Photographed and written by

John M. Young

For the pipe connoisseurs out there the name Dunhill evokes strong feelings, rightfully so, of quality and workmanship. I have yet to have the honor of restoring or smoking a Dunhill pipe so I feel inadequate to describe them. I can say that there are a few brands owned by Dunhill which I have had the pleasure of restoring: These include Hardcastle, Parker and now Masta. Yes, I know this does not make a Masta a Dunhill any more than a Mazda car was a Ford due to Ford’s ownership of a large amount of Mazda’s shares. The fact remains that so far, this is as close as I have gotten to an actual Dunhill. This Masta was purchased via eBay from a seller in Vilnius, Lithuania and thus took considerably longer to ship than a typical State side transport. I think it was worth the wait. The pipe arrived and was photographed as it appeared after the unboxing. It is stamped MASTA over PATENT over STANDARD with 45F left of the stamping on the left shank of the pipe. On the right shank is MADE IN LONDON over ENGLAND.

The pipe appeared to have been cleaned though not restored . This made for what looked like an easy relaxing restoration. The tobacco chamber was mostly clean. The Stem had some oxidation and a single bite mark on the bottom of the button. There were no serious dents or scars on the briar.

Background

As said earlier, I’d not be a good pipe snob, never having laid hands on a Dunhill. When asked what my favorite pipe is, I’ve been known to reply, “The one between my teeth.” When asked about my favorite tobacco, the reply is similarly “The one in my pipe.” I have found that I prefer some pipes, tobaccos and people over others. Generally, the rule is that I favor those which agree with me. Aesthetically this Masta agrees with me. Historically, I find the lack of information about Masta disagreeable. Pipephil.eu has a few photos of stamping which verify this pipe is indeed a Masta but little else.

(Mas — Pipes: Logos & Markings)

Turning to pipedia.org, I found a short blurb followed by a longer blurb. The first is included below:

“Masta was a brand founded around 1900. When Parker Hardcastle Limited was formed in 1967, they also incorporated the Masta Patent Pipe Company. From this point this was a Dunhill / Parker / Hardcastle offshoot, primarily for the scandinavian market. The brand no longer appears to exist. Masta was at the end rarely the equal of a Parker.” (Masta – Pipedia)

Wow, so between 1900 and 1967 Masta apparently did nothing. They were then taken over by Dunhill, along with Parker and Hardcastle, where they produced sub-Parker quality pipes for some “scandanavian”s who couldn’t even afford to capitalize Scandinavia. Hmm, not too impressive thus far.

The second blurb appeared to have been taken from another source and was footnoted in the “References” at the bottom of the pipedia.org page. Wanting the original source so, I followed the link to the below quote:

“Produced in London by Masta ( Dunhill ). Masta Patent Pipes Company was founded around 1900 to London. The firm suffered numerous adversities (the factory was destroyed by a bombardment in 1941, during the second world war). the mark Masta was acquired in 1946 by Parker Pipes Co. (Dunhill) and the production continued in the establishment Parker-Hardcastle, next to St. Andrews Road. What the pipes Masta (how Hardcastle and Parker ) can be considered “second lines” of Dunhill (or exemplary not perfect, with defects that cannot be signed from the mother house) is common and very diffused opinion. To this opinion I habitually conform me. It is necessary to specify however that this hypothesis is controversial and it has never been confirmed. The only certainty seems to be that Parker , Hardcastle and Masta belong to Dunhill and the pipes they are produced in the establishment Parker-Hardcastle . Parker and Masta have in common usually forms and numbers of shape.” (Masta (Dunhill) Patent Standard – Very nice English briar pipe – No Reserve | #292597597)

Well, that was better than the first blurb even with the apparent use of Google translate to convert it to English. There were discrepancies among the dates, 1946 and 1967 for the purchasing of Masta by Parker and or Dunhill. This still was a more objective version of Masta history.

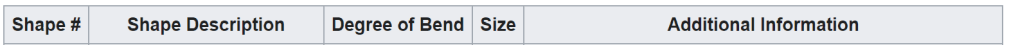

Pipedia.org also has a nice Masta shape chart:

I still had trouble with the whole notion of a company as illustrious as Dunhill having to wage economic warfare on companies producing far lower quality products. I couldn’t imagine many Dunhill aficionados ever hearing the announcement, “Attention K-mart shoppers…” during their pipe shopping excursions.

It was in a blog on Steve Laug’s Rebornpipe.com that I came across Robert M. Boughton’s blog “Identifying, Categorizing and Refurbishing a Masta Diplomat” (Identifying, Categorizing and Refurbishing a Masta Diplomat | rebornpipes). Robert did a wonderful job explaining the history of Mast in a reasonable way which I found enthralling. I highly recommend that blog as a read if you are interested in the history of the Masta Patent Pipe Company. With that I felt like I now had a functional knowledge of the brand and turned to the restoration.

The Restoration

As usual I began with a clean denim piece to protect the work surface.

The team was assembled; the PipNet with #2 blades, Smokingpipes Low Country Reamer, General triangular scraper (with the tip ground round) and 220 sandpaper wrapped around a wood dowel (AKA a 20 gauge shotgun magazine plug).

The PipNet was used predominantly for the reaming with the other two scrapers just to clean off stubborn spots.

The completed reaming showed slight damage to the rim.

Once reamed the chamber was sanded with the 220 sandpaper. No damage from heat was observed .

The stummel was taken to the sink for a scrub with a nylon scrub brush and undiluted Murphy Oil Soap. The soap was rinsed with warm water and the stummel dried with a cotton hand towel.

Back at the workbench the stummel was wiped with a make-up pad dipped in 95% ethyl alcohol. Very little color, existing finish, came off. The grain patterns could be seen much better at this time and looked very nice. I was very tempted to contrast stain the stummel here but thought that that would not hold true to the nature of this pipe.

The shank airway was filthy and full of accumulated tar. After numerous alcohol dipped cotton swabs, I decided to try a cottom/alcohol soaking to remove the tars. The tobacco chamber and shank were stuffed with cotton and 95% ethyl alcohol was added to the cotton filled passages with a disposable pipette to the point of saturation. The alcohol was allowed to work on dissolving the tars overnight.

The next day the cotton had absorbed much of the tars liberated from the briar by the alcohol as it evaporated.

The cotton was removed and the cleaning resumed and went at a much faster rate.

The surface of the stem was scrubbed with Soft Scrub cleanser on a make-up pad.

This produced very little discoloration on the pad indicating that the stem was not heavily oxidized.

The button needed a little bit of reconstructive work. I used cheap transparent tape to cover the button proper and confine the black cyanoacrylate (CA, super glue) to the stem where I wanted to fill the dent. I prefer the cheap tape as the more expensive 3M brand Scotch tape softens and dissolves with exposure to CA drying accelerator.

Black CA was applied to the area to be filled with a wide zone for blending.

The black CA was spritzed with a CA drying accelerator and filed smooth.

The taping was reversed – covering the new patch and leaving the area to be filled uncovered.

The black CA was applied to the dented spot on the button, building up the area. This was then spritzed with a CA drying accelerator. The tape was removed and the fill filed smooth and the button reshaped.

The newly repaired button was sanded smooth and inspected to see if additional CA would be required.

The stummel was very clean and free of any flaws except for one small pit. This was filled with brown CA and allowed to sure on its own. The stamps had been taped with painters tape to preserve them during the upcoming sanding.

The stem and stummel were sanded with a series of sanding sponges from 600-3500 grit. Between each sponge the stummel was wiped with a make-up pad wetted with alcohol. The stem was rubbed with mineral oil and wiped with a paper towel between sanding sponges.

After the final wipe downs from sanding the pipe was worked with micro-mesh pads from 4000-12000 grit. Between sponges the stummel was again wiped with the alcohol wetted make-up pads while the stem now received a rubbing with Obsidian Oil and a wipe with a paper towel.

The pipe was given a coat of Before and After Restoration Balm and allowed to sit for 30 minutes.

With the balm doing the magic that it does for 30 minutes the remaining mysterious elixir was wiped from the pipe with an inside out athletic sock.

The final steps were to take the pipe to the buffer for several coats of carnauba wax and a final hand buffing with a microfiber polishing cloth.

I have to say that I think this Masta Patent Standard 45F is a beautiful specimen. The graceful curves are well proportioned and elegant. It appears to be a well crafted pipe with only one noticeable pit in the briar. If this is what a Dunhill “second” looks like, I am going to be very impressed if I ever get to work on a Dunhill. I retained the natural finish of the briar and it is quite lovely with attractive bird’s eyes and a nice flame grain on the front. The stem polished up well and the high gloss black is a pretty contrast to the natural briar. I am sure that this pipe will be a grand smoker and bring someone many years of enjoyment.

The dimensions of this Masta 45F Patent Standard Bent Billiard are:

- Length: 5.63 in./ 143.11 mm.

- Weight: 1.49 oz./ 42.40 g.

- Bowl Height: 1.79 in./ 45.47 mm.

- Chamber Depth: 1.60 in./ 40.64 mm.

- Chamber Diameter: 0.70 in./ 17.78 mm.

- Outside Diameter: 1.42 in./ 36.07 mm.

I do hope that you have found something here useful to your own pipe care, maintenance or restorations. If you like this sort of thing, please click the like and subscribe buttons. Thank you for reading the ramblings of an old pipe lover.

Below are some photos of the finished Masta Patent Standard 45F.