Photographed and written by

John M. Young

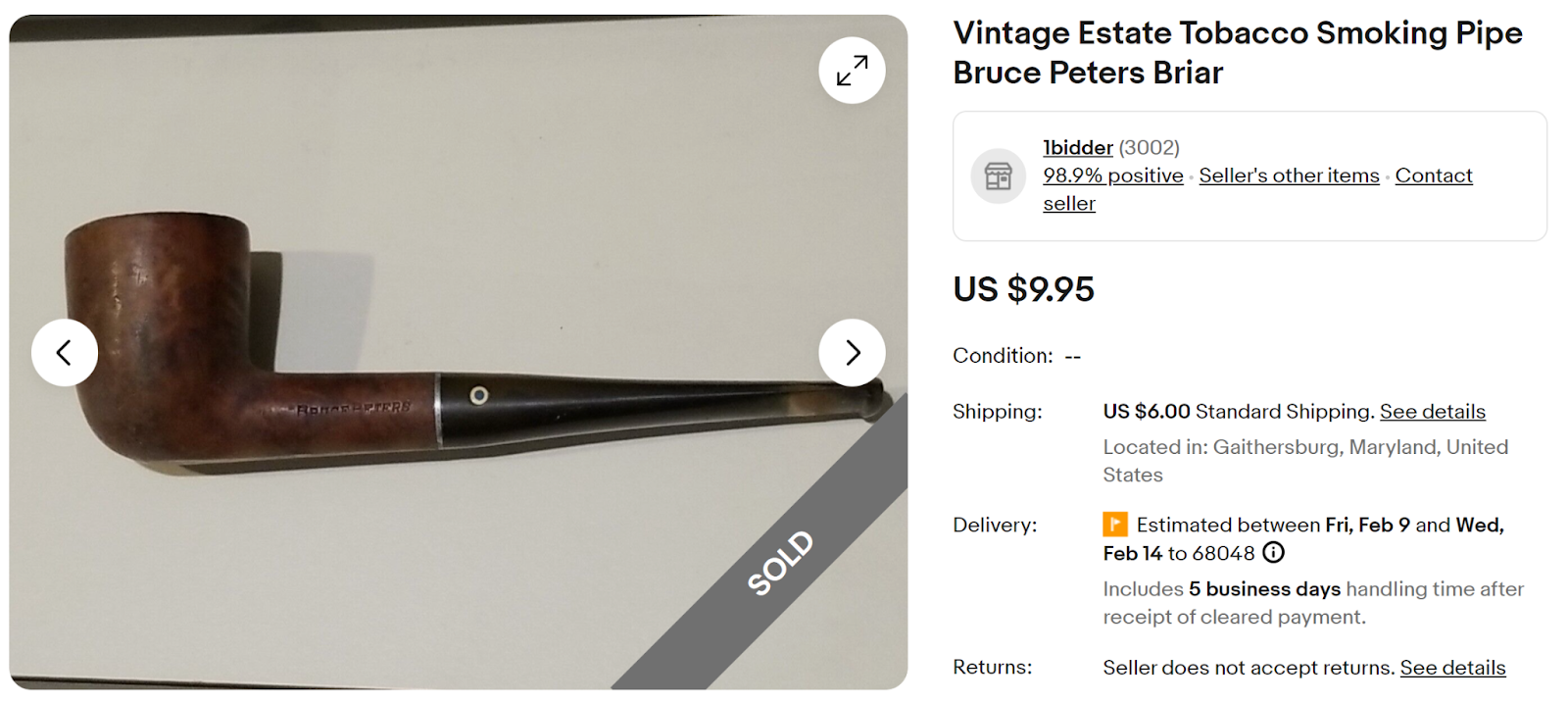

I know what you are thinking: “Dang Young, you must be getting old and didn’t realize that you already posted that restoration.” And I reply: “Hah, this is a different one. This one has a screw-in tenon and a pre-1955 logo.” You are correct though, I am getting old. I came across two more of these Kaywoodie Hand Mades the other day and settled on a price with the seller. This one has a lovely tapered stem while the other one has a saddle stem. These pipes make me think of the word “lumber” when I handle them. They are large. Both over 2.5 ounces (71 g). Not clenchers but, I am sure they will be cool smokers.

I am going to use the historical information from the previous Kaywoodie HandMade restoration. I linked that blog as well, for those who would like to read it.

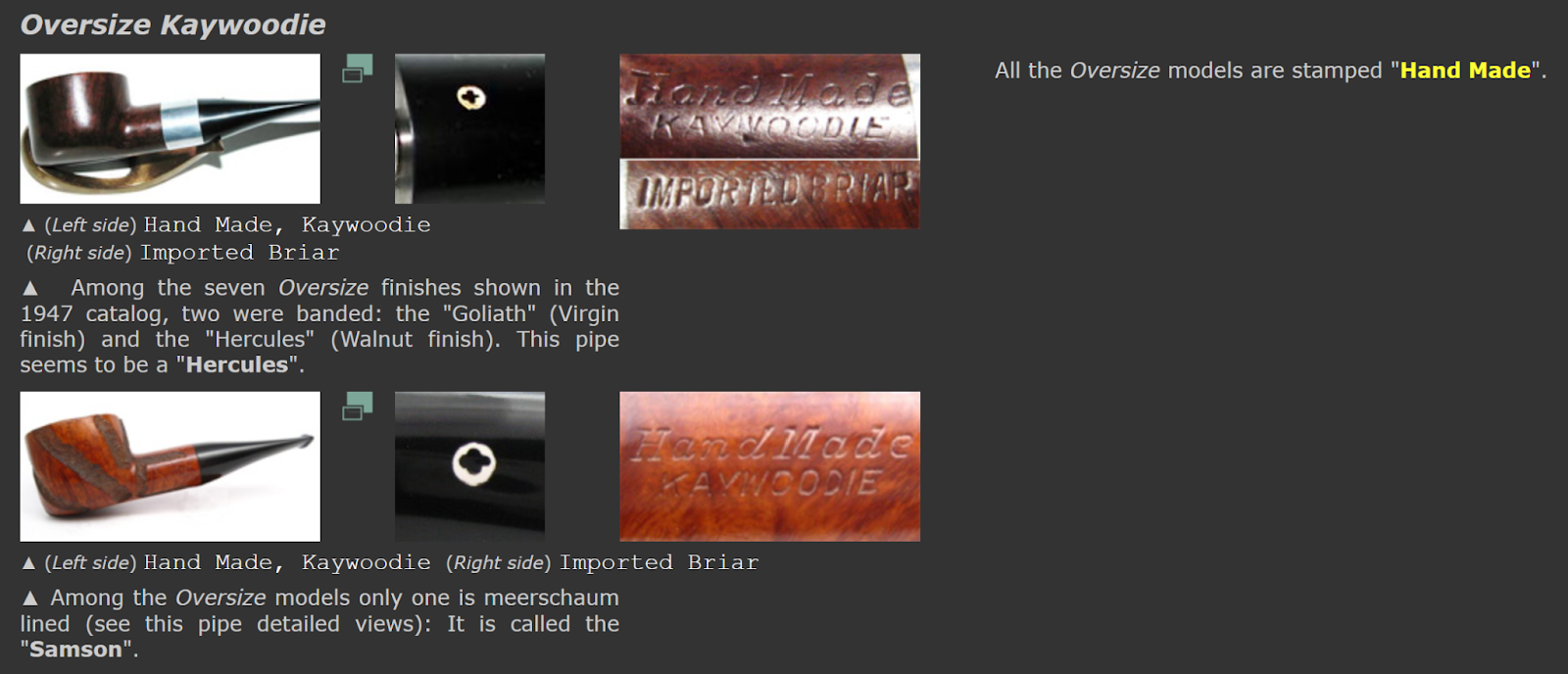

“Kaywoodie name first appearing in February of 1919.” (Kaywoodie History – Greywoodie LLC) The history of Kaywoodie pipes is fortunately well documented thus, allowing rather precise dates for a Kaywoodie collector to declare the provenance of their charges. The above pictured Kaywoodie is stamped HANDMADE over KAYWOODIE (left) and IMPORTED BRIAR (right). No shape number is present.

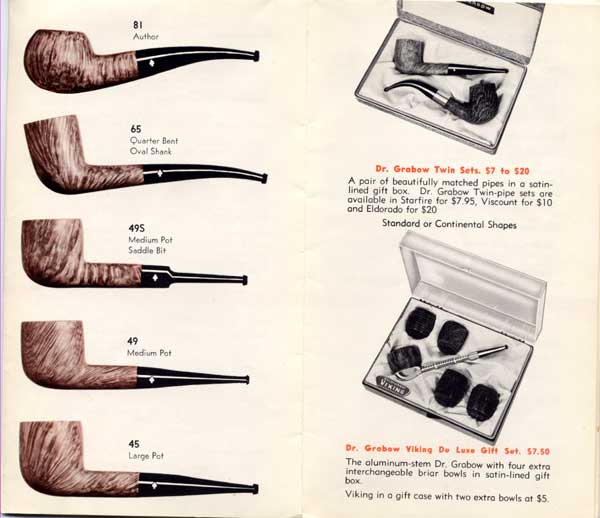

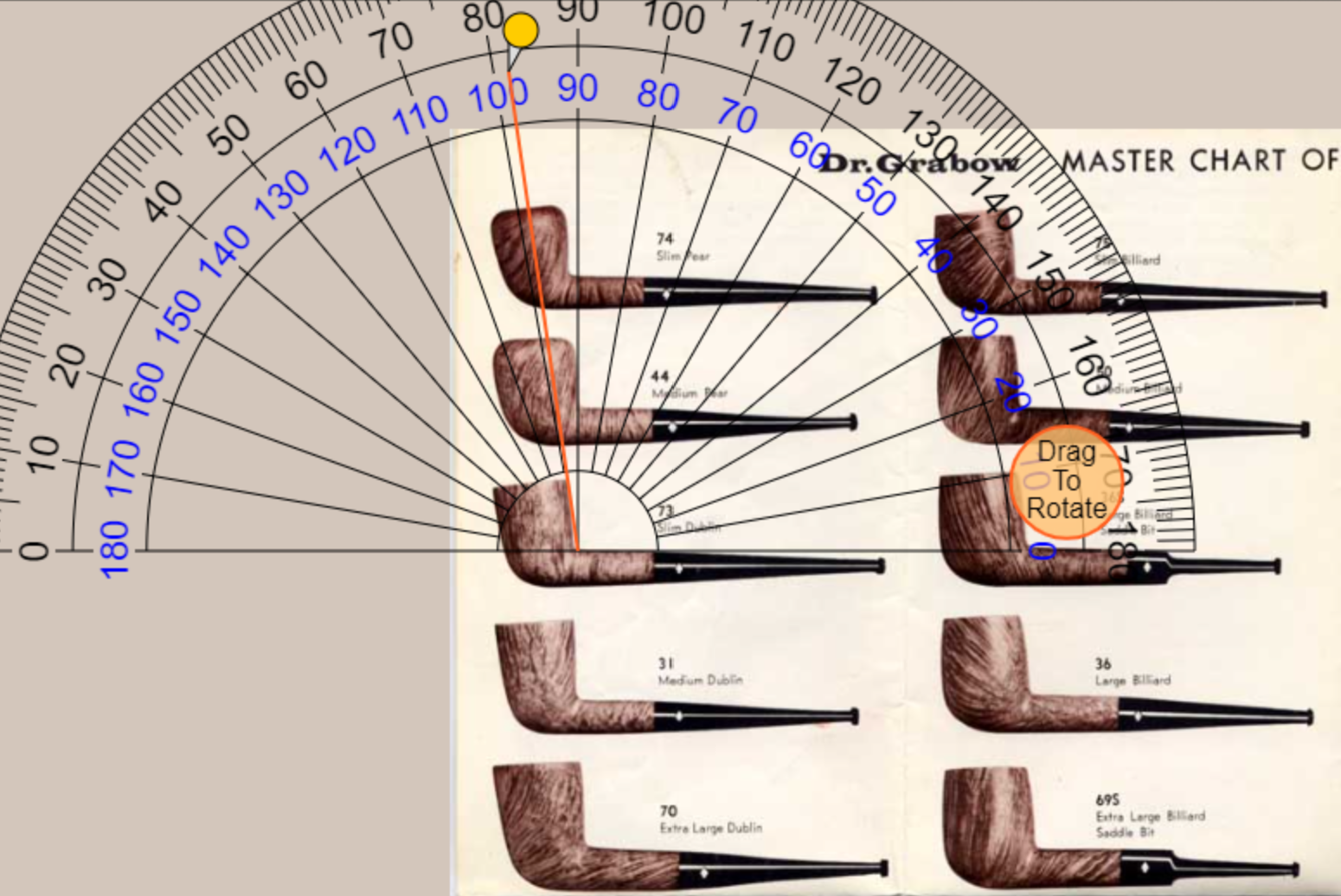

Using this information and referring to the Kaywoodie Collectors’ Guide listed on pipedia.org I found that these pipes were made during the following years:

“Handmade-Oversize-Carved 1947-1955 on and off” (https://pipedia.org/images/3/3d/Kaywoodie_Pipe_Names.pdf) and that

“The Oversize Kaywoodies were, as the name implies, “Giants”. Lowndes notes that these pipes were stamped simply, “Hand-Made”. The pipes were all roughly “bulldogish” in appearance and were available in the following styles and grades7 : • Hand-carved “Colossus” ($10) • Walnut finish, banded “Hercules” ($20) • Hand-carved “John Henry” ($10) • Virgin finish, specimen grain “Paul Bunyan” • ($25)Virgin finish, banded specimen grain “Goliath” • ($25)Walnut finish “Atlas” • ($20)Hand-carved, Meerschaum-Inlaid “Samson” ($15)” (Kaywoodie Collector’s Guide – p10.pdf)

Looking into the stampings, I went to piphil.eu for confirmation. ThereI was able to find an exact match of this pipe’s stampings.

(Kaywoodie series from L to Z — Pipes : Logos & Markings (pipephil.eu))

Well, that was easy. This large Kaywoodie Hand Made, though not very “bulldogish” was most likely made between 1947 and 1955 at the West New York, New Jersey factory. If you would like to see the 1947 Kaywoodie catalog here is a link: Kaywoodie_1947.pdf (pipedia.org). It is a fascinating read with great old marketing photos and illustrations. Just out of curiosity I wondered what $10 in 1947 was equivalent to today. According to a bis.gov inflation calculator it is $131.09 (Using Dec. 1947 and Dec. 2023)(CPI Inflation Calculator (bls.gov)). I highly recommend reading the above links for further Kaywoodie history.

With that perfect example of a generation-X lazy re-use of a previous blog history it is time to get to the restoration. Here is what the Kaywoodie HandMade taper stem (that is what I’m calling it) looked like upon arrival.

This looked like a normal restoration. The main tasks to be completed should be: Reaming the tobacco chamber, cleaning out the airway, cleaning and removing any finish from the stummel, removing the oxidation, and restoration of the stem, wax and polish. It always sounds easier than it actually turns out to be but I am an optimist.

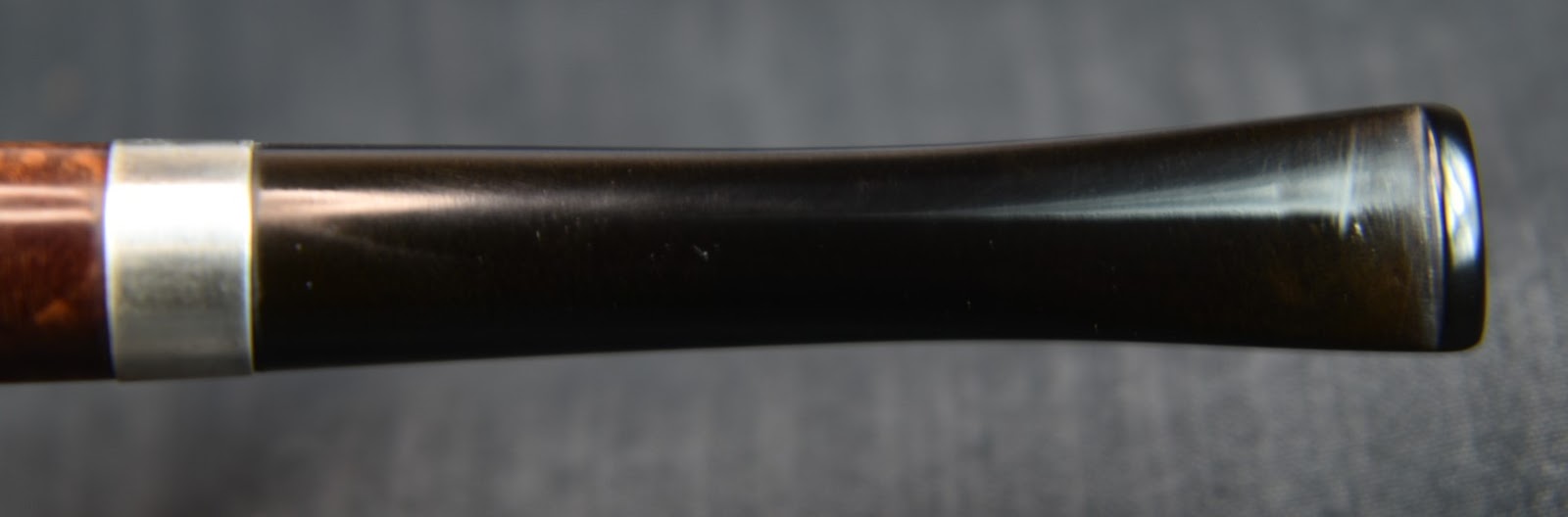

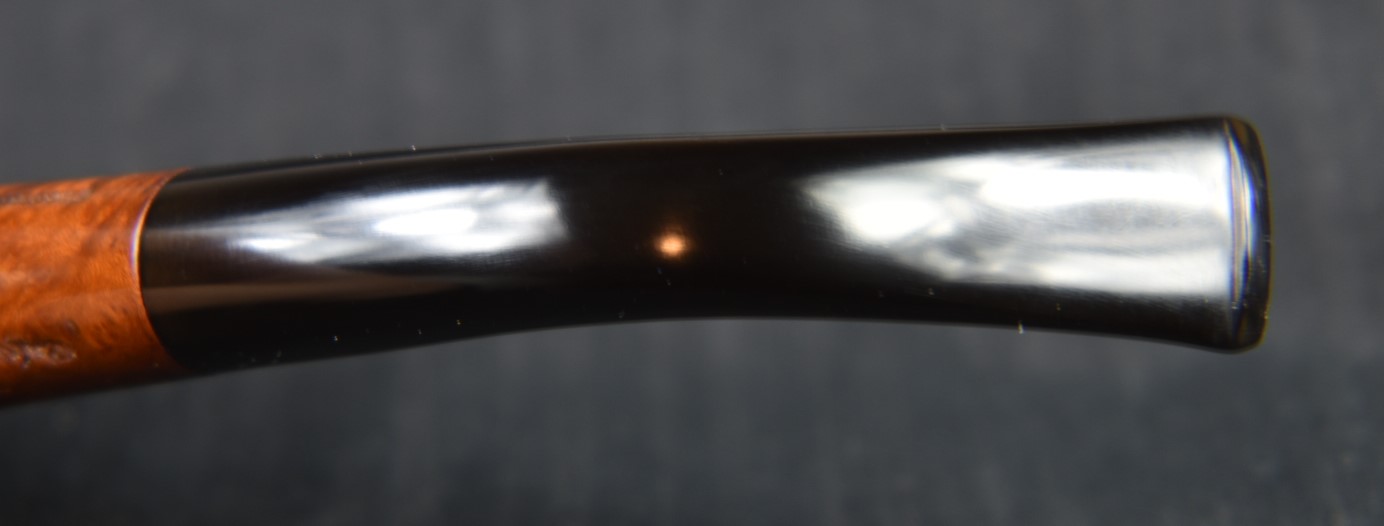

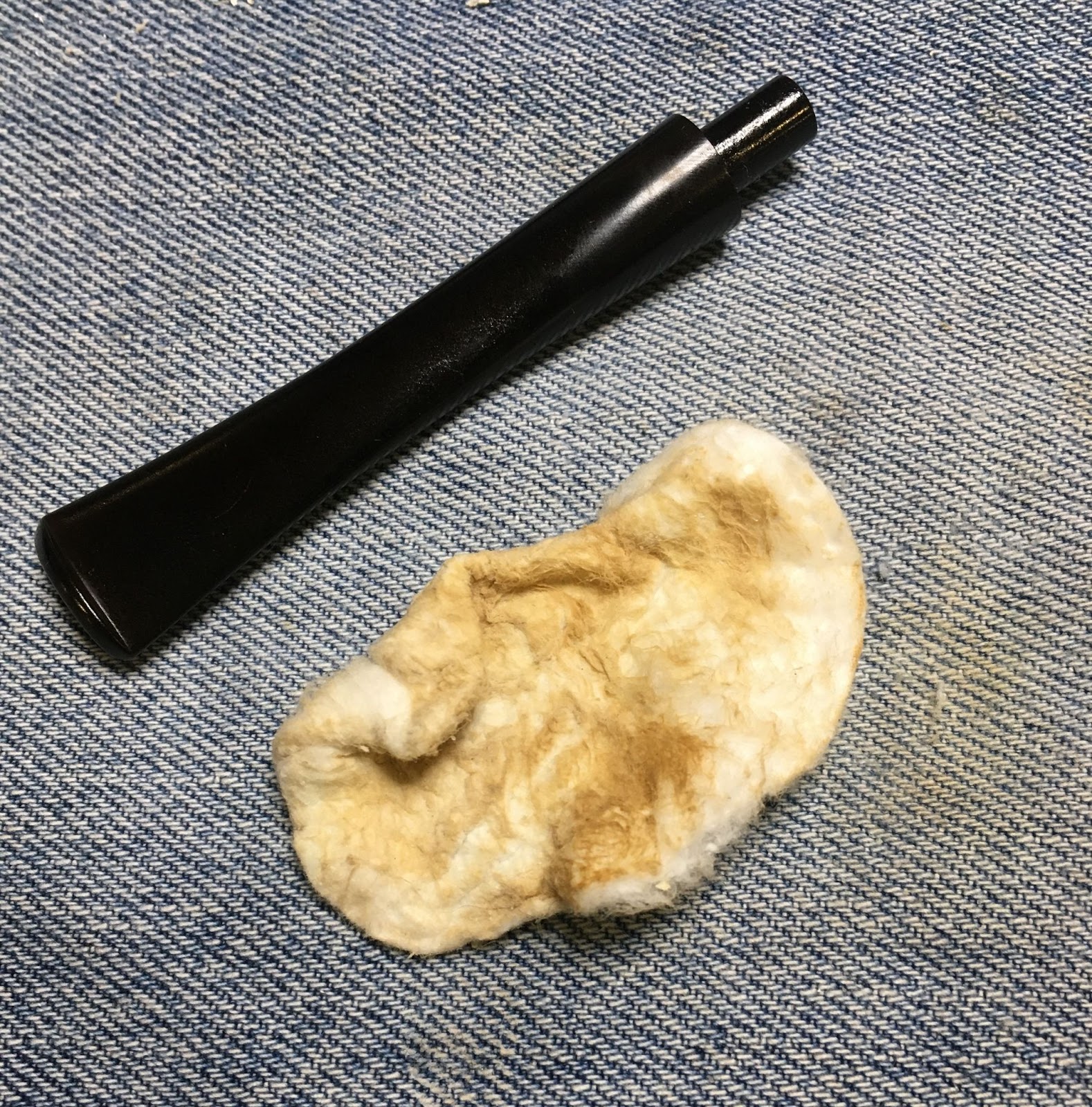

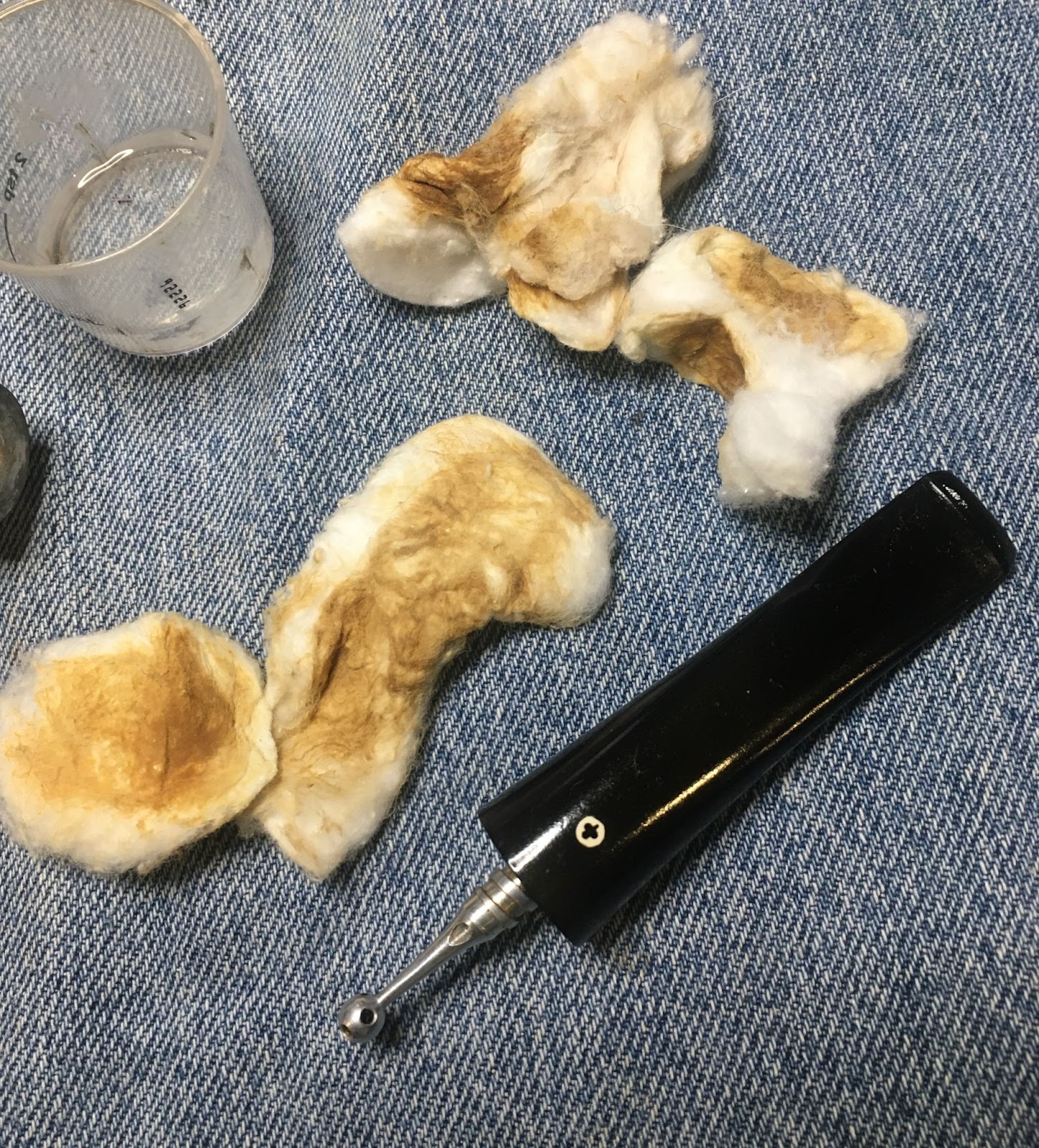

I started with a clean denim piece for the work surface and started working on the stem.

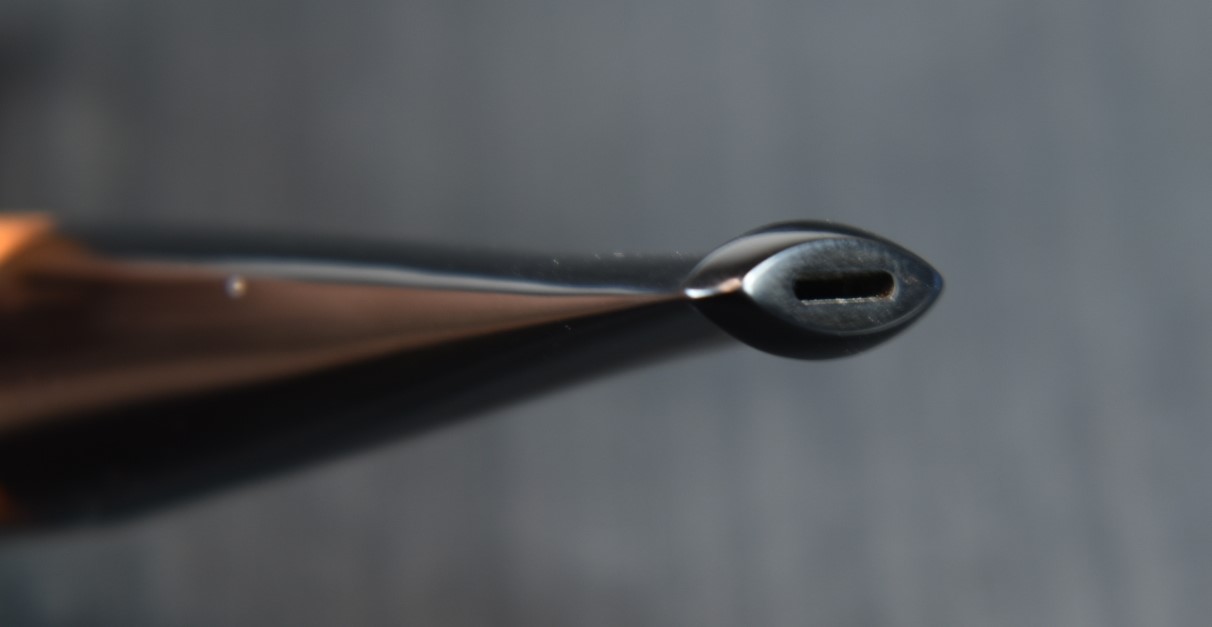

I began with the airway within the stem. I am not a big fan of stingers especially, stingers that don’t come apart. At least with those you can slide out the funky shaped end-piece and run a pipe cleaner through a fairly open hole. Kaywoodies on the other hand, not so much. I was able to get a bristle pipe cleaner dipped in alcohol from the button end down into the stem. Fortunately the stem was not too dirty. Thank you, previous owner. A couple pipe cleaners later and the stem was clean.

Nex, I rubbed the surface with 0000 steel wool then dipped the steel wool into 99% isopropyl alcohol and cleaned up the stinger. After the steel wool I thought that I would not need to give this stem a soak in the Before and After Deoxidizing solution.

The stinger cleaned up nicely and the oxidation on the stem looked like all it needed was Soft Scrub on a make-up pad. Well, several applications of Soft Scrub, that is.

After a mineral oil rub the stem was looking much better. I set it aside to soak-in some oil and started to work on the stummel.

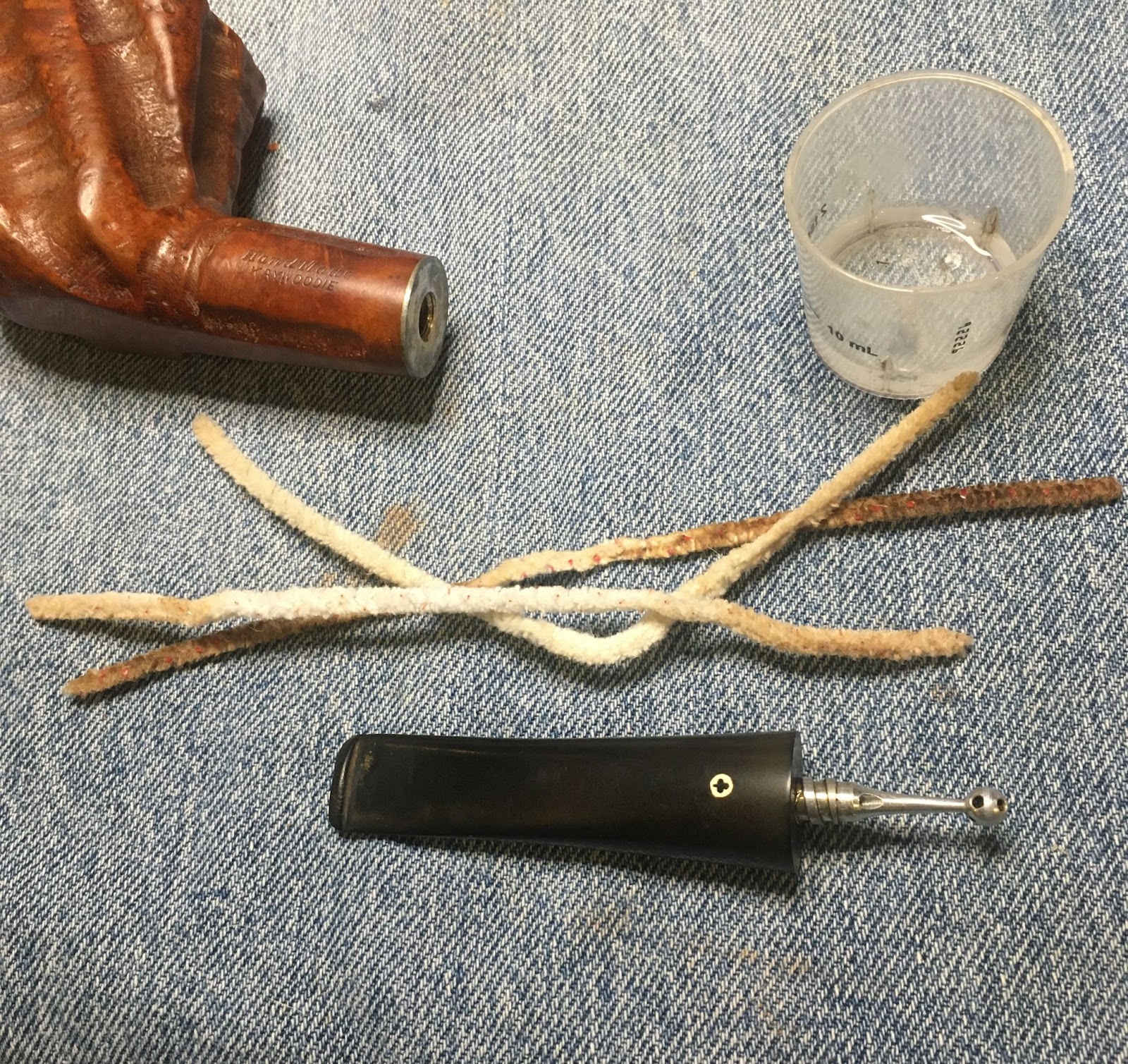

I gathered the reaming crew: The pipNet with the #2 and #3 bladed, Smokingpipes Low Country knife, General triangular scraper, 220 sandpaper wrapped wood dowel and the 320 sandpaper wrapped Sharpie marker.

With the crew all ready I started with the PipNet with #2 blades attached. It was far smaller than the tobacco chamber but working in steps is easier that taking a large step.

It reminded me of the old saying, “How do you eat an elephant?”. “One bite at a time.” The #3 blades cleaned up the chamber most of the way and required little scraping with the knife or scraper.

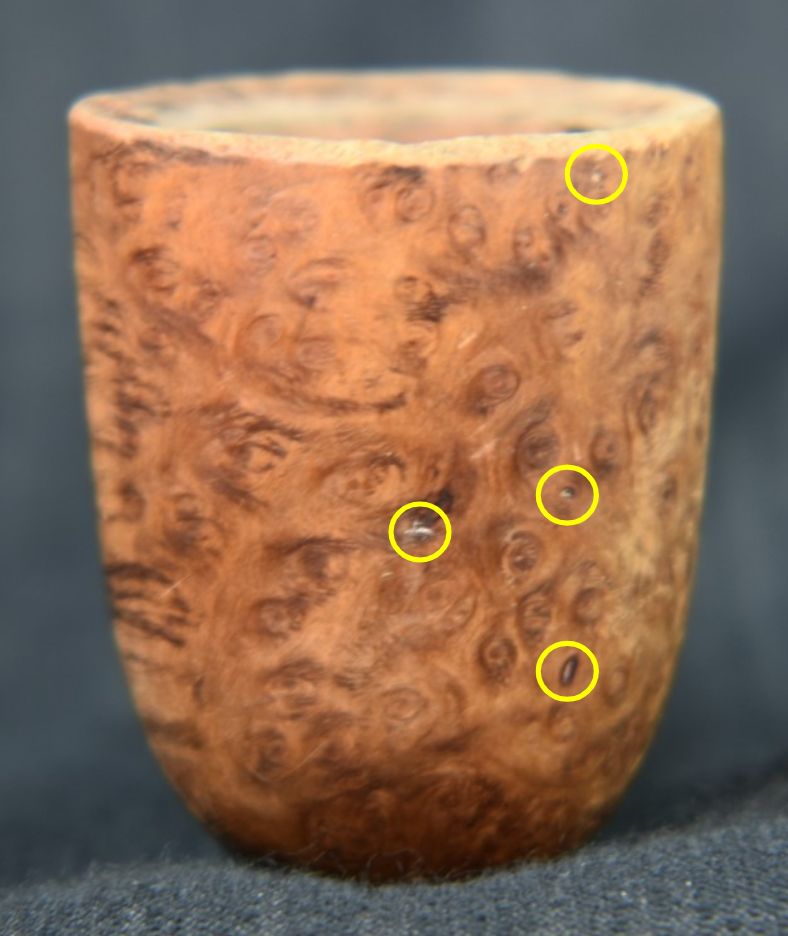

The chamber was sanded to bare briar with the 220 sandpaper and finished with the 320 sandpaper. There was a strange groove cut into the chamber from nearly the top to the bottom. The groove was about 1-2 mm wide and not a mm deep. I tried to sand it smooth without getting the chamber out of round.

I normally would have addressed the rim at this time but the rim had fine rustications and a smooth surface immediately out from the chamber. I did not want to change the rustication so opted to try to remove the lava with the Murphy’s Oil Soap scrubbing. I did want to get some idea for how fouled the airway of the shank was. I moistened several cotton swabs with alcohol and tried scrubbing the shank. They came back very darkly stained with tar and yuck (the technical term for black tar like smoking residue). That told me that the shank cleaning would be a difficult one. The Kaywoodie mortise being aluminum meant that it was difficult to do any scraping of the airway with a dental scraper.

I took the stummel to the sink for scrubbing. At the sink I used Murphy’s Oil Soap undiluted and scrubbed the stummel with a medium bristle toothbrush. A surprising amount of old dirt and grime came off in the scrub.

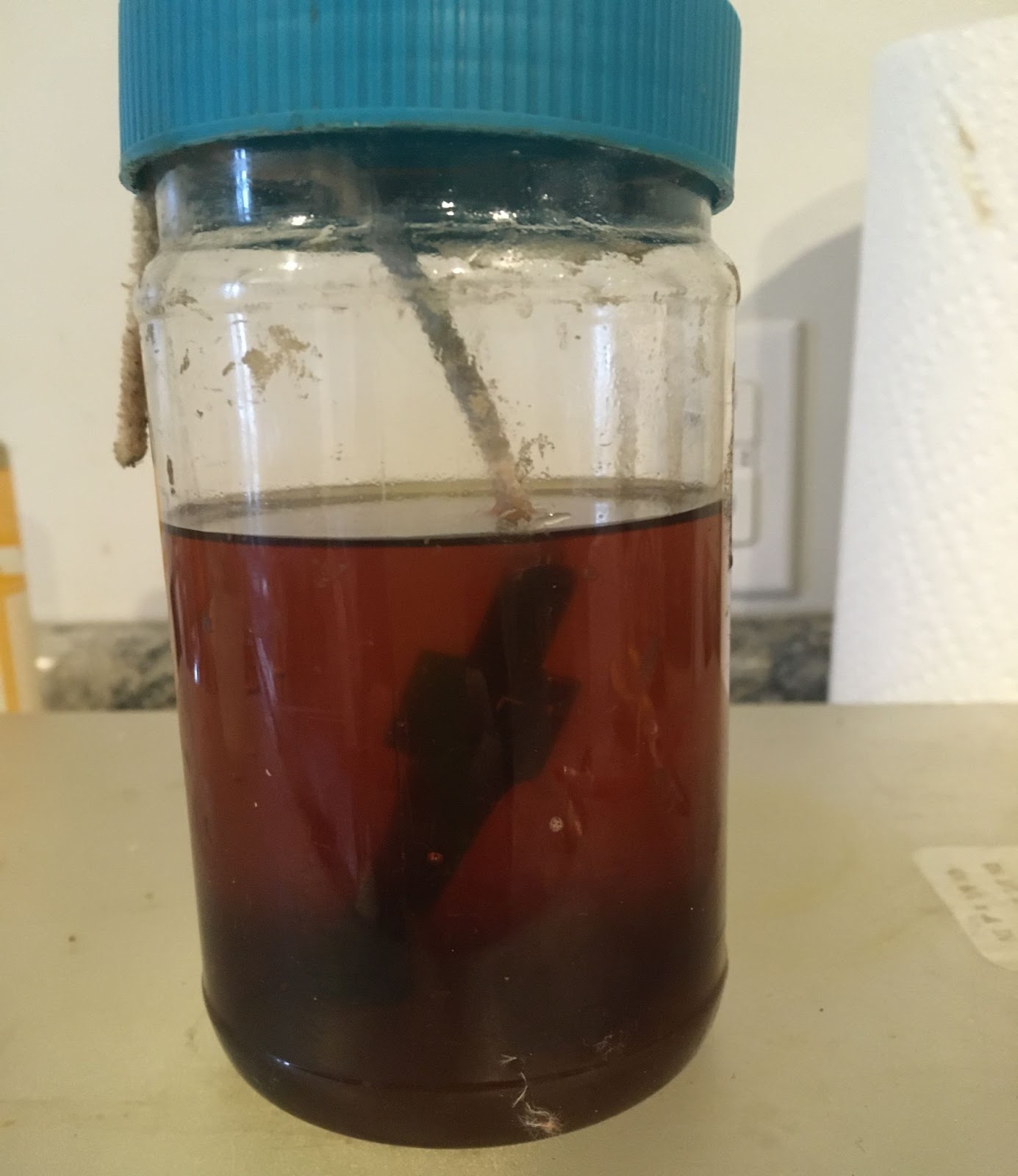

The rim was scrubbed with the toothbrush initially then I graduated up to a brass brush to remove the lava without damaging the rustication. The stummel was rinsed with warm water and dried with a cotton dish towel. I then poured about 5 ml of 95% ethyl alcohol into the bowl. I let this flow into the shank without pouring it out. I then scrubbed the airway using a nylon shank brush allowing the alcohol to soften and dissolve the accumulated yuck. This was then poured into a medicine cup. The results were very dark and indicated that the shank was full of yuck.

I returned to the workbench to do what scraping I could with the dental scraper. Anything I could get out with the scraper was worth several alcohol/shank brush scrubs.

The scraping alternated with alcohol and nylon brush scrubbing. An abbreviation that comes to mind is TMTC, meaning too many to count. TMTC later the cotton swabs were finally yielding less and less yuck.

With the shank finally cleaned out I returned my attention to the exterior of the stummel. I wiped the exterior with a make-up pad wetted with 95% ethyl alcohol. The briar did not appear to have been stained and not finished. I was hoping that it was just wax and grime that would be removed with the pad.

The alcohol pad came back with what looked like some sort of finish or wax, mostly from the carved areas. I decided to use an alcohol dipped brass brush to scrub the carved areas more thoroughly.

This resulted in removing much more, whatever it was that was, being removed. The stummel looked much cleaner. The only sanding that I did to the stummel was a slight beveling of the rim around the tobacco chamber to eliminate some of the charred wood from lighting the pipe. Since there wasn’t really anything to sand or micro-mesh on the stummel I gave it a coating of Before and After Restoration Balm worked into the rustications with a baby toothbrush and set it aside.

The stem had soaked up a bit of the mineral oil. I started with the 400 and 600 sanding sponges. I wanted to see if the tooth dents were bad enough to fill or if they could just be sanded.

The dents on top were minimal but the both would require filling with black cyanoacrylate (CA, super glue). I placed a small drop of the black CA on the dent filling it. I then spritzed the drop with a CA drying accelerator. This dries the CA almost immediately. I then filed the drop smooth. A second layer of CA was then spread over the entire area from the button back up the stem for about 1/2 inch (1 cm).

This was then smoothed with a flat needle file, followed by the 400 and 600 sanding sponges. The wider area helps blend the filled dents better than just having CA spots on the vulcanite.

I admit to doing a poor job at photo-documenting the process with step by step photos of both top and bottom. The results look good though. Next was sanding the stem with the full series of sanding sponges from 1000-3500. Between each sponge I applied a finger dipped in mineral oil to the stem then wiped it off with a paper towel.

After the sanding sponges I used micro-mesh pads 4000-12000 to further polish the stem. Between each of these pads I applied a drop of Obsidian Oil, rubbed it in with a finger and wiped the stem off with a paper towel.

The final polishing was done with Before and After Fine followed by their Extra Fine Polishes. These were applied with a finger and rubbed with a soft cotton cloth.

I had allowed the Before and After Restoration Balm to dry overnight on the stummel. It had formed a slightly tacky textured finish that I hand buffed off with the inside of an athletic sock. I do love the way the terry-cloth of a sock removes the excess balm.

The pipe was reassembled and taken to the buff for several coats of carnauba wax. I tried to apply very light coats of wax to the rusticated carved surfaces using the edges of the buffing wheel to work the wax into the carvings. It seemed to work well. After the application of was I replaced the waxing wheel with a clean buffing wheel and went over the carving again hoping to draw out excess wax with the clean buffing flannel. The waxing wheel was placed back on and I applied a final coating of carnaube to the smooth surfaces carefully avoiding the carvings.

Overall this Kaywoodie HandMade tapered stem turned out very well. It feels very good, substantial but good in hand. My fingers seem to line up nicely with the carvings making it quite comfortable to hold. This is probably good because clenching this pipe would be difficult with it’s 2.52 ounce weight. The other dimensions are as follows:

Length: 6.16 in./

Bowl Height: 2.20 in./ 156.46 mm

Chamber Depth: 1.96 in./ 49.78 mm

Chamber Diameter: 0.85 in./ 21.59 mm

Outside Dimension (side-side): 1.67 in./ 42.42 mm

Outside Dimension (front-back): 1.89 in./ 48.01 mm

Yes, she is a big girl, some might even refer to this pipe as lumber. Were I a betting man, I would wager that she smokes very coolly. I do hope that you have found this to be useful and entertaining. If you enjoy this sort of thing, please click the like and subscribe. I thank you for reading the ramblings of an old pipe lover.

Below are some of the finished photos of the Kaywoodie HandMade taper stem.