Photographed and written by

John M. Young

I have to admit that I had no idea that Barclay Rex was a high end members only pipe shop. Actually I had never heard of a pipe shop where you could only access the premises via a membership. Although the old American Express ads where they said “Membership has its privileges”,’ now means a lot more to me. The below is from Barclays (https://www.barclayrex.com/rex-club)

I guess the good news is that you can redeem your quarterly dues for baccy and drinks. I do wonder what an accessory is. I would ask but the answer would probably come with another fee. Dang, I am glad I live in Nebraska and far removed from such things.

Back to the topic at hand, this lovely Barclay Rex 357. I’m not sure what shape to call it and cannot find anything on Barclay Rex shapes online. It is shaped similar to prince but with a straight stem the bowl is very apple shaped but slightly squashed. The pipe was part of the estate lot that contained the Peterson Red Premier Meerschaum 406 Prince which was blogged about a couple of weeks ago. I linked it if you are interested in that one. The lot came from Hollywood, Florida. This Barclay Rex 357 wears the following stamps: BARCLAY REX on the left and LONDON, ENGLAND over 357 on the right. On the bottom towards the stem there is a D stamped on the shank. Here are some photos of the Barclay Rex upon arrival.

There you can see the D stamp on the bottom of the shank.

Overall the pipe looked to be in very good shape. The stem was badly oxidized but it was oxidized evenly and there was no severe tooth chatter. The stain was brilliant and I wanted to keep that as original as possible. The briar had what appeared to be a clear coat of some kind, which had to go. The stampings were clear and defined. Yes, there was a lava deposit on the rim and some tobacco leaves in the bowl but the tobacco chamber was pretty clean. This looked to be a non taxing relaxing restoration.

Background

As previously mentioned Barclay Rex is a pipe shop in New York City. I will let Barclay’s speak for themselves, the following is from their website..

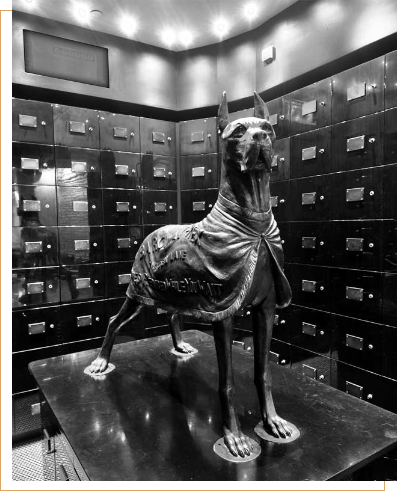

“REX THE FAITHFUL GREAT DANE

In 1910, Vincent Nastri, a pipe maker from Salerno, Italy, expanded his reach into the world of tobacco. A century later his vision is kept alive as Barclay Rex, a premiere Wall Street retail store. Originally nestled between Barclay and Church Streets, the store also borrowed inspiration from Nastri’s faithful Great Dane, called Rex, which led to the name Barclay Rex. In 1949, Barclay Rex moved to Maiden Lane, under the careful watch of Vincent Nastri and Vincent Nastri II.

For more than a half-century, father and son crafted pipes and expanded into other tobacco products. The torch would be handed down again as Vincent Nastri III stepped into the world that he had grown up in. At the turn of the millennium, Barclay Rex moved to a new location at 75 Broad Street, where it remained for 15 years.” (https://www.barclayrex.com/history)

Pipedia has an entry concerning Bracla’s as well. That article says this:

“Barclay-Rex, a downtown Manhattan tobacconist, was founded in 1910 by Vincent Nastri, a pipemaker from Salerno, Italy. The store was originally located at Barclay and Church Street, and the name was taken from that location and Nastri’s beloved Great Dane, Rex. The business is still run by Vincent Nastri, III and owned by Vincent Nastri, Jr.. They have several locations in New York City. The store has carried pipes from all fine makers, and the Barclay-Rex line of pipes is also much sought after, in that pipes were made in a range from the very inexpensive into the several hundreds of dollars. The pipes were, at least into the 1960’s, made of Algerian briar.

In addition to pipes made by Mr. Nastri over the years, Mr. Nastri, III, has been quoted as stating that a pipemaker just leaving Dunhill made pipes with a small off-white dot on the stem for a time for the shop. As was discovered by Steve Laug of Reborn Pipes, they were evidently made by a pipemaker whose initials were HGP, and stamped on the pipe as such. These pipes were made for a single run only, and then never made again.

While purportedly the initials of a pipe maker under the employ of Barclay-Rex, the initials “HGP” also appear in advertising for the Barclay Pipe Shop as early as 1920; the “HGP” initials evidently formed part of a trademark (see advertising below; The Pauw Wow, St. Peter’s College NJ 1935-left, and The Nation 1921-right) that was featured on pipes and (perhaps later) tobacco. If one accepts that Dunhill began manufacturing its pipes in earnest “from start to finish” in 1920, a year by which the “HGP” trademark was already in use by the Barclay Pipe shop, the likelihood of “HGP” signifying the initials of a pipemaker formerly in the employ of Dunhill diminishes considerably.

In addition, Sasieni at least for a time made private label pipes stamped with the Barclay-Rex name, but with their own shapes and shape numbers.” (Barclay Rex – Pipedia)

What can be gleaned from this? Well, I surmise that Barclay Rex did make pipes at one point. They are also known to outsource the pipe making to other companies and stamp their name on other makers’ pipes. This was a common practice for retail pipe merchants. Sasieni was a known supplier. Sasieni doesn’t produce a shape 357. What about other large English pipe manufacturers? Comoy’s do produce a 359 which is,

(Comoy’s Shape Number Chart – Pipedia)

GBD does produce a shape 357 and according to their shape chart,

It fits the pipe very well. The only discrepancy is the ⅛ bend to the stem. This most likely straightened with age and/or with heat (GBD Shapes/Numbers – Pipedia). I will therefore be referring to this pipe as the Barclay 357 Prince from here on. Judging by the oxidation on the stem I can say that this pipe has likely been exposed to years of light, heat and well, years. It did come from Florida after all and was part of an estate cadre that included the previously mentioned Peterson meerschaum pipe which was dated with pretty good certainty to the late 1970-early 1980s. I think this pipe is also of that era.

The restoration

As usual this pipe received a clean denim piece. Or, I should say, “The workbench received a clean denim piece” to protect it from the carelessness of the narrator.

The oxidation on the stem was job one. I started by buffing it with 0000 steel wool.

The stem stem was placed into a bath with OxyClean and water.

The reaming tools were gathered.

The PipNet did most of the work with this job. I only had to employ the scrapers near the end. The tobacco chamber was sanded with 220 sandpaper wrapped around a wood dowel. The bare briar showed no signs of any heat damage.

The rim had a relatively thick layer of lava.

This was moistened with saliva and carefully scraped off with a sharp pocket knife.

The stummel then made its way to the sink. Here it was scrubbed with undiluted Murphy Oil Soap and a medium stiff toothbrush.

The Murphy scrub seemed to have removed what I thought was a clear coat finish. Hmm, water soluble finish? I highly doubted that but was happy to see the unfinished briar.

The rim cleaned up nicely as well with the scrubbing.

The stummel was then wiped with a make-up pad dipped in 95% ethyl alcohol to make sure that there was no finish nor wax remaining. There was some color on the pad. This was mostly due to remnant tars on the rim.

The shank airway was cleaned next. This was done with numerous bristol pipe cleaners, cotton swabs and several ml of ethyl alcohol.

The airway still had the scent of old tar and smoking residue. I decided to give the stummel an alcohol treatment by packing the bowl and shank with cotton, filling them with 95% ethyl alcohol and letting them sit overnight.

The cotton was saturated using a disposable pipette while positioning the stummel so the rim and the shank were at the same relative level

The stem was retrieved from the OxyClean bath. The color of the vulcanite was different than I was used to, more of a flat gray.

I started vigorously rubbing the stem with a make-up pad. A surprising amount of oxidized rubber came off the stem. This was just with a dry make-up pad.

I cleaned the stem with bristle pipe cleaners and more ethyl alcohol then lightly sanded the stem with a 400 grit sanding sponge. You can see where I wiped the dust from the sponge on the denim in the photo below.

The stem still showed a great deal of discoloration from oxidized rubber after the sanding. I thought that an overnight dip in the Before and After Deoxidizer solution was in order. I pushed a pipe cleaner into the tenon end of the stem as a hanger and submerged the stem into the solution.

Overnight unturned into 24 hours due to the birthday party for my youngest granddaughter. Happy birthday, Lael. The next evening the alcohol had mostly evaporated, drawing the tars from the briar and depositing them in the cotton.

The cotton was removed from the bowl and shank.

Upon drying out I could no longer smell the scent of old tar and smoking residue. I could see rim damage from about the 10:00-12:30 position on the photo below. This would have to be addressed with a light reshaping with sandpaper and topping the rim.

It is difficult to see in the photos but the outer edge was sanded around the rin and the rim topped using 320 sandpaper, sponges and the topping board (AKA sandpaper laid flat on the counter). Further sanding was done by repeating this with 400 grit.

The stamps were taped with painters tape for their protection. I like to use irregular cuts on the tape to avoid the boxy look that can sometimes result from rectangular pieces of tape.

The stem was lifted from the solution and allowed to drip the excess solution back into it’s jar. The high tech deoxidizer drip device was used for this process – patent pending.

The stem was then vigorously rubbed with a coarse cotton shop rag. The rough cotton helps to abrade some of the oxidized bubber as it absorbs the remaining solution.

After wiping away the solution and running a couple of pipe cleaners through the airway the stem was lightly oiled with mineral oil. It finally looked black.

The stem was then rubbed with several make-up pads with Soft Scrub applied to the pads. You can see a general lightening of the color on the pads as the oxidized material was removed leaving non oxidized vulcanite behind.

The stem and stummel were reunited for the sanding. I did not want to sand them apart as that can leave rounded edges at the joint where the stem meets the shank. Between each sponge I wiped the stummel with a make-up pad moistened with alcohol. The stem received a rubbing of mineral oil by fingertip and was wiped with a dry paper towel between sanding sponges. The tape was removed after the 2500 grit sanding sponge.

The final two sanding sponges, 3000 and 3500 were used without the tape covering the stamps. The between sponge wipes occurred as above.

The pipe was then worked with 4000-12000 micro-mesh pads. I again wiped the stummel with an alcohol wetted make-up pad . I used Obsidian Oil rather than mineral oil between the pad on the stem.

The pipe was then coated with Before and After Restoration Balm, stem and stummel. The Balm was allowed to sit for 30 minutes.

30 minutes later the excess Restoration Balm was wiped away using an inside out athletic sock.

The pipe looked stunning. I took it to the buffer and applied several coats of carnauba wax. Then took all the “finished” photos for the blog. When I was typing I realized that I had not given the Prince the final bend to the stem. DOH! I retrieved a couple of my favorite Princes for comparison.

I then heated the stem in the oven to 250 degrees Fahrenheit. With a gloved hand I carefully bent the stem. I cooled the stem in cold running water at the sink to set the bend. I then re-waxes at the buffer and photographed the real “finished” shots of the left and right.

I am very pleased with how this Barclay Rex 357 Prince turned out. I was able to keep the original stain and preserve it’s wonderful contrast. The stem cleaned up very well and the high gloss black of the vulcanite really accents the briar. The ghost of any smell or taste from previous use is completely gone. The bend to the stem looks and feels great. I am sure that this pipe will be a grand easy to enjoy a nice English blend of tobacco.

The dimensions of the Barclay Rex 357 Prince are:

Length: 6.20 in./ 157.48 mm.

Weight: 1.28 oz./ 36.40 g.

Bowl Height: 1.44 in./ 36.58 mm.

Chamber Depth: 1.23 in./ 31.24 mm.

Chamber Diameter: 0.79 in./ 20.07 mm.

Outside Diameter: 1.69 in./ 42.93 mm.

I do hope that you have found something here useful to your own pipe care, maintenance or restorations. If you like this sort of thing, please click the like and subscribe buttons. Thank you for reading the ramblings of an old pipe lover.

Below are some photos of the finished Barclay Rex 357 Prince.

The below photos were taken pre-bending of the stem.