Photographed and Written by

John M. Young

In all honesty, this is hardly a restoration. It is more of a cleaning and polishing. The pipe had never been fired. Why someone would do that is beyond me but after the last restoration I appreciate something that is more like pushing the easy button. I am not really sure when this pipe arrived other than it was at least a year ago. My record keeping started out very good when I began restoring pipes then went downhill quickly. Below are some photos of the Brigham billiard prior to starting work.

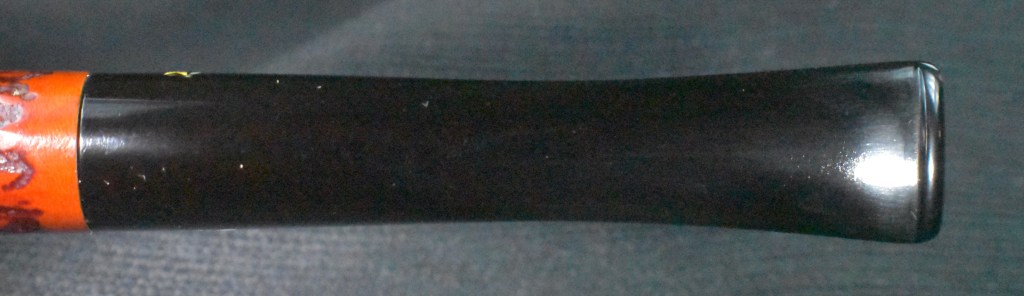

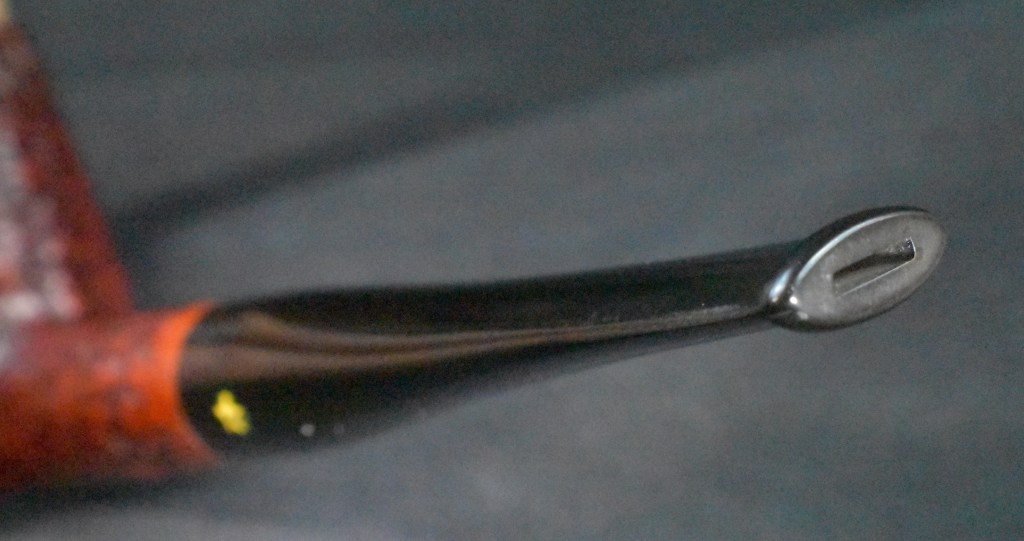

I am sure you noticed that the stem was not completely seated in the above photos. That is because it wouldn’t press into place without excessive force. The aluminum tenon was oxidized and I thought it best not to force it. The only other issue was the slight oxidation of the stem which made it look rather dull. Those were the only real things this pipe needed; aluminum polishing/oxidation removal and a stem polishing. Yay!

Background

Back on August 7, 2025 I wrote about a Brigham 202 Billiard with a dental bit. It is linked for those interested in that restoration. Anyway, I discussed The ultimate guide to Brigham pipes, a book by Charles Lemon. Here is a quote from that blog:

“The ultimate source of information on Brigham pipes is Charles Lemon, the author of Brigham Pipes – A Century of Canadian Briar. This wonderful book is available from Mr. Lemon on his website, Books, or from smokingpipes.com (Brigham Pipes – A Century of Canadian Briar | Smokingpipes) if you need to increase the total of your purchase to get the ever popular free shipping, and other various sources. I am unsure about Canadian immigration rules but I think this book should be required reading for prospective immigrants to Canada, especially if they are pipe smokers. ” (A Brigham 202 Billiard Restoration – NebraskaPeteGeek)

I once again found myself rereading Mr. Lemon’s work. My mind is far better at relearning than it is at remembering, Though I admit to being able to find the information much faster this time. The 1990s to early 2000s brought unique challenges and opportunities to Brigham. According to Charles Lemon, “ The company rounded the decade with two major introductions. The first, in response to demand for a lower-priced pipe, was the Italian-made Brigham System Pipe”, the first Brigham pipe made completely outside of Canada. The second and more far-reaching change was the development of the composite tenon, still in use today.” (Lemon, Charles. Brigham Pipe – A Century of Canadian Briar. Copywell, Woodbridge ON. Second Printing, October 2023. Page p. 51). So this dates the Brigham System pipe to the late 1990s. The next page narrows the latest possible production date to 2001.

Again referring to Lemon, “In all, Brigham tested ten different composite formulas before landing on a material that was less expensive than aluminum, strong, lightweight and tolerant of high heat levels. The new composite tenons generated quite a stir among Canadian pipe smokers when introduced in 2001, but the benefits, especially the much lower risk of a cracked shank, outweighed the initial resistance from Brigham pipe fans” (Lemon, p.52). One other dating quote from Mr. Lemon is in regards to the stem logo:

“”Brigham System” Pipes (late 1990s to early 2000s) were the first Brigham pipes made entirely in Italy. These were entry-level pipes available in 12 shape sand marked first with a yellow star on the stem, which later changed after 2001 to a maple leaf.” (Lemon, p. 55)

Since this pipe is clearly stamped as a Brigham System with a country of manufacture (COM) of Italy, a yellow star stem logo and an aluminum tenon it must have been made in the late 1990s to 2001.

The Restoration

From the photo table to the workbench, a scenic journey of about 15 feet, the pipe made it without incident.

I chose to work on the oxidized tenon first.

Using 0000 steel wool the oxidized aluminum was cleaned up and polished.

The mortise showed signs of some oxidized aluminum residue within.

I used a .22 caliber rifle brass bore brush to clean the mortise.

The shank was then cleaned with cotton swabs dipped in 95% isopropyl alcohol.

Once the mortise and tenon were cleaned up the two joined as they should.

I wanted to revitalize the stem with some buffing. I did not want to affect the finish on the shank, so I taped the end of the shank with masking tape.

Being the lazy bum that I am, I didn’t replace the buffing wheel and just used the white wheel and white buffing compound on the stem.

The yellow painted stem logo did take a slight beating from the buffing. I used some Pale Saffron acrylic modeling paint to refresh the logo. This color was a nearly perfect match to the original color. The acrylic paint was allowed to dry for a few minutes.

The excess paint was removed using micro-mesh pads. These were fine enough that the finish from the buffing was not noticeable.

The stem then received several coats of carnauba wax at the buffer. The stummel also was waxed with carnauba but very lightly as I did not want to fill the rustications with wax deposits.

The final step was to hand buff the pipe with a microfiber polish cloth.

This Brigham System pipe is one of the last Brighams made using the aluminum tenon. With its traditional internals and a very traditional billiard shape it is a very well balanced pipe with great hand feel. The texture does not show any real briar grain and the dye is rather artificial in appearance; it would certainly make an excellent working pipe for those projects in the yard or garage. I have had experience with the Brigham maple inserts and found that they do remove liquids and tar from the smoke effectively. The stem of this pipe polished-up very nickel and overall it looks like a brand new pipe. Which, never having been smoked, it really is. The dimensions of this Brigham System are:

Length: 5.95 in./ 151.13 mm.

Weight: 1.42 oz./ 40.26 g.

Bowl Height: 1.85 in./ 46.99 mm.

Chamber Depth: 1.66 in./ 42.16 mm.

Chamber Diameter: 0.84 in./ 21.34 mm.

Outside Diameter: 1.44 in./ 36.58 mm.

I do hope that you have found something here useful to your own pipe care, maintenance or restorations. If you like this sort of thing, please click the like and subscribe buttons. Thank you for reading the ramblings of an old pipe lover.

Below are some photos of the finished Brigham System Billiard.