Photographed and written by

John M. Young

I am only speaking for myself here as your results may vary but, I have found that alcohol consumption fails to make my decisions or their results better. I think that may have been the case with this lovely little Larsen as well. When I first got the pipe I was quite pleased with its appearance. Closer examination soon revealed a layer of Scotch tape around the tenon. “Hmm, that is not normal”, I thought. I then carefully removed and examined the tape and tenon. I immediately thought that a previous steward had broken or cracked the tenon but all was well there. Another “Hmm”. The shank was then examined. All I could think is; “What?”, “Why?” and “Huh?” Yeah, I ran out of “W” words. The mortise appeared to have two extra attempted drill holes widening the mortise significantly thus requiring the thickening of the tenon with the Scotch tape. I envisioned a scene where the previous owner just finished off a 750 ml bottle of some 40% ethyl alcohol and the movie The Driller Killer and decided to turn this Larsen into a Peterson System pipe. See the first sentence of this blog.

Regardless of the origin story of this Larsen and how it came to be, the pipe was certainly worthy of some restorative care. The pipe was stamped 85 over WØ LARSEN over MADE IN DENMARK perpendicular to the axis of the shank. Below are some photos of the Larsen when it arrived here.

The glaring repair to the mortise, shank and airway was the major task. The pipe otherwise looked to be in very good condition. There was some staining around the shank/stem joint probably from tars and condensation leaking around a bad mortise tenon fit. The acrylic stem had minimal wear.

Background

The first section of the quote below is from pipedia.org and is credited to “FinePies.Com.

“W.Ø. Larsen was one of the most famous tobacco shops in Copenhagen, with a beautiful store located on Copenhagen’s famous “Walking Street.” During the flowering of the Danish pipe in the 1960’s, they first began retailing pipes by such carvers as Sixten Ivarsson, Sven Knudsen, Poul Rasmussen, and Brakner.

Urged on by his store manager Svend Bang (S. Bang), the owner, Ole Larsen, decided to begin making pipes in the basement of the shop. He first hired Sven Knudsen as the pipe maker, who soon passed the job to his protégé Hans “Former” Nielsen. Larsen’s fortunes rose along with the rest of the Danish pipe business, and Former was soon managing a group of carvers in the old Larsen cigar factory. Among these were Teddy Knudsen, Tonni Nielsen, Jess Chonowitsch, Peter Hedegaard and others, who were responsible for the Select and Straight Grain series before they branched out on their own. After Former left to start Bentley pipes in Switzerland, his duties were taken over by Soren Refbjerg Rasmussen, while the Straight Grains were made by Teddy’s student Benni Jorgenson. As Ole’s health began to fail, the reins were taken over by his son Nils. Nils became convinced that the way for Larsen to prosper was by entering the low-end market, and acquired the Georg Jensen pipe factory to make an array of less expensive pipes. This turned out to be a fatal error, and Larsen was recently sold to Stanwell, who continue to produce so-called “Larsen” pipes in their huge factory. Thus ended an important part of Danish pipe history. Courtesy, FinePipes.com”(W.Ø. Larsen – Pipedia)

The next section also from pipedia.org

“From The History of Danish Pipes, by Jakob Groth

The workshop of W.Ø.Larsen

W.Ø.Larsen is Denmark’s oldest and probably most famous pipes and tobacco store, placed in the center of Copenhagen on the main pedestrian street, Stroget. If you visit Copenhagen and do a “pipe crawl” this store is a must. In the beginning of the 1960’s the store began to sell Danish hand-made pipes, especially those of Poul Rasmussen. This went very well and Poul Rasmussen could not keep up with the demand. W.Ø.Larsen, with their dynamic business manager Svend Bang (who later started his own pipe business), decided to establish their own workshop in rooms next to the store.

The first manager of the pipe workshop was Sven Knudsen, but he soon left to make pipes under his own name. The next manager was Hans Nielsen, also known as “Former” (named after the late British actor George Formby, whom he was said to resemble. Coincidentally, in Danish, “Former” means “shapes”). Under the management of Former the workshop grew and W.Ø.Larsen pipes became a prominent name abroad. Among the prominent pipemakers educated here were Else Larsen (Denmark’s first female pipemaker),Poul Ilsted, Ph. Vigen, Teddy Knudsen, Tonni Nielsen, and Peter Hedegaard.

Typical for the W.Ø.Larsen School were semi-classic shapes, meaning classic shapes, but with slight differences, often bring a little more full or round. The pipes often had lower center of gravity. A typical billard would have a bowl shaped more like a pear and the connection between the bowl and the shank would be clearly distinguished. Yellow and orange were colors more widely used for the finishes.”(W.Ø. Larsen – Pipedia)

Trying to get a date on this Larsen I turned to pipephil.eu. Here under W.Ø.Larsen I found the following images:

The uppermost image shows an identical stem logo to the pipe in hand. It unfortunately does not indicate the age or year of production. I returned to the pipedia.org site to look through the available Larsen catalogs. There are 3 catalogs on the site: A 1960-61, 1961-62 and a 1963. There was no mention of a shape 85 in any of the catalogs and the stem logo on my Larsen was not observed in any of the catalogs. One thing I found interesting is that the shape number 85 is completely absent.

(wo1.pdf (danishpipemakers.com))(red circle added by me). Now this is just me and my conjecturing brain, I think this Larsen is probably a Stanwell made Larsen. My reasoning is twofold: The Crown with LARSEN looks very modern and factory made

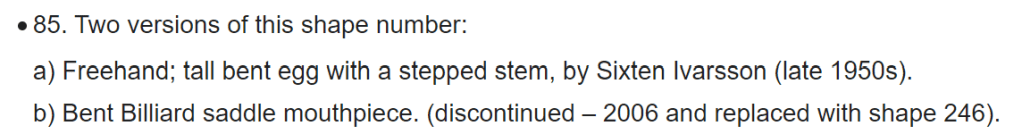

The 85 shape is a Stanwell shape. According to pipedia.org’s Stanwell shape number guide:

(https://pipedia.org/wiki/Stanwell_Shape_Numbers_and_Designers)

Numerous sources said that W.O. Larsen was “recently” acquired by Stanwell. I only found one source that defined “recently” – A Facebook entry by Pipes Pens and Much More, “Danish company W. O. Larsen started making pipes during 1950s and it was run by Ole W. O. Larsen (1920-2002), who created the Larsen Handmades. Ole, a reputable designer, was a member of the Academie Internationale de la Pipe and founded, in 1977, the company’s Tobacco Museum which, like the brand shop, closed in 2005. The brand became an associate of Georg Jensen in 1999, with the company having been run, since 1993, by Niels Larsen, the fifth generation of the family in business, until it was bought by Stanwell in 2003.” (https://www.facebook.com/pipespensandmore/posts/danish-company-w-o-larsen-started-making-pipes-during-1950s-and-it-was-run-by-ol/178742246947159/).

During the writing of this blog I sent fellow pipe restorer from Germany, Sascha Mertens a photo of this W.Ø.Larsen pipe. He did a bit of digging and came across a great article in a German blog by Ralf Dings. Mr. Dings, with his much more close to home knowledge discussed the demise of Larsen. The below is from his blog, W.Ö.LARSEN – EINE DÄNISCHE TABAKDYNASTIE and used with permission of the author.

“Niels W.Ö. was still young, but he used what he had learned to ensure that the Larsen name continued to do good business and maintain a brilliant reputation. His idea was to take over the GEORG JENSEN pipe factory to gain a foothold in the now popular segment of inexpensive pipes and thereby broaden Larsen’s range. Unfortunately, this plan turned out to be a fatal mistake, costing Niels W.Ö. so much money that he had to give up and sell to Stanwell. In 1997, what Wilhelm Öckenholt Larsen founded in 1864 came to an end.

Yes, there were and still are tobaccos and pipes that were and are marketed under the still good name Larsen. However, this marketing use has nothing to do with the tradition and the claim of the Larsen family, which filled several pages in the history of pipes. Anyone looking for a real Larsen pipe today, one from the Copenhagen era, should not have to worry about the hundred euro. However, they will receive a smoking device that represents the high-quality Danish classic as well as hardly any other brand could and can.” (https://rallis.blog/2018/09/17/w-oe-larsen-eine-daenische-tabakdynastie/?fbclid=IwY2xjawE4rR9leHRuA2FlbQIxMAABHS8u-DT3fmM6vPbjWxkKlijTt01-xZpdMw9HOUlmPIgewOpEj7t4EO9UTQ_aem_IAfzAO26BRAbx8sarJJUKA)

That would put this pipe’s date of manufacture after 1997 and before 2006, when the shape was discontinued by Stanwell. As for current production of W.O. Larsen pipes by Stanwell all I could find was the following: “Annually, W.O. Larsen features a Pipe Of The Year, designed and manufactured by Stanwell. These are distinctly Danish styles that are truly spectacular.” (https://www.pipesandcigars.com/category/shop-by-brand/wo-larsen/)

The Restoration

This restoration began like others, with a cleaned denim piece as a work surface.

The reaming tools included the PipNet with number 3 blades, Smokingpipes Low Country reading knife, General triangular scraper with tip ground off and a wood dowel wrapped with sandpaper.

The minimal cake was quickly removed with the PipNet.

I lightly scraped with the other scrapers and sanding returned the bowl to fresh briar. There was no indication of any damage to the tobacco chamber

The airway of the shank was next cleaned with cotton swabs dipped in 95% ethyl alcohol.

My plan was to fill the damaged airway with black J.B. Weld epoxy. To keep the epoxy from entering where I did not want it I planned to coat the contact surface of the tenon, a pipe cleaner (for the draft hole) and the end of a cotton swab. The cotton swab tip was to plug the “drilled reservoir” which a previous owner had drilled. I figured that the misguided bloke’s work should not be completely in vain. I will include another photo of the drill grooves I was planning on filling with epoxy, below. There was enough of the correct mortise remaining so, my thought was to fill the two drill paths to the right with epoxy, seat the greased tenon, clamp it to keep the tenon pressed to the left and let the epoxy cure. Hopefully the petroleum jelly would prevent the epoxy from adhering to the tenon. Once cured I could re-drill and smooth the airway.

I failed to photo the application of the epoxy as I was worried about it becoming too tacky. Below is the stem clamped in place.

A couple of hours later I removed the clamp and pulled the stem free. The Vaseline did what I hoped it would do, preventing the epoxy from adhering to the tenon. The airway remained clear of epoxy thanks to the Vaseline coated pipe cleaner and the cotton swab tip kept the epoxy from entering the reservoir. Success on everything so far. I allowed the epoxy to cure for a full two days.

I used a micrometer to measure the diameter of the tenon and discovered that a 5/16 in drill would allow a good fit of the tenon. I stepped the bit down to ¼ for the first re-drilling attempt. Then increased the bit size to the 5/16.

The re-drilling seemed successful and the tenon felt appropriately tight. Below you can see the epoxy patch. I was not happy with the seem around the patch but thought that black cyanoacrylate (CA, super glue) could be used to fill the slight gap to the patch.

The stummel was taken to the sink for a scrub with undiluted Murphy Oil Soap and a nylon scrub brush. The soap was rinsed with warm water and the stummel dried with a cotton hand towel.

Returning to the workbench I wiped the stummel with 95% ethyl alcohol on a make-up pad. A little bit of black stain came off onto the pad.

The scrubbing did little to remove the tar stains around the end of the shank.

I have successfully used oxalic acid to bleach briar previously. I thought that the technique might work here.

I applied the oxalic acid solution with a cotton swab to the unstained shank and set it aside to see if it would lighten the tar stains..

In the meantime I cleaned the pipe stem using 95% ethyl alcohol and bristle pipe cleaners.

A few minutes later I saw a marked lightening of the stained areas. Not completely removed but far better than they were.

I taped off the stem with painters tape to protect it during sanding of the shank and taped over the stamps to preserve them as well.

The shank was sanded with 1000-3500 grit sanding sponges.

At this point I used the black CA to fill the gap between the epoxy patch and the briar shank. I worked fairly well and was lightly sanded using the topping board and 400 sandpaper. There remained a very slight seem or gap. I filled this with clear Thin CA applied with a fly tying bodkin and lightly sanded with a 1000 grit sanding sponge. To reestablish the counterbore of the portise I used a small wood sphere wrapped in 320 sandpaper followed by 400 sandpaper. This was done because I was too lazy to go upstairs and into the garage for a countersink bit.

The end of the shank was touch-up stained black with a Furniture Touch-up Stain marker.

The stem and stummel were reunited and micr0-meshed with the 4000-12000 pads. This polished up the brass accent nicely.

The stem then received a hand buffing with Before and After Fine Polish on a soft cotton cloth.

The Fine Polish was followed by the Before and After Extra Fine Polish with the same cloth.

I worked some Renaissance Micro-Crystalline Wax Polish into the sandblasted surface of the stummel with a baby toothbrush and hand buffed it with a microfiber polishing cloth.

The pipe was then taken to the buffer where the stem and shank end received several coats of carnauba wax with the buffer.

This restoration was a project that required a bit of improvisation. I had never read of another restorer rebuilding a mortise using epoxy. I am sure it has been done as I doubt I am a very original thinker. The results seem to have worked. I have not smoked this pipe and admit that the remedy has not been tested under fire, pun intended. Overall I am quite happy with how this pipe turned out. It is a lovely shape with a great finish. I am looking forward to smoking it and testing out the repair. If you would like to know how the repair holds up feel free to ask in the comments.

The dimensions of this W.Ø. Larsen 85 Bent Billiard are:

- Length: 5.71 in./ 145.03 mm.

- Weight: 2.03 oz./ 57.70g.

- Bowl Height: 2.09 in./ 53.09 mm.

- Chamber Depth: 1.60 in./ 40.64 mm.

- Chamber Diameter: 0.77 in./ 19.56 mm.

- Outside Diameter: 1.62 in./ 41.15 mm.

I do hope that you have found something here useful to your own pipe care, maintenance or restorations. If you like this sort of thing, please click the like and subscribe buttons. Thank you for reading the ramblings of an old pipe lover.

Below are some photos of the finished W.Ø. Larsen 85 Bent Billiard.