Photographed and written by

John M. Young

No, I am not getting political with this restoration and would greatly prefer you not to associate this restoration with Alexandria Ocasio-Cortez, also known as AOC, an American left-wing politician and activist, who has represented New York’s 14th congressional district since 2019, with a capital D after her name. I remain a card carrying Libertarian and want the record to show that I do not support Representative Cortez in any way. That said, this little pipe was probably made 70 years prior to the birth of Ms. Cortez and also owes her no affiliation. I think that covers the political and legal requirements of distancing myself from the people and parties involved in dismantling the Constitution of the United States.

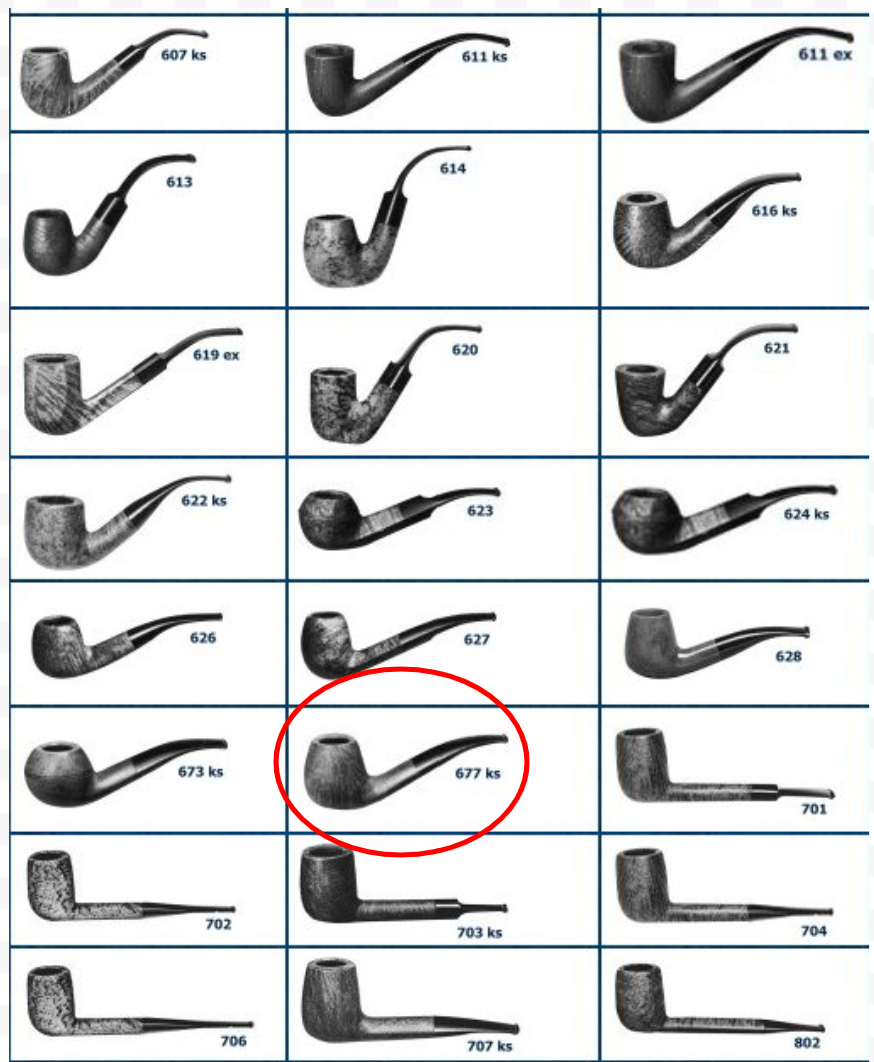

The original purchase was made from eBay due to what appeared to be two interesting pipes. In the photo below the two are on the left. The middle poker with the orific bit and the orange logo indicating a Dr Grabow Westbrook. Upon arrival this poker was very dirty with grime obscuring the briar almost completely.

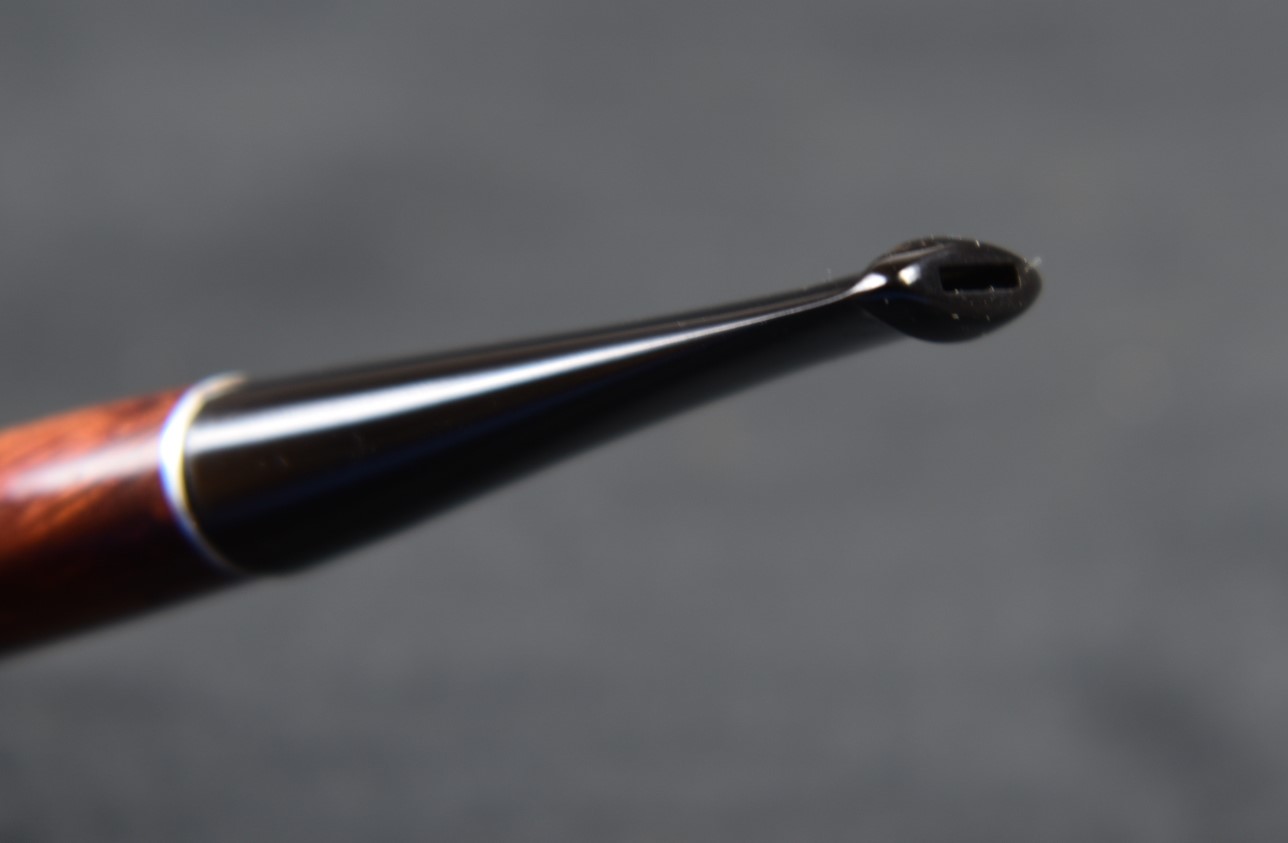

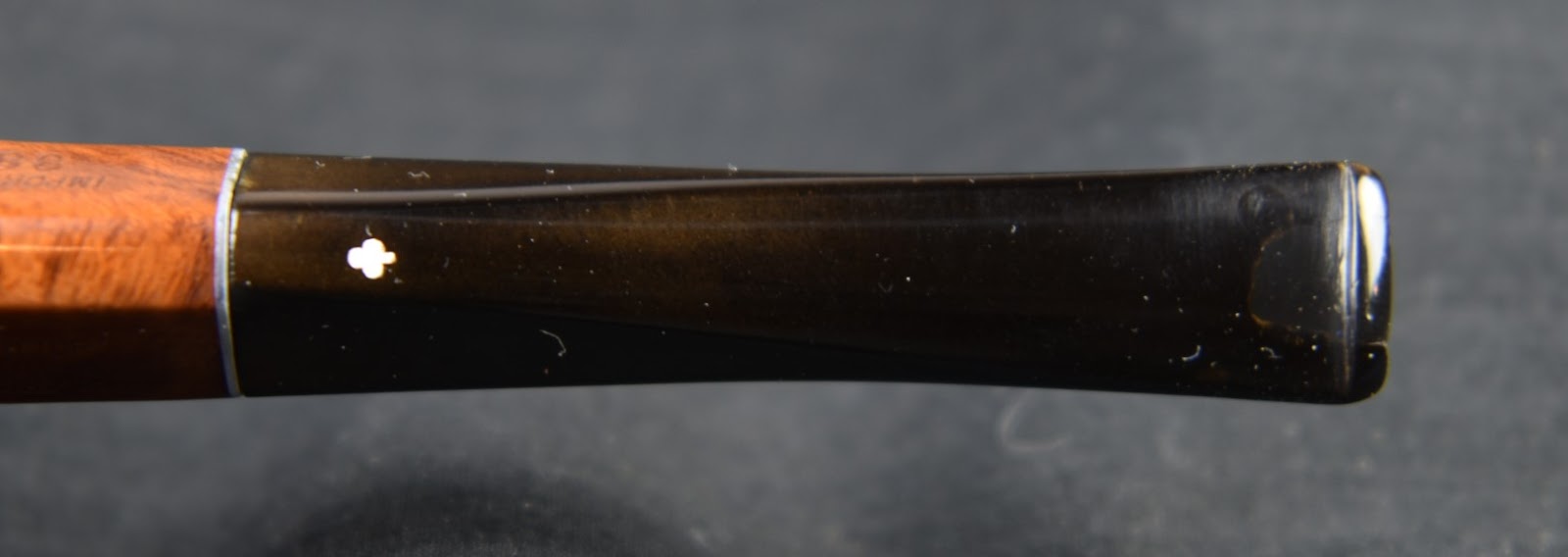

I wasn’t even sure if there was wood under there as I could not see much grain. The band read, STERLING SILVER but it appeared more like a black plastic. The stampings on the shank were clear showing what appeared to be a globe with latitude and longitude lines surrounding the letters A.O.C. on the left and LONDON ENGLAND on the right. The stem was stamped with a globe identical to the shank. The button was the type I’d seen on pipes dating to pre-1920. This old style bit is called orific. Steve Laug did a nice article on “Whatever Happened to the Orific Button?” (used with permission of S. Laug). Steve says the following of the pipes in his collection “are all older pipes with stems made of a variety of materials – amber, vulcanite, Bakelite and horn. In this group there are 45-50 pipes with this type of airway. All of them come from the mid to late 1800s and the early 1900s, literally another time and place.”

Oppenheimer Background

According to pipedia:

“The Oppenheimer Group was a British holding company, which through the Cadogan company had various pipe brands. It was founded in 1860 by Charles Oppenheimer, along with brothers Adolphe and David, and Charles’s brother-in-law, Louis Adler. They established connections with GBD in 1870. With business interests in Saint-Claude, Oppenheimer bought the Marechal Ruchon & Cie. factory, which from then on had two directors in London (Adolphe Oppenheimer and James Adler, son of Louis Adler), and two in Paris (August Marécel and Ferdinand Ruchon). In 1906, the group built a large factory in Saint-Claude, under the direction of Lucien Verguet, which led to the merger of Sina & Cie. and C.J. Verguet Freres. In 1920, the London factory took over A. Frankau, which produced BBB. Between the wars, Oppenheimer assumed the management of Ropp and used countless pipe factories around the world. In the 1970s, with the creation of Cadogan France, which had the GBD, Chacom, and Ropp brands, the last two being sold later, it separated from its English partner. [1] (https://pipedia.org/wiki/Oppenheimer_Pipe)

Wow, I had to read that paragraph several times to wrap my damaged brain around all that was written. I think the pertinent information to this pipe are the 1870 and 1906 dates. That would have been times when Adolphe was still alive and directing production. I am assuming here that a line of pipes with one’s name would occur while the one is still alive. It would also fit with the existence of the orific button on the stem of this pipe.

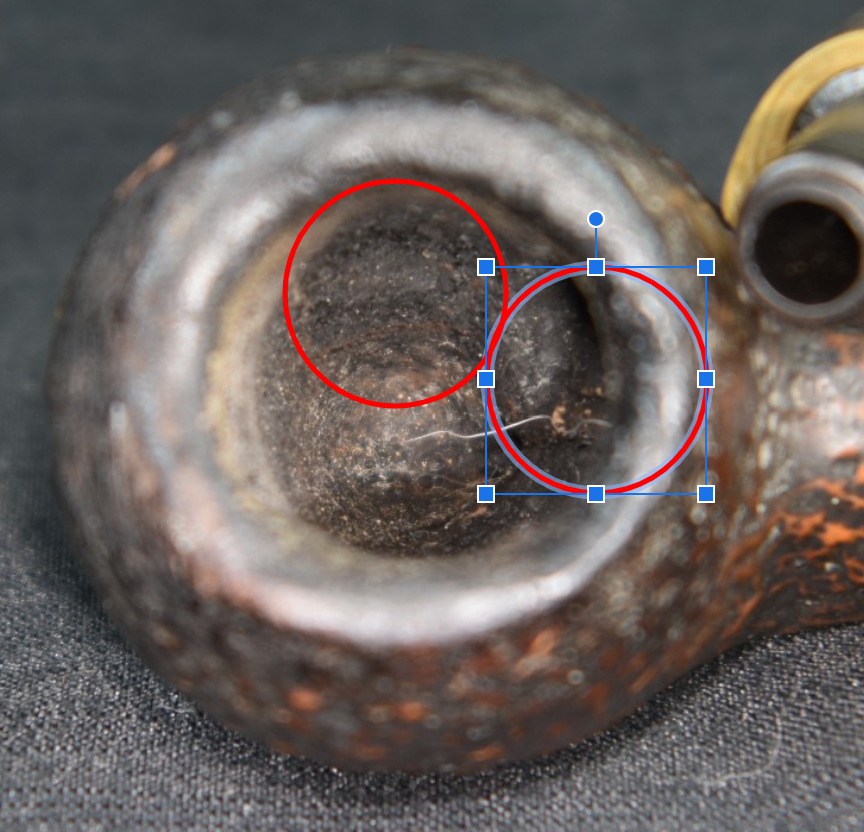

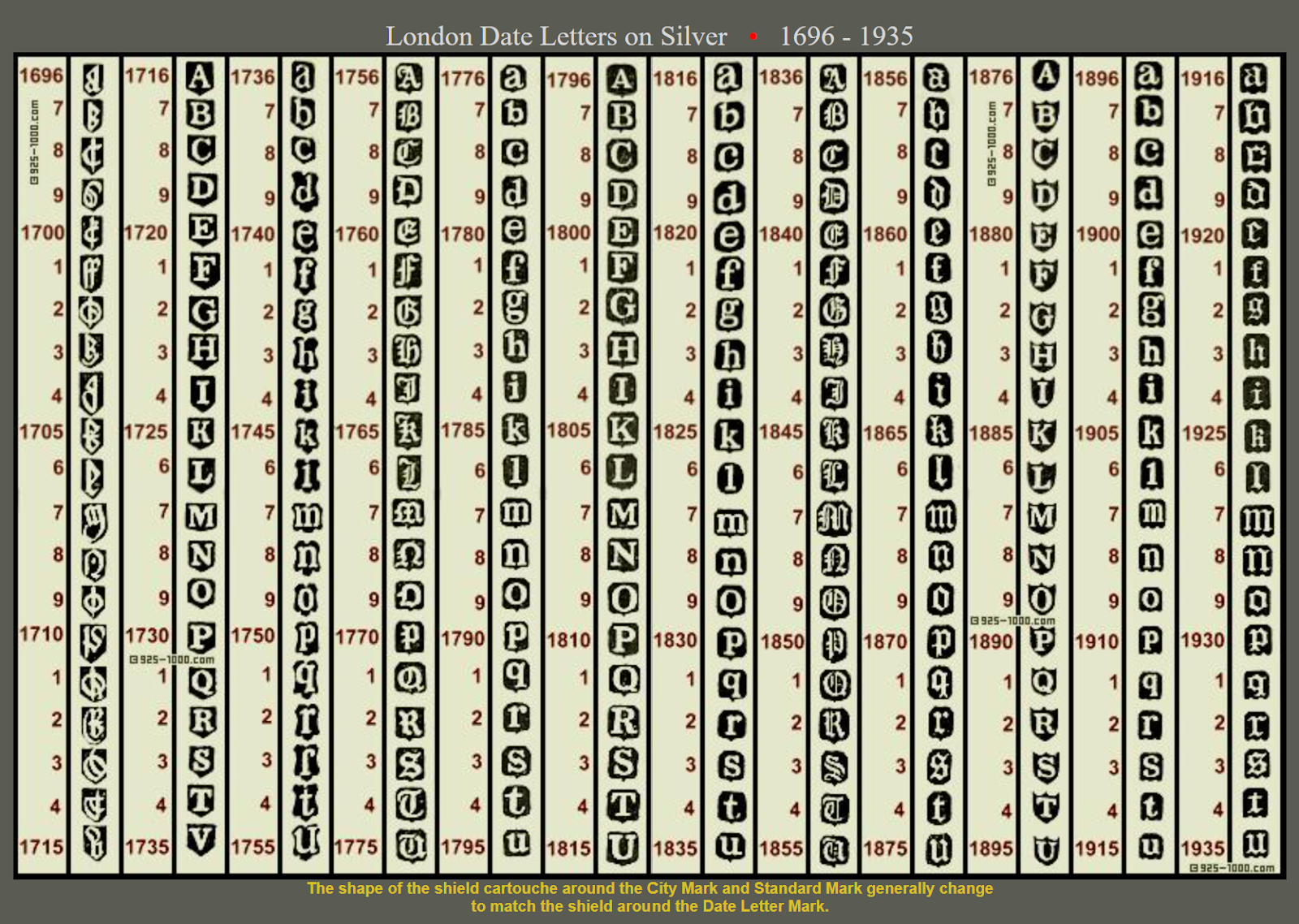

Looking closely at the stamping on the silver band the left marks are illegible but the right mark is definitely a capital “A”. Assuming that the pipe was indeed made in London, as indicated by the stamp, it would be relatively safe to assume the silver stamp would be that of the London assay office. Below are the London assay date letter associated with their respective years. 1876 is an “A”.

(https://www.925-1000.com/dlLondon.html)

I think the date stamp pretty much locks this providence of this pipe up. It is an Adolphe Oppenheimer Company poker made in London England with a silver hallmark stamp indicating manufacture date of 1876.

I came across a few other interesting tidbits while researching this pipe. I’ll leave the links for those who might find them interesting.

History of Vulcanite (https://pipesmagazine.com/forums/threads/history-of-vulcanite-article.37354/)

Smokingpipes.com example of an AOC (https://www.smokingpipes.com/pipes/estate/england/moreinfo.cfm?product_id=533251)

Pens Pipes and More video of an AOC Bulldog

(https://www.youtube.com/watch?v=5MkmBA4-F5c)

The AOC Poker as it appeared prior to any work being done.

The Restoration

As usual the pipe was moved to the workbench where it was placed on a clean denim piece. I was most interested in seeing what was under the many years of grime that shrouded the briar. That would have to wait a few more minutes.

Reaming the tobacco chamber was the first task to complete. The pipe had been recently reamed so there was little for me to do.

During this process the sterling silver band came loose. The band was very thin and I thought that it would be easily damaged.

After sanding the tobacco chamber, I needed to rid the rim of the lava deposits.

The lava was moistened with saliva and scraped with a sharp pocket knife. There were a couple of dents on the rim but it looked good and was free of charing.

Next was the moment I was most interested in, seeing what was under the grime. I scrubbed the stummel with undiluted Murphy Oil Soap and a medium toothbrush. The lather became gray with grime and was rinsed away with warm water. I also used a nylon shank brush and a small amount of Dawn dish soap to scrub the airway of the shank. This was also rinsed with warm water. The stummel was dried with a cotton wash cloth and returned to the workbench.

At the workbench the stummel was wiped with a make-up pad dipped in 95% ethyl alcohol. The pad changed color only slightly during the siping. There was briar under the grime, yay! The briar also had some nice grain. The scrub and wiping also revealed a fairly large pit at the bottom of the left side.

The briar grain at the back of the bowl was the most attractive.

I wanted to see how well the sterling silver would look after a cleaning. The Cape Cod Metal Polishing Cloths were selected for this. These clothes are moistened with chemicals which I did not want to affect the briar. I wrapped the briar with a layer of 3M Scotch tape. And proceeded to hand buff the band in situ on the shank inorder to retain the shape and protect the band.

After a good deal of hand buffing the black tarnish was removed and the underlying silver could be seen. Some areas of black stubbornly remained.

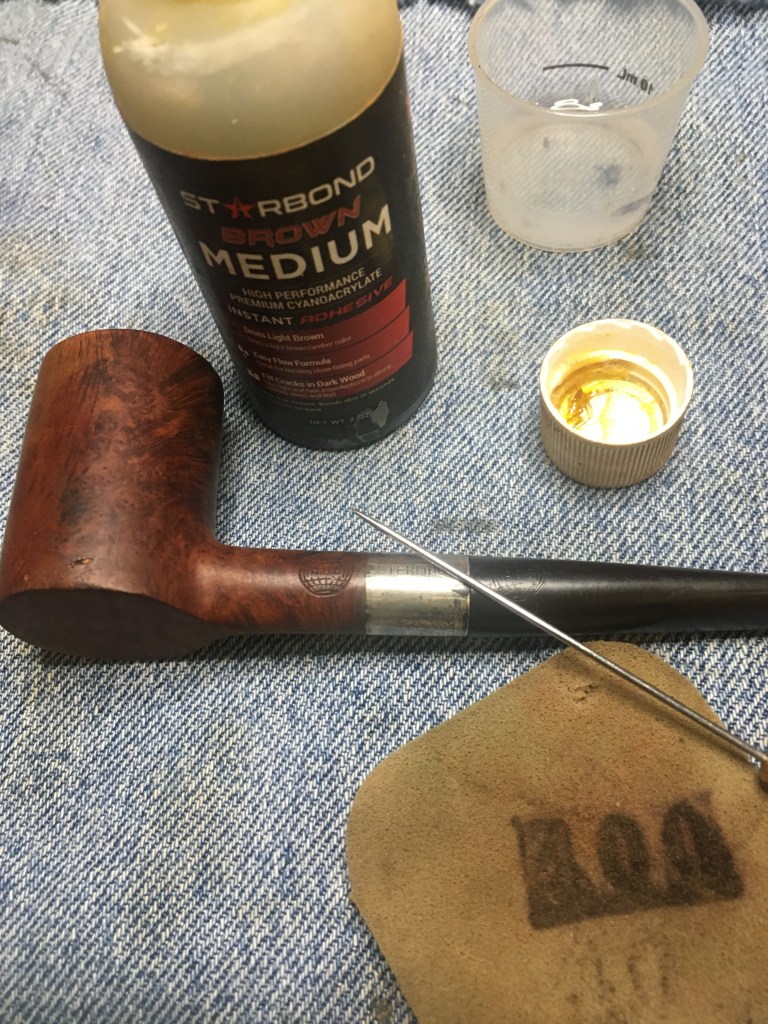

The pit on the lower left side of the stummel needed to be filled.

The pit was filled using brown cyanoacrylate (CA, super glue) and briardust. The pit was first picked out using a fly tying bodkin.

A drop of CA was applied into the pit. I used a dental scraper to scoop a small amount of briar dust and placed this onto the pit and used the back side of the dental scraper to press the dust into the wet CA and into the pit.

The fill was filed with a flat needle file then sanded with a 400 grit sanding sponge.

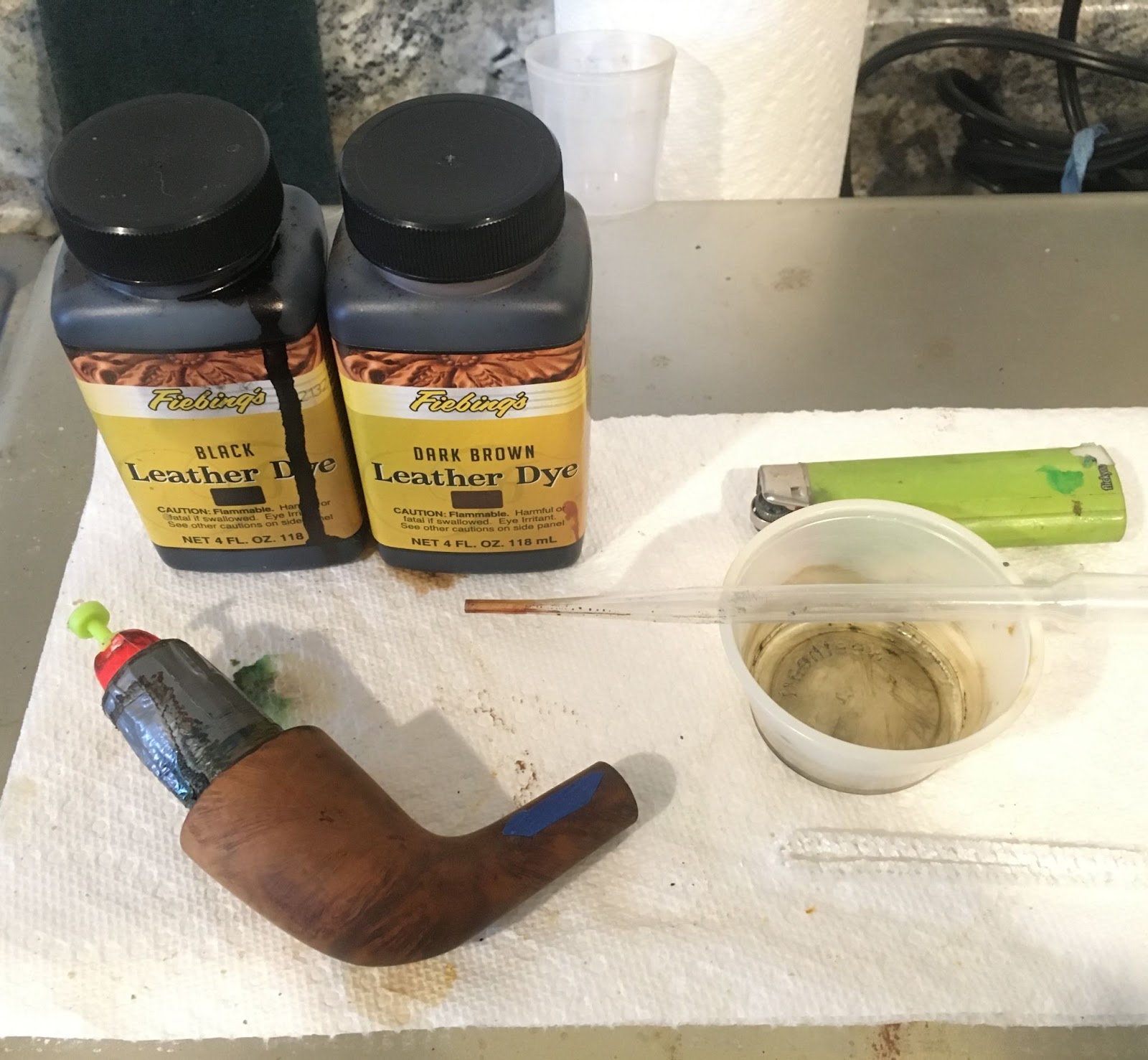

Next the interior of the stem was cleaned using bristle pipe cleaners dipped in 95% ethyl alcohol. The surface of the stem was lightly sanded with a 400 grit sanding sponge. After the sanding the stem was coated in mineral oil and set aside to absorb some of the oil.

I then turned my attention to cleaning the airway of the shank. I used cotton swabs dipped in alcohol to scrub the mortise, then the dental scraper to scrape the tar and yuck (yuck is the technical term for smoking residue and tar) from the shank as deeply as I could reach. The yuck that was removed was dry and crumbly even after the dawn dish soap and the alcohol cotton swab scrubbings.

I poured 5 ml of 95% ethyl alcohol into the bowl and allowed it to flow into the airway. I used a nylon shank brush to scrub the airway with the alcohol. The alcohol was then poured into a medicine cup. The color was dark but I could still see through it. The scrub brush was thickly caked with yuck.

More scraping and using alcohol dipped cotton swabs to clear the shank were used. Further alcohol-nylon shank brushings were done. Note the alcohol in the cup is much darker.

More of each of the above. I started going to the sink and applying Castille soap to the shank brush and scrubbing the airway with that. The soap was rinsed with warm water then alternated with the alcohol scrubbing.

Even after all that scrubbing with soap/alcohol.I was still scraping crumbly yuck from the airway.

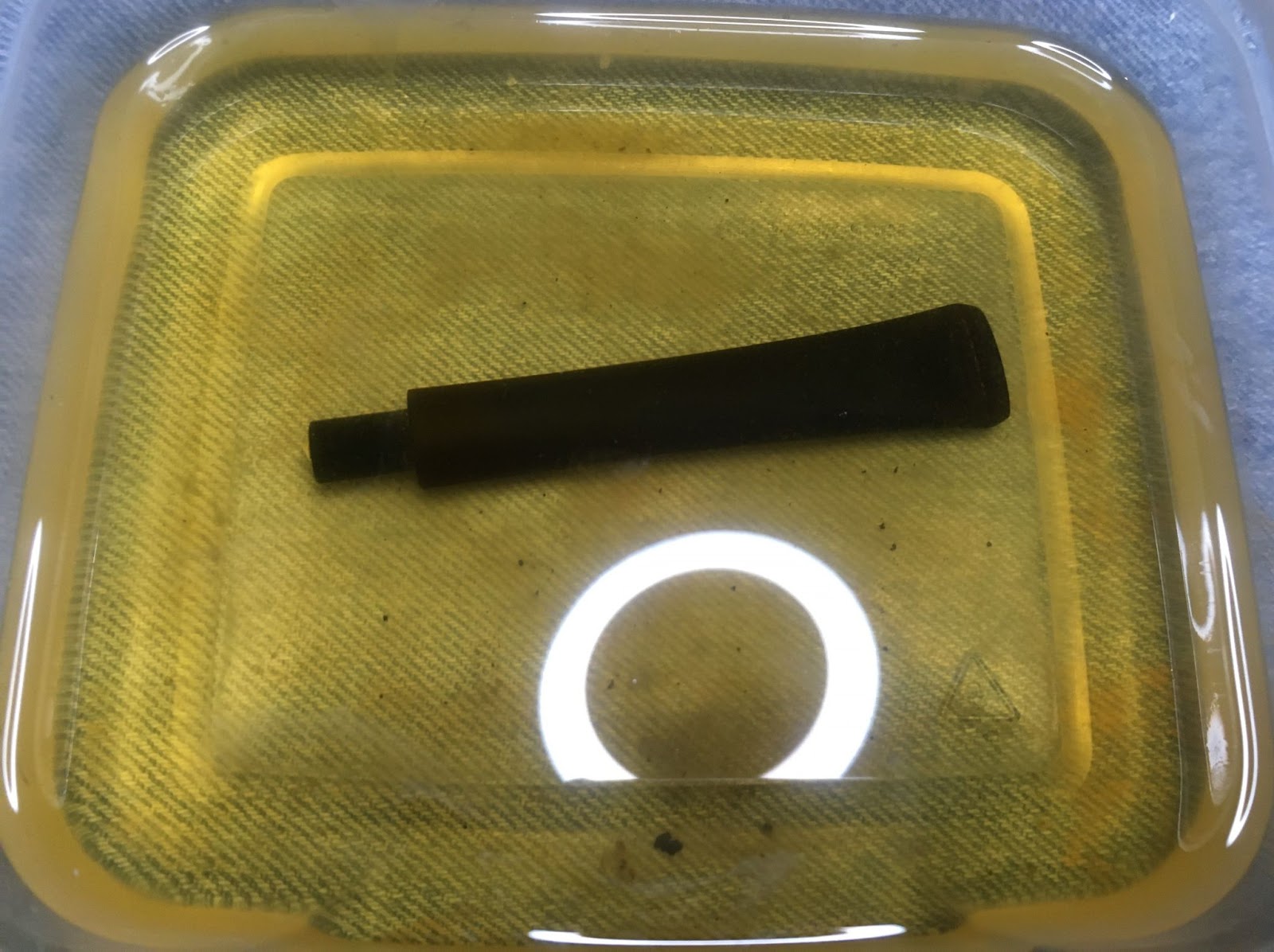

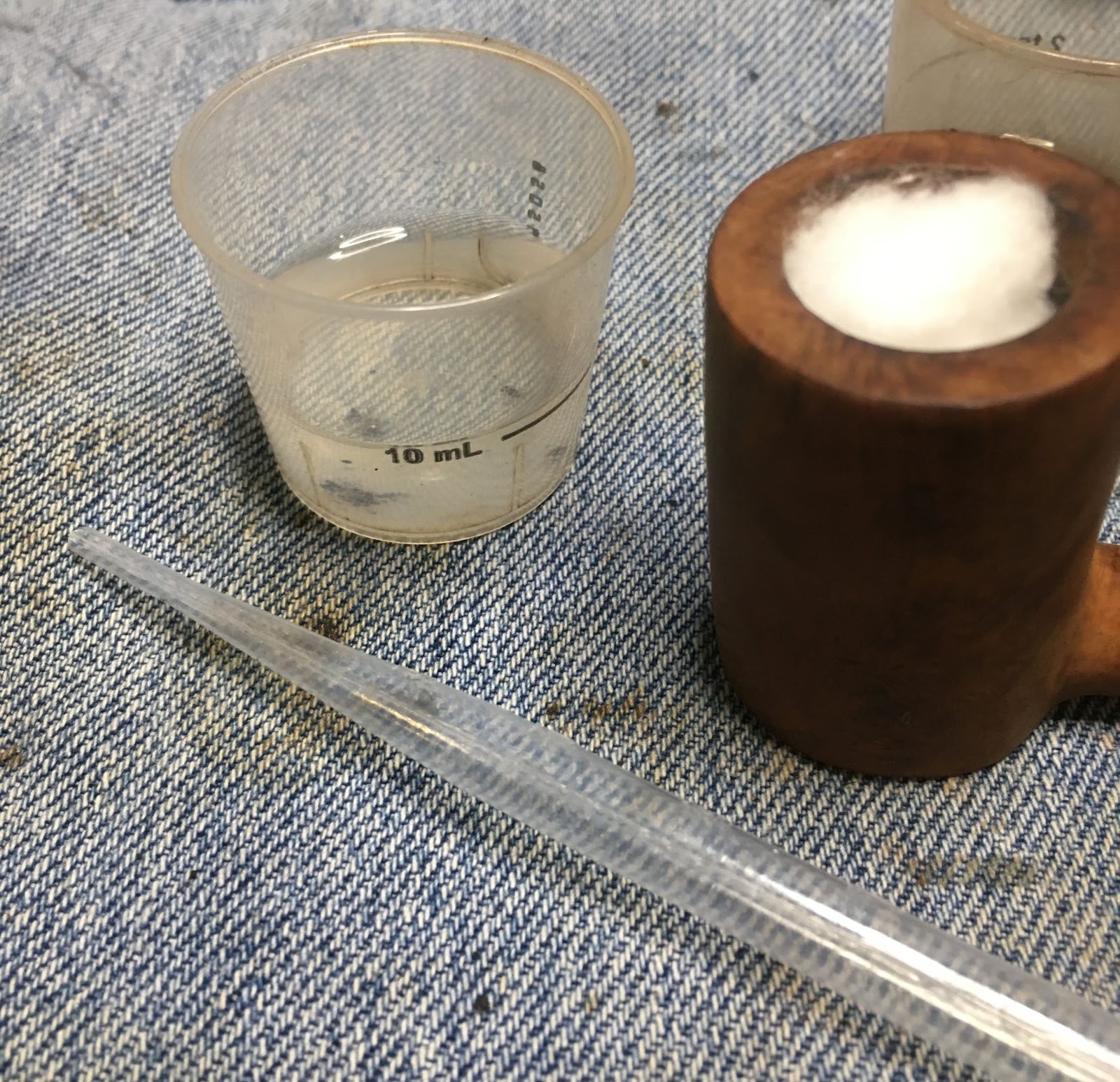

I was becoming a bit frustrated with the lack of progress. I knew it was progress but I had other things I needed to do. I decided to pack the bowl and shank with cotton and fill each with 95% ethyl alcohol. Hopefully the alcohol would dissolve the yuck and allow it to be absorbed by the cotton.

Below you can see the cotton pushed through from the mortise.

Shank view stuffed with cotton.

The bowl was stuffed with cotton. I figured that 10 ml of alcohol would suffice. I used a disposable pipette to soak the cotton.

I was close with my 10 ml prediction. Only about a ml remained in the medicine cup. The alcohol was allowed to soak for several hours.

While the alcohol did its dissolution magic, I returned my attention to the stem. I cut a piece of painters tape to cover the stem logo to protect it from scrubbing and sanding.

First I scrubbed the stem with Soft Scrub on a make-up pad. Surprisingly little oxidation came off.

The stem was then sanded with a series of sanding sponges from 1000-3500 grits. Between each sponge I would dip my finger in mineral oil, rub the oil onto the stem then wipe the stem with a paper towel.

After the final sponge I removed the tape and used a series of mich-mesh pads from 4000-12000 grit to polish the stem. Between each pad I applied a drop of Obsidian Oil, rubbed it onto the stem and wiped the stem with a paper towel.

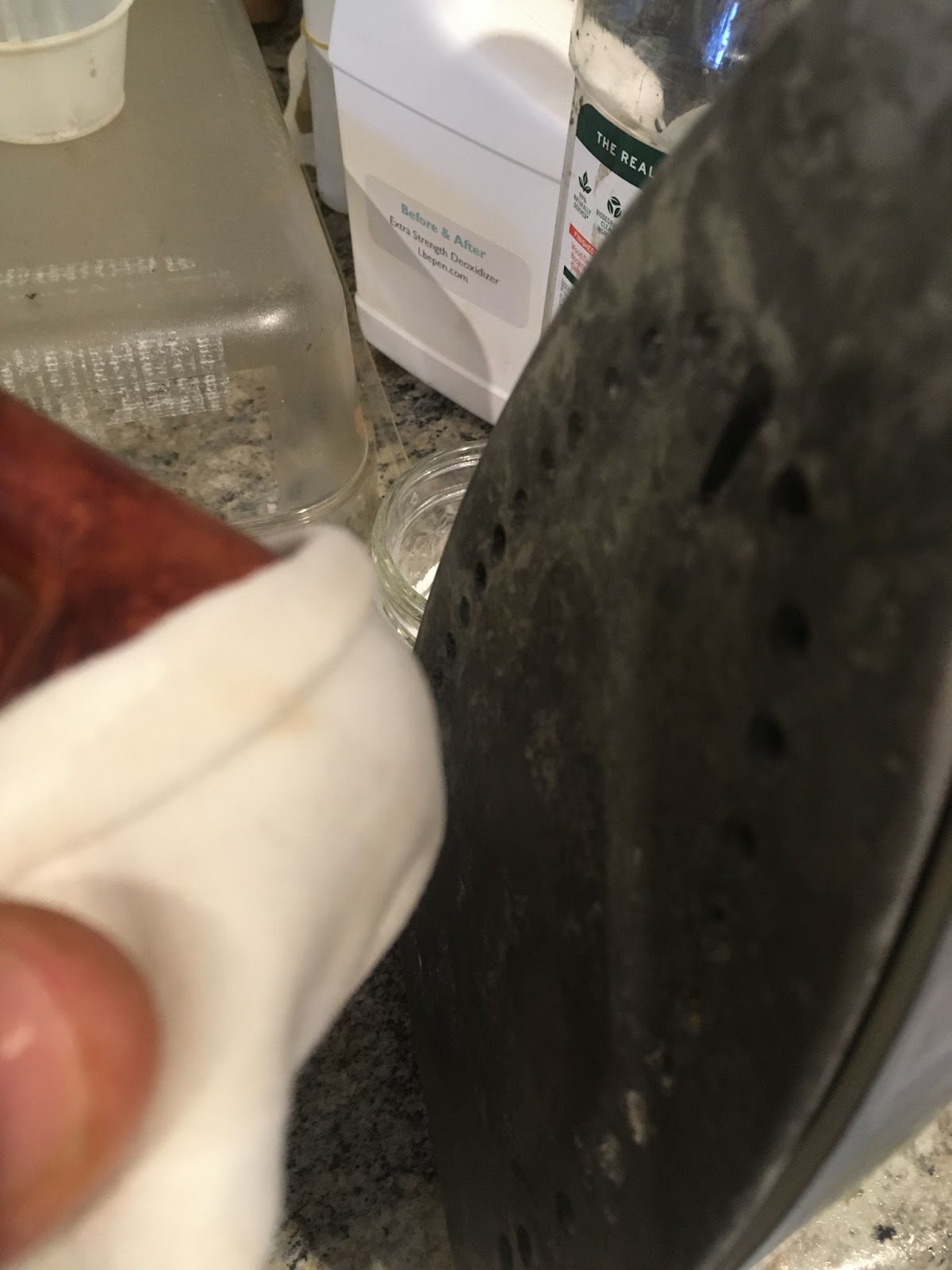

The stem was then polished with Before and After Fine Polish using a soft cotton cloth.

The fFine Polish was followed by Before and After Extra Fine Polish with a clean section of the same cloth.

Several hours later I removed the cotton which was now just slightly damp with alcohol as most of the alcohol had evaporated. The cotton was brown from absorbing the yuck as the alcohol evaporated.

Alcohol dipped cotton swabs and pipe cleaners finally returned with just a slight discoloration. A few more of each and the airway was finally clean.

The stummel was then sanded with a sequence of sanding sponges from 1000-3500. Between each sponge the stummel was wiped with a make-up pad moistened with alcohol.

After the sanding the stummel was polished with a series of micro-mesh pads from 4000-12000 grit. Between each pad the stummel was wiped with a make-up pad wetted with alcohol.

The stummel was then coated with Before and After Restoration Balm and allowed to sit for about an hour.

An hour later the Restoration Balm was wiped off the stummel using the inside terry cloth of an athletic sock.

The silver band was removed and the inside was cleaned with a cotton swab dipped in alcohol. This band was very thin, slightly thicker than heavy duty aluminum foil. Care was taken during the cleaning. The inside of the stem was then polished with Before and After Fine Polish on a cotton swab.

The end of the shank was then sanded with 600 grit sanding sponge to remove and smooth any remaining old glue. A bead of white all purpose glue was applied to the shank. The silver band was then slid into place. Excess glue was wiped off with the cotton swab and the surface cleaned again with alcohol. Once the glue had set up the silver was carefully buffed with white diamond abrasive on the buffer. The whole pipe then received several coats of carnauba wax with the buffer as well.

That was a personal record for me. The AOC Poker was the oldest pipe that I had ever restored. I am very pleased with how well the restoration turned out. The briar grain is beautiful; the old stain was preserved and not modified. The stamps indicating the pipe’s heritage were also preserved intact. The vulcanite cleaned up well and was returned to a lovely high gloss black. It was sad that the stamps on the silver band did not fare as well in their battle against time, wear and oxidation. Fortunately the date letter was legible. I would like to think that 150 years from now someone will rediscover this old poker and really have an old pipe to restore.

The dimensions of this Adolphe Oppenheimer Company (A.O.C.) Poker are:

- Length: 4.95 in./ 125.73 mm.

- Weight: 0.94 oz./ 27.00 g.

- Bowl Height: 1.71 in./ 43.43 mm.

- Chamber Depth: 1.50 in./ 38.10 mm.

- Chamber Diameter: 0.79 in./ 20.01mm.

- Outside Diameter: 1.17 in./ 29.72 mm.

I do hope that you have found something here useful to your own pipe care, maintenance or restorations. If you like this sort of thing, please click the like and subscribe buttons. Thank you for reading the ramblings of an old pipe lover.

Below are some photos of the finished A.O.C Poker.