Written and photographed by John M. Young

It has been said that I suffer from Peterson Pipe Acquisition Disorder (PPAD). Though not a painful affliction, except in a financial way, it can prove detrimental to one’s long term mental stability. I believe the early symptoms include a strange desire to only smoke Peterson pipes. As the disorder progresses afflicted individuals feel a compulsion to own each of the Peterson 300 series shapes. In its latter stages individuals can become obsessed with owning an example of every Peterson pipe ever produced. These poor souls have been known to have and hoard hundreds of Peterson pipes which they refer to as “a collection”.

Fortunately, for myself, I seem to be in an early stage of the disorder and only have mild symptoms. This stage is often referred to as being a “Pete Geek”. Some symptoms in PPAD include rambling conversations with patients repeating the terms 1896, patents, well, chimney and P-lip. Some patients have been known to speak poorly pronounced Gaelic phrases like “Sláinte”, “Dia duit” and “Póg mo thóin!” In my case, I can still see the beauty of other brands and lines of pipes and, so far at least, not fallen into true Obsessive Compulsive Peterson Pipe Acquisition Disorder (OCPPAD).

The subject of this blog is a Peterson Captain Pete. The pipe was purchased via an auction from eBay. Peterson pipes have a long and storied history which is rich and fascinating. I highly recommend the book The Peterson Pipe, by authors Mark Irwin and Gary Malmberg as well as a reading of pipedia.com’s Peterson pages. According to Mark Irwin and Gary Malmberg, the Captain Pete:

“This line’s name was derived from the nickname of Charles Peterson, known affectionately as “Captain Peterson.” The first issue, c. 1940-62, was in a smooth finish produced for Rogers Imports with a white stamped P inside C, or a circled P on the mouthpiece. CAPTAIN over PETE on shank, and a MADE IN IRELAND in a circle. English made versions show CAPTAIN over PETE on shank or “CAPTAIN PETERSON” and A PETERSON PRODUCT over MADE IN ENGLAND or LONDON MADE over ENGLAND. The second issue (1998-), features an XL bowl with Sherlock Holmes shapes and compact stems, in rustic or combination of smooth and rustic, with a nickel band between two narrow brass bands.” (Irwin and Malmberg p.295)

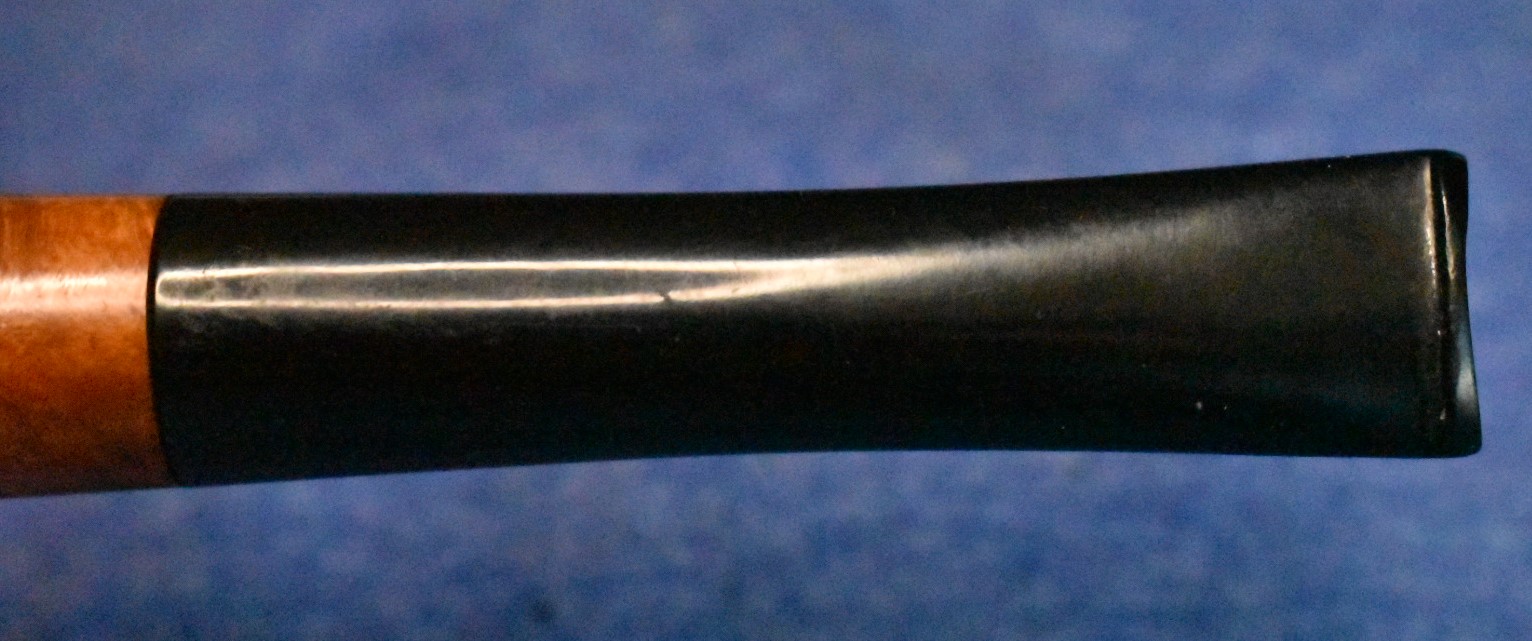

Photos of this Peterson Captain Pete when it arrived are below:

As you can see from the photos and by comparing them to the description of Irwin and Malberg, this is a first issue 1940-1962 pipe. The condition of the pipe is remarkable. I would judge that it was only smoked a handful of times. The lathe marks inside the tobacco chamber are visible though not shown in the photos. The condition of the stem and lower bowl interior are nearly factory fresh. When I first examined this pipe I thought the only work that I would need to do was minimal. It included; redoing the factory fills, 8 of them in total, reaming the slight cake of the tobacco chamber, fine polishing of the stem with a logo touch-up painting and a thorough cleaning of the airway.

I began with a look at the airway. It was remarkably clean, after swabbing the shank with a cotton swab dipped in 95% ethyl alcohol and a pipe cleaner

dipped in the same alcohol I only got a slight discoloring of the swab and cleaner. Though not spotless far cleaner than I would have expected from a pipe that was 60-80 years old. I suspected that someone had cleaned this pipe recently.

Next on the agenda were the fills. I do not enjoy replacing fill. Yes, I know it is a part of my pursuit and that the very nature that creates this wonderful wood, briar, would not have the characteristics that we require if it were to grow in more hospitable, less sandy environs. I still do not like fixing fills. “Quit whining, ya big baby.” “Oh good, you’re back. I was beginning to think I was alone.” “You’re not getting paid by the word so knock it off and fix the dang pits.”

I tried to photograph the pits and their factory fills. They were not badly done, just done in a factory. I know this pipe would never have made the cut at Dunhill’s due to the sand pits but a Peterson isn’t a Dunhill. Although

the finished goal is to have a finish that rivals a smooth Dunhill. Anyway, I began by picking out any old fill material that was soft enough to remove with a fly tying bodkin. There were 8 pits in all. I used the same bodkin to place a small drop of brown cyanoacrylate (CA, super glue) into a pit. I then used nitrile gloved fingers to take a pinch of briar dust and forcefully press the dust into the CA filled pit. The CA sets up near immediately with the briar dust so the motion of placing and pressing must be done quickly. Once one was filled I moved on to the next pit. Once all were filled I allowed them to sit and cure for a few minutes.

The beautiful Captain Pete now looked like a pox ridden mess. I remember learning the word carbuncle in High school English, Chaucer’s Canterbury Tales, perhaps. For some reason that word popped back into my mind.

The next task was to file the majority of the CA and briar dust “new fill” from the stummel while doing as little damage as possible to the stummel. Slow and steady are the keys to this. Now, a normal person can do this by feel. The CA is much harder than the briar and I am sure it feels significantly different than filing the briar. I cannot feel very much with my fingers. They are perpetually numb due to me having multiple sclerosis (MS). I have to use my eyes and ears to see and hear the file working rather than relying on a sense of touch. Since the file is covering the area being filed it is mostly by hearing that I do this. Once filed smoothish I turned to the sandpaper. I

used nothing coarser than 320 and this only with a very light touch. 400 was mainly used after which I went directly to the 1500 micro-mesh pad. Once sanded smooth I then checked for any slight spots where the briar dust had left tiny pores in the surface. When a tiny pore or depression was found I would lightly touch it with the bodkin touched with, not dipped in, brown CA. These very small spots of CA were then allowed to sit for 15 minutes to cure. After curing they were again smoothed using the 2400 micro-mesh pad.

I was now ready to start the micro-meshing of the whole stummel. I used painters tape to mask the stampings and reinserted the stem. I also taped over the stem logo. I used the 1500 and 1800 micro-mesh pads dry with a very light touch. After the pads I wiped the stummel off with a make-up removal pad moistened with 99% isopropyl alcohol. The stem did not require micro-meshing at this coarse of a grit so it was ignored. The 2400 micro-mesh pad was used on both the stummel and stem. The wiping of the stummel remained the same while the wiping of the stem between pads was done with a drop of Obsidian oil rubbed in by fingers followed by a wipe with a clean paper towel. This continued through the 3600 micro-mesh pad with the above mentioned wiping between pads.

Upon finishing with the 3600 micro-mesh pad and wipe I removed all of the painters tape. I then repainted the logo with acrylic model paint. This was allowed to dry for 10 minutes.

Once the paint had dried I began micro-meshing the stummel and stem with the 4000-12000 micro-mesh pads. There were a couple of spots inside the logo that needed to have paint scraped off. This was carefully done with the edge of a pocket knife. Between each of the micro-mesh pads the stummel and stem surfaces were wiped as before.

In examining the pipe after the micro-meshing I was not happy with the briar color. There were light areas where I had sanded during the filling of blemishes that did not match the stummel. I thought it would be best to lightly restrain the stummel using a diluted Fiebing’s Leather Dye.

I poured 5 ml of 95% ethyl alcohol into a medicine cup. I then used a clean soft pipe cleaner as an applicator. The pipe cleaner was dipped into the Light Brown Fiebing’s and stirred into the 5 ml of ethyl alcohol. THe dye was then applied to the surface of the stummel.

Several coats were applied to achieve complete coverage. The wet stummel was then flamed with a disposable lighter to set the dye. I then allowed the dye to dry for 15 minutes. After 15 minutes I began wiping the stummel with a make-up pads wetted with 95% ethyl alcohol. The pads removed much of the dye and blended the area very nicely.

Once all of the alcohol had evaporated I slathered the entire pipe with Before and After Restoration Balm. The balm was allied to sit and do its magic for 20 minutes.

I was definitely in the home stretch and the pipe was looking good. I wiped off the Restoration Balm with a soft cotton rag. I then polished the stem using Before and After Fine Polish applied with my finger and rubbed with a cotton rag followed by the Before and After Extra-Fine Polish.

The final step was to apply several coats of carnauba wax with the buffer. After buffing the pipe was hand buffed with a microfiber cloth and taken upstair for a photo session.

Overall I am very pleased with how well this Captain Pete turned out. I had always wanted to restore one of these and can now check it off the list. I do think that the previous owner had cleaned up this pipe and perhaps tried their hand at a restoration. It was remarkably clean, except for the need of a reaming, when I received it. One other thing that I noticed when working with the stem was the lack of any oxidation. For a pipe that is 60-80 years old there should be oxidation. I could tell that the stem had been buffed with noticeable buffing marks running perpendicular to the length of the stem. These were all removed during the micro-meshing. I do hope that you have found this informative and or entertaining. If you like this sort of thing please hit like and subscribe. Thank you very much for reading the ramblings of an old pipe lover.

*Irwin, Mark, and Gary Malmberg. The Peterson Pipe The Story of Kapp & Peterson. First Edition, second printing ed., Canada, Briar Books Press, 2018.

Below are some photos of the finished Peterson Captain Pete.

7 responses to “A Peterson Captain Pete Restoration”

[…] A Peterson Captain Pete Restoration […]

LikeLike

Well done, that one is almost a Supreme now!

LikeLike

Thank you. Heh, supremely pitted.

LikeLike

It does look much better than it did.

LikeLike

Thank you. Those fills were in a tough place.

LikeLike

[…] blogged about a Captain Pete back on December 31, 2023. You can see that restoration HERE, if you are interested. That was about the second month of my blogging. Anyway, I wrote […]

LikeLike

[…] on December 21, 2023 I wrote a blog about a Captain Peterson apple. That blog is linked for those interested. In that blog I said the following about the […]

LikeLike