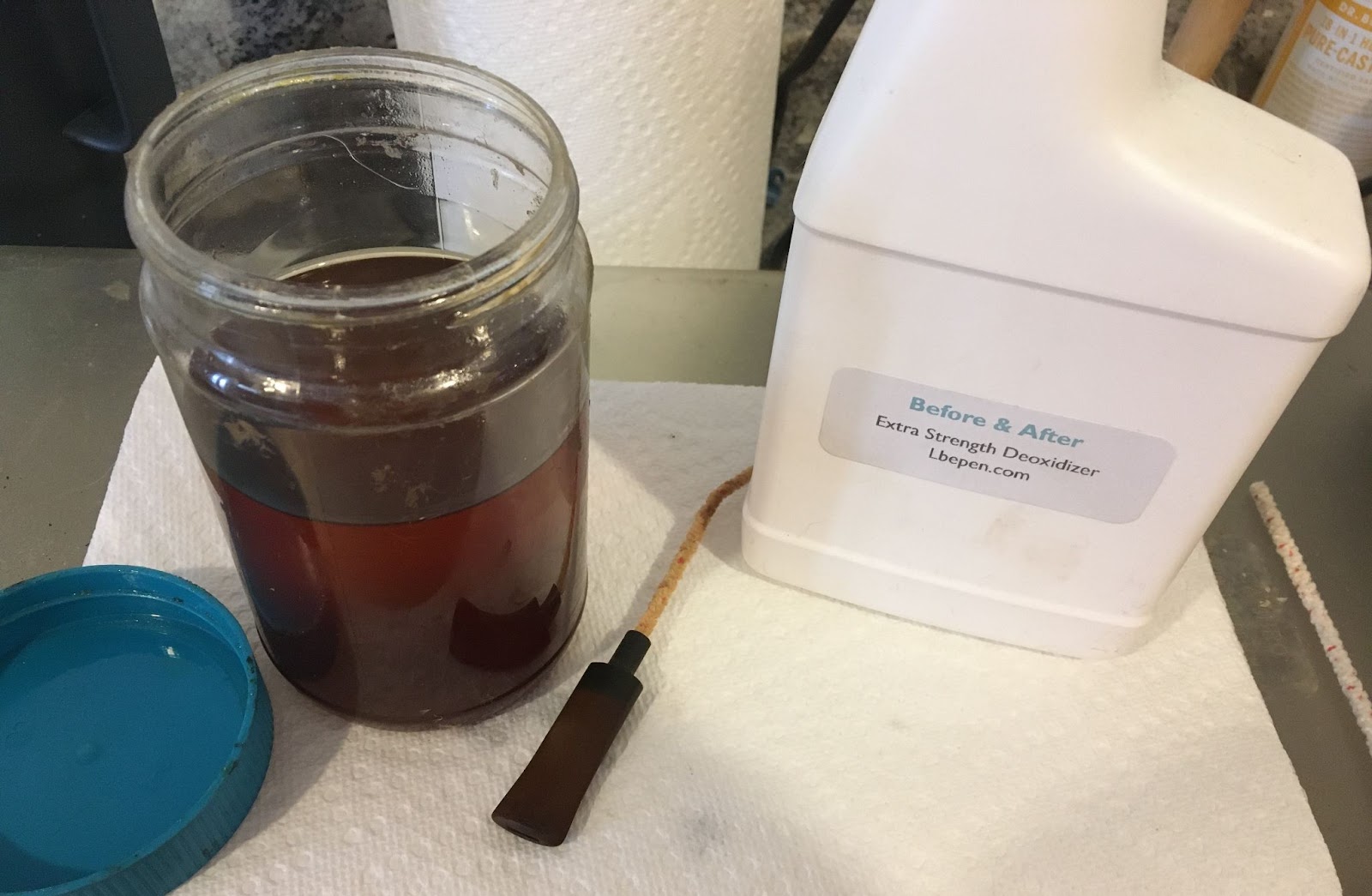

The micro-meshing of the stem proceeded from micro-mesh pad 4000-12000. Between each pad I applied a small drop of Obsidian Oil, rubbed it in with my finger and wiped it with a paper towel. After the micro-meshing I used both the Before and After Fine and Extra Fine polishes. These were applied with a finger and hand rubbed using a soft cotton rag.

With the stem completed I was ready for the arduous task of sanding the stummel. Oh year, I was completely out of arduous. Good thing none was needed. The rustication or “sculptured” texture of the stummel required nearly no work. I lightly sanded it with a 3200 micro-mesh pad to give it a bit more of a contrast look by removing stained briar from the high points of the rustication. I liked the lighter browns peeking through as highlights. The stummel was then treated with Before and After Restoration Balm. I used a baby toothbrush to work the balm into all the nooks and crannies. This was allowed to sit for about 30 minutes.

After 30 minutes, I wiped away the remaining Restoration Balm with the inside of an athletic sock, using the thick terry cloth to get into the above-mentioned nooks and crannies.

The above crummy photo is meant to show the cleaning of the baby toothbrush by dipping it into isopropyl alcohol and rubbing it on the denim work surface a few times. I wanted to use the brush for the waxing and did not want Restoration Balm in my wax.

I again used the baby toothbrush as the applicator, this time for Decatur Pipe Shield No-Buff Wax. I’ve had good results with this wax on heavily rusticated pipes. The wax was allowed to dry for 20 minutes and was then bushed using a shoe shine brush followed by hand buffing with a soft cotton cloth.

Overall this was a fun restoration. I did not have to spend a great deal of time working on tar removal. The pipe is relatively dainty with a shank diameter of only ½ inch (12.7 mm), a bowl outside diameter of 1 ⅜ inches (35 mm), bowl height of 1 ¾ inches (44.5 mm) and a respectable length of 5 ¾ inches (146 mm). See, Americans can do the metric system. I think the size is why the pipe is at the bottom of the LHS quality scale. I was quite pleased with how well the old LHS Purex turned out. I have not been using a shape name with this pipe since I am unable to place it on any shape chart from LHS. The bowl has a slightly paneled look from above but that may just be due to the rustication. It does have a forward cant and a slight flaring from the shank to the rim. I guess I’ll call it a Dublin. I do hope that you have found something here useful in your own restorations or were at least slightly entertained. If you enjoy this sort of thing, please click the like and subscribe. I thank you very much for taking time to read the ramblings of an old pipe lover.

Below are some photos of the finished LHS Sculpted Purex Dublin.