Photographed and written by

John M. Young

I had never had a Peterson Donegal pipe prior to the arrival of this 106. I know, crazy right? I mean the Donegal Rocky has been a staple of the Peterson line since 1945. I love the look of the texture with it’s craggy appearance and contrast stained briar. I could not speak to the “feel in the hand” until I actually laid hands on this pipe. Let me say, it is very nice. My neglect of the line was not due to purposeful malice, just an unwillingness to spend as much money as the pipes were commanding. Also, the fact that rustication has changed dramatically over the years. I’ll get into that more in the “Background” but let’s just say the “pineapple” years were not pretty. This rustication is what I think of when I think Donegal Rocky.

This pipe is stamped Peterson’s (the top portion of this stamp is weak) over “DONEGAL” ROCKY. Offset to the left is 106 with MADE IN THE over REPUBLIC over OF IRELAND to the right side of the stamping area. The stem was a very tight fit upon arrival from Brooksville, Florida. Maybe the humidity of that southern state was the cause. Below are some photos of the pipe upon arrival. Well, not quite as “upon arrival”. When the pipe arrived the stem was very much stuck in the mortise. A visit to my freezer for an hour allowed me to extract the stem easily. Once warmed it was a very tight fit. I did not completely reinsert the stem into the shank for fear of damaging the pipe.

The pipe looked like it was generally in good shape. The stem was heavily oxidized and had a pattern to the oxidation that I found amusing. As if the previous smoker had antioxidant saliva. The stummel was dirty with about 50 years worth of grime. The tobacco chamber was well caked but not to excess, just definitely smoked. The rim had a fair amount of lava, again indicative of a well used and loved pipe. This looked like a nice straight forward restoration.

Background

I recently restored a Peterson Dunmore 606 Pot and wrote the following in that blog: “As much as I love the history of the Kapp and Peterson company and Peterson pipes, I will not get into that other than give you resources to read the history for yourself. I will delve into the Dunmore, or Dunmoor line of pipes at greater depth.

For a great history Mark Irwin and Gary Marlburg’s book is a must read for a Pete Geek.

(Available at https://www.smokingpipes.com/accessories/books/moreinfo.cfm?product_id=471478) Given the price is a bit high but worth every penny for a Peterson aficionado.

The next site is pipedia.org’s History of Peterson by Jim Lilley (Peterson – Pipedia)

Lastly the pipephil.eu site for all things logo: Peterson: historical pipes — Pipes: Logos & Markings (pipephil.eu) They also have a few other links to things like the Peterson timeline and P-lip information.

Now to the stuff regarding this pipe: A Peterson Dunmore. I refer to Mark Irwin again here and his blog, Peterson Pipe Notes. I can wholeheartedly recommend the free at

https://petersonpipenotes.org/ Yes, you will get emails but only for things like the weekly blog post and occasional Peterson pipe drops (like the Peterson Pipe Notes Pipe of the Year) or offers for cool Pete Geek merchandise. Anyway Mark has an article on the Dunmore line that is great. https://petersonpipenotes.org/226-documenting-the-dunmore-system-and-classic-lines/

I will include the text here in its entirety but recommend the link for the photos. This is used with permission of the author (thank you Mark).”

The above holds true for this blog as well except take out the “Dunmore” and add “Donegal Rock” in it’s place.

Once again I use Mark Irwin’s Peterson Pipe Notes as a primary source for this pipe. His Blog “148. The “Rocky” History of the Donegal Line” (https://petersonpipenotes.org/tag/peterson-donegal-rocky/) is a wonderful explanation of how the line originated and changed over the years. I include it here in it’s entirety, with permission of the author (personal email).

I recently acquired for study an amazing NOS (new/old stock) Donegal Rocky 01s with its box, sleeve and brochure. Hallmarked with a Celtic lower-case n for 1979, it’s a first-year release of this marvelous ‘short dutch’ bowl shape and convenient reason to take a look back at the long history of Peterson’s iconic “Donegal Rocky” line.

The “Donegal Rocky” (in quotation marks), released in 1945 or so, was Kapp & Peterson’s first rusticated line. Not that K&P hadn’t rusticated pipes previously, they just that they hadn’t devoted an entire line to rustication. And they were apparently proud of it, because they gave it a sterling mount along with a black finish and white-stamped P on the mouthpiece.

It was part of K&P’s “Product Line,” what I call gateway pipes and others might call an entry-level pipe, as you can see in this shape chart from the 1945 catalog. Like the Shamrock (European version) and “K,” it was originally a fishtail line.

For nearly thirty years, from 1947 until 1975, the line continued uninterrupted, black rusticated finish with fishtail mouthpiece and sterling band.

from the 1976 Associated Imports Point-of-Sale Brochure

Then in 1976, just a year out from their Centennial celebration, Peterson (in an expansive mood) pushed the Donegal up a notch, giving the line a P-Lip. The 1976 engraving doesn’t show it, but you can just glimpse a new, deeper rustication in the (still black) 1978 Associated Imports chart:

This rustication was done by a carver in Dublin, Paddy Larrigan told me this past June in Sallynoggin. The artisan did all of Peterson’s fantastic rustications from the period: the classic “Pebble Rustics,” the early Sherlock Holmes rustics, the Bond Street of Oxford Premier Systems, and the sterling-band P-Lip Donegals.

And that’s where this 1979 01s comes in handy, because we can see with much greater clarity the rustication as well as the details of a “Donegal Rocky” at its pinnacle of engineering and finish:

It’s worth remarking concerning the removable stinger. This spike-ended aluminum tube is easily removed, leaving the P-Lip mouthpiece strictly a graduated-bore regulation affair.

If I were more dedicated, I’d smoke this pipe a few dozen times with and without the stinger and give you a report on what purpose it serves. I wonder if the craftsmen at the factory installed the stinger to approximate the effect of the older bone tenon extensions routinely attached to Classic Range Dublin & London, Classic and Premier lines? With or without the stinger, the pipe smoker should enjoy the benefits of the “Sub-System,” which I talk about at length in The Peterson Pipe. As it is, I’ll leave that to someone else, and happily report their findings.*

Here’s the COM stamp, showing Peterson’s love of quotation marks (seen also in the “SPORTS” line) as well as a closer look at the stain and rustication technique:

Sometime between 1978 and 1980 the sterling band was dropped to a nickel band and the P-Lip abandoned in favor of the Donegal’s traditional fishtail, all of which may (or may not) indicate a lessening in the quality of the rustication.

Seen above from the 1981 Mark Twain brochure, the sterling band resurfaced, this time with the line’s first change in stain color to what some of us have in our rotations or remember: the contrast brown over black (seen in the dutch 339 hallmarked for ’81 below). The catalogs indicate some fluctuation from sterling to nickel bands on through the Late Republic era (1969-90) into the Dublin era (1991-2018), with the sterling being used (as happens so often with Peterson lines) in conjunction with a P-Lip in the 1997 catalog, but also in that year available with a nickel band and fishtail.

The dublin 120 seen above is from ’94, and as you can see, while the rustication technique is nearly identical to that of the ’81 dutch billiard, the stain color has changed for a third time to burgundy-over-black, which seems to have been the standard during most of the early Dublin era.

Sometime near the beginning of this century the Donegal was down-graded again to its original “Product” or gateway status by a nickel band and fishtail mouthpiece as seen in this B7, and while the stain remains the same, it looks less craggy:

Things would grow steadily worse in the following years, however, as the gawdawful pineapple rustication took hold, so that by around 2010 the Donegal was reduced to the etchings seen on this B39:

With the return of in-house rustication earlier this year, things are looking up for the Donegal, at least just a little, as you can see in this current 80s:

The finish and the rustication are, so nearly as I can tell, identical with that used on current rusticated SH pipes, so that’s something, right? I don’t think I’d call it a Rocky anymore, but at least it still has a vulcanite mouthpiece, a plus.

As for the future of the line—or the name—I couldn’t hazard any guesses. In the ideal Peterson of my imagination, the line would assume the craggiest crags, sharp textures and brilliant obsidian finish of the last batch of Rosslare Rusticated pipes, along with—of course—a vulcanite P-Lip. In the meantime, just to have it around, as one of the bedrock Peterson lines for almost 75 years, will do.

According to Mark’s well documented history of the Donegal Rocky line this pipe shouldn’t have the contrast stained black/brown that I see as that didn’t come about until the later 1970s. I emailed Mark asking him what he thought about my restoration of this pipe and at publication I have not heard back. I assume he and his wife are shipping out the most recent Peterson Pipe Notes pipe stand, so I understand his busy schedule. That is if my interpretation of the worn silver hallmark is correct.

The silver hallmark that I see on this pipe is a lowercase e as seen in this photograph:

Now an argument could be made for either an e, c or o. Respective dates would be 1972, 1970 and 1980. The o would move the pipe closer to the black/brown stain age range of 1981 as mentioned in the Mark Irwin blog above.

The Restoration

The restoration began as normal with a clean denim piece. I then started work on the stem.

The first job was to buff the stem with 0000 steel wool to remove the hard shiny oxidized coating.

This allowed the OxyClean solution easier and faster action at softening the oxidation. The stem was left to soak in the Oxy for an hour or so.

Next came the reaming and the reaming tools were gathered.

The lion’s share of the work was done with the PipNet reaming tool with its #2 and #3 blades. This cake was very hard and dry and the tobacco chamber size was a very tight fit for the #3 blade so scraping was required to allow easier reaming with the PipNet.

Eventually the chamber looked mostly cake free.

I was pretty sure that I should be receiving some sort of tax subsidy for the carbon sequestration I would be responsible for by sending this pile to a landfill.

Upon sanding the tobacco chamber I discovered that the cake had not protected the chamber as well as I would have thought that the previous owner was a puffing madman. The inside of the chamber had light spiderwebs due to heat damage both to the left and right front. Further sanding made it so that I could not feel anh roughness but I could still see the spiderwebs. A quick message and photos were sent to Steve Laug for a bit of advice. I wasn’t sure that this would need a waterglass, J.B.Weld of just a bowl coating. Steve got back to me quickly and said a bowl coating would probably be sufficient.

I proceeded to the scrubbing. This was done with undiluted Murphy Oil Soap and a medium toothbrush.

After the exterior was scrubbed I used a bit of Dawn dish soap with a nylon shank brush to see how bad the airway of the shank was. It was pretty bad. The stummel was thoroughly rinsed inside and out with warm water and dried with a cotton hand towel.

Back at the workbench I poured 3-4 ml of 95% ethyl alcohol into the bowl and allowed it to flow into the shank. I scrubbed with a nylon shank brush and the alcohol then poured the alcohol into a medicine cup. Yeah, there may be North American megafauna stuck in that tar pit.

I scraped the airway with a dental scraper to remove as much of the tar as I could get out. Repeated alcohol and shank brush scrubbings yielded more dissolved tar.

Eventually the airway was cleaned and the smell of old smoking residue disappeared.

The stem was retrieved from the Oxy and I began cleaning it with SoftScrub on make-up pads.

It eventually was rid of the majority of the oxidation at least from the button. Which was the area I needed to work on. The button area was filed and sanded with a 320 grit sanding sponge.

I moved on to a 400 and 600 grit sponge to further smooth the stem surface. There would need to be some filling of dents with black cyanoacrylate (CA, super glue).

The CA was applied then spritzed with a CA drying accelerator. The quickly cured CA was then filed and sanded with the above mentioned sanding sponges.

This was repeated until the fills were smooth.

With the button reshaped and filled I cleaned the airwair of the stem. The previous owner did apparently use a pipe cleaner through the stem as it was not nearly as fouled as the shank had been.

Next came the polishing of the silver. I used a Cape Cod Metal Polishing Cloth on the silver band. I love the smell of this product and it works well too.

The silver had a respectable shine but there appeared to be a film of surface flaw to the finish. I figured that I would spend more time with that later.

There was little to do with the stummel other than to clean it thoroughly. I used a baby toothbrush to work Before and After Restoration Balm into all of the craggy texture and let the balm work it’s magic.

I prepped the shank by wrapping it in painters tape to avoid stray sanding. The stem was sanded with a series of sanding sponges from 1000-3500. In between each sponge I dabbed a finger tip’s worth of mineral oil onto the stem and rubber it in. I then wiped the stem with a dry paper towel.

After about 20-30 minutes the Restoration Balm was wiped from the stummel using an inside out athletic sock.

I wasn’t sure which wax to use on such a wonderfully rough textured stummel. I opted to use the Decatur Pipe Shield No-Buff Wax. I cleaned the Restoration Balm from the baby toothbrush with 95% ethyl alcohol. I used the baby toothbrush to work the Decatur wax into the crags and let it dry for the recommended 10-20 minutes, as per the instructions on the label.

I then took the stummel to the buffer and swapped out the carnauba waxing wheel for a clean flannel wheel. I used the clean wheel to buff the N0-Buff wax. Yeah, I know…

Now to review: The stem before.

The stem after I had worked on it. There remained a serious amount of discoloration on the tenon end. This stubborn stuff required a less chemically subtle approach.

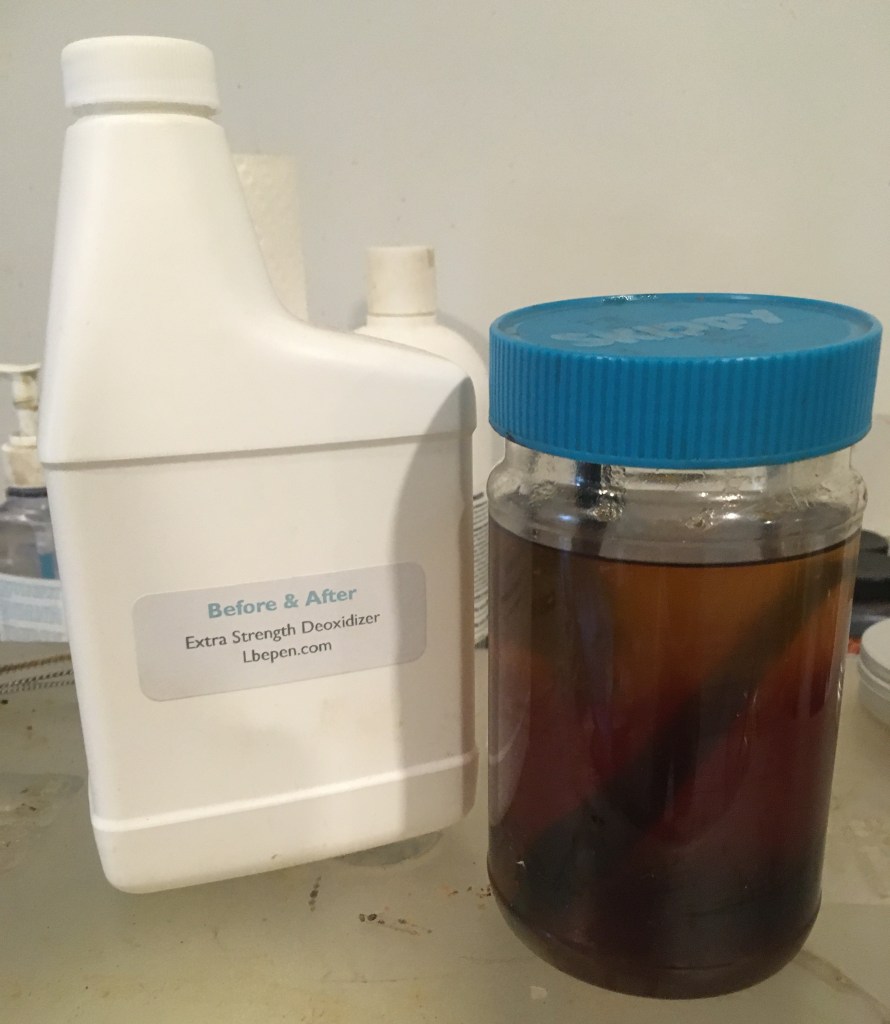

I went with a dip into the Before and After Extra Strength Deoxidizer. A pipe cleaner was inserted into the button end of the stem to suspend it from the jar top. I allowed the stem to soak in the solution for 2 hours.

After the 2 hours I removed the stem from the solution and let the excess solution drip back into the jar.

With the stem all drip dried, well not really dry, I wiped the stem with a coarse shop rag and ran several pipe cleaners through the airway. I then micro-meshed the stem with a series of 4000-12000 pads. Between each pad I applied a small drop of Obsidian Oil to the stem, rubbed it in with my finger tip and wiped the stem with a dry paper towel. I failed to photograph the micro-meshing. Darn old people.

The stem looked much better. If you can’t wait to see it, feel free to jump down a bit.

The spider webbing heat damage still needed to be addressed. I retrieved the maple syrup and applied a big drop to my finger tip. I rubbed this onto the surface of the tobacco chamber.

I then opened up a capsule of activated charcoal. I dumped the charcoal into the chamber, placed my palm over the rim and egan shaking the stummel distributing the charcoal powder and covering the sticky syrup. You can see the charcoal also left a very symmetrical spot on my palm. Having forgotten to plug the airway with a pipe cleaner I also got a nice coating of carbon powder all over the shank’s airway. Yay, more shank cleaning.

Below are the photos of the bowl coating.

I would say that my first Peterson Donegal Rocky restoration was a success. I think it turned out very well. I like the craggy appearance and feel of the pipe. The shape is a favorite of mine.The brown and black contrast stain was left intact and I think it still works . I was quite happy with the oxidation removal from the stem and the black vulcanite polished up nicely. The silverband looks as if it has experienced some trouble and I cannot get it to look bright and well, silver all around. I am sure this will be a great smoking pipe but will have to wait a couple of days for the coat coating to thoroughly dry. The dimensions of the Peterson Donegal Rocky 106 Billiard are as follows:

Length: 5.95 in./ 151.13 mm.

Weight: 1.54 oz./ 43.60 g.

Bowl Height: 1.96 in./ 49.78 mm.

Chamber Depth: 1.70 in./ 43.18 mm.

Chamber Diameter: 0.83 in./ 20.8 mm.

Outside Diameter: 1.58 in./ 40.13 mm.

I do hope that you have found something here useful to your own pipe care, maintenance or restorations. If you like this sort of thing, please click the like and subscribe buttons. Thank you for reading the ramblings of an old pipe lover.

Below are some photos of the finished Peterson Donegal Rocky 106 Billiard.

Some of the above “finished” photos were taken slightly out of sequence. Example: the bowl coating was added after some of the shots.