Photographed and written by

John M. Young

As a little kid I used to sit with my father at his reloading bench while he reloaded rifle shells. It was my job to line up empty cases in straight little rows. Important work, to be sure. Later in life I too shared my father’s love of high power rifles, reloading and the study of reloading manuals. I remember shooting my first deer with a hand loaded 25-06 Remington. To this day, I can recall the load: 54 grains of 4831, Federal large rifle primer, 100 grain Nosler Boat Tail Ballisting Tip bullet. I cannot recall the muzzle velocity, like I used to but I still do have the Yugoslavian made Mauser rifle imported by Interarms. “What the heck does all that have to do with a du Pont Explosives promotional pipe?” you demand to know. Well, du Post explosives were not only the reason for the pipe but they also manufactured gun powder. A lot of it. Long before Dwight Eisenhower warned us against the influence of the military industrial complex du Pont was the largest US maker of black powder

Background

I have to admit that I was surprised that there was anything written about this pipe. The first place I looked was pipedia.org and low and behold, I got a hit. Below is the full text.

“du Pont Explosives pipes were given out as souvenir pipes by the Explosives Department of the du Pont Company between 1912 and 1933. (Source: Debra Hughes, Curator of Collections and Exhibits, Hagley Museum and Library, Wilmington, DE USA.) The original maker is unknown.

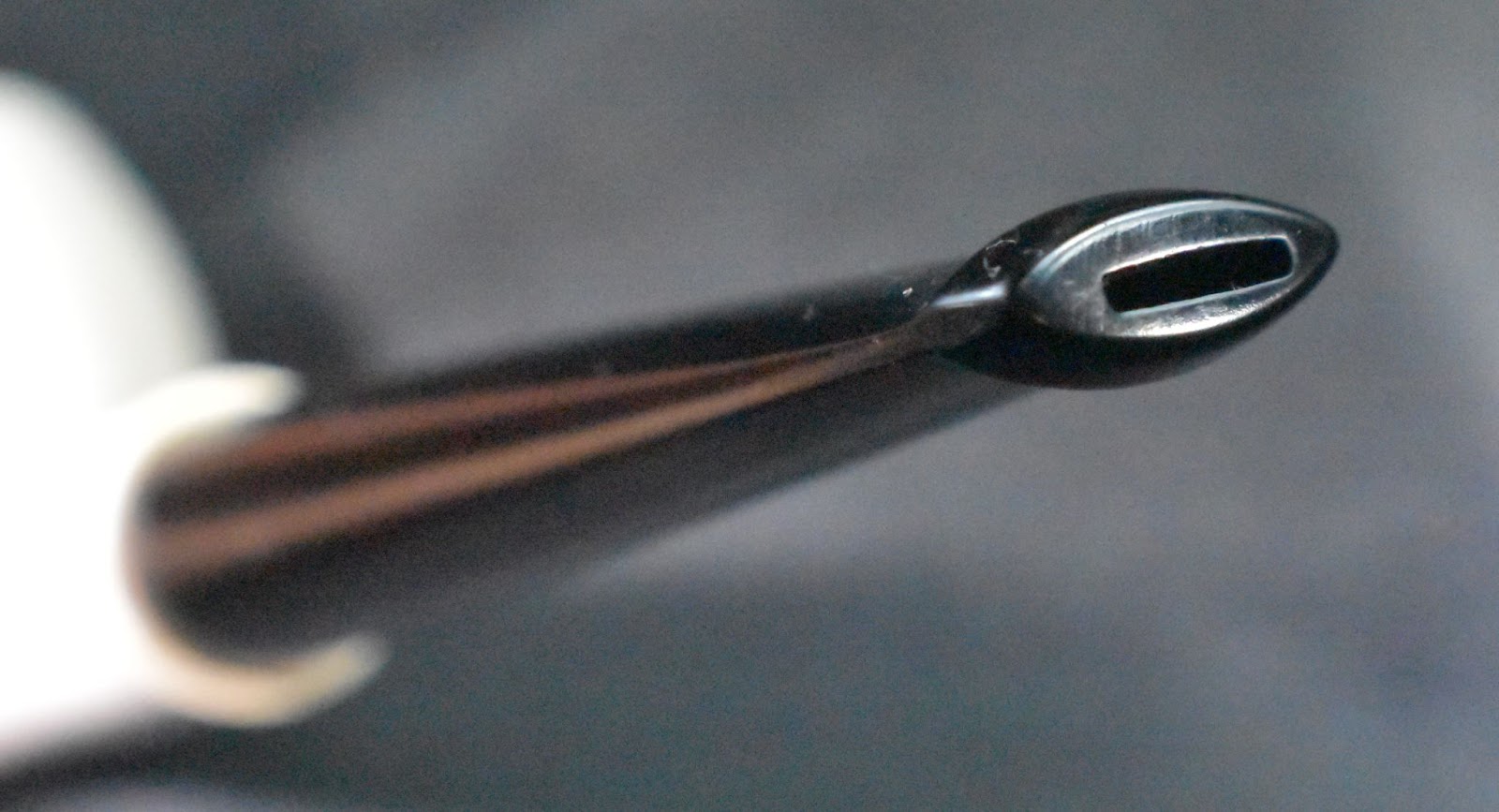

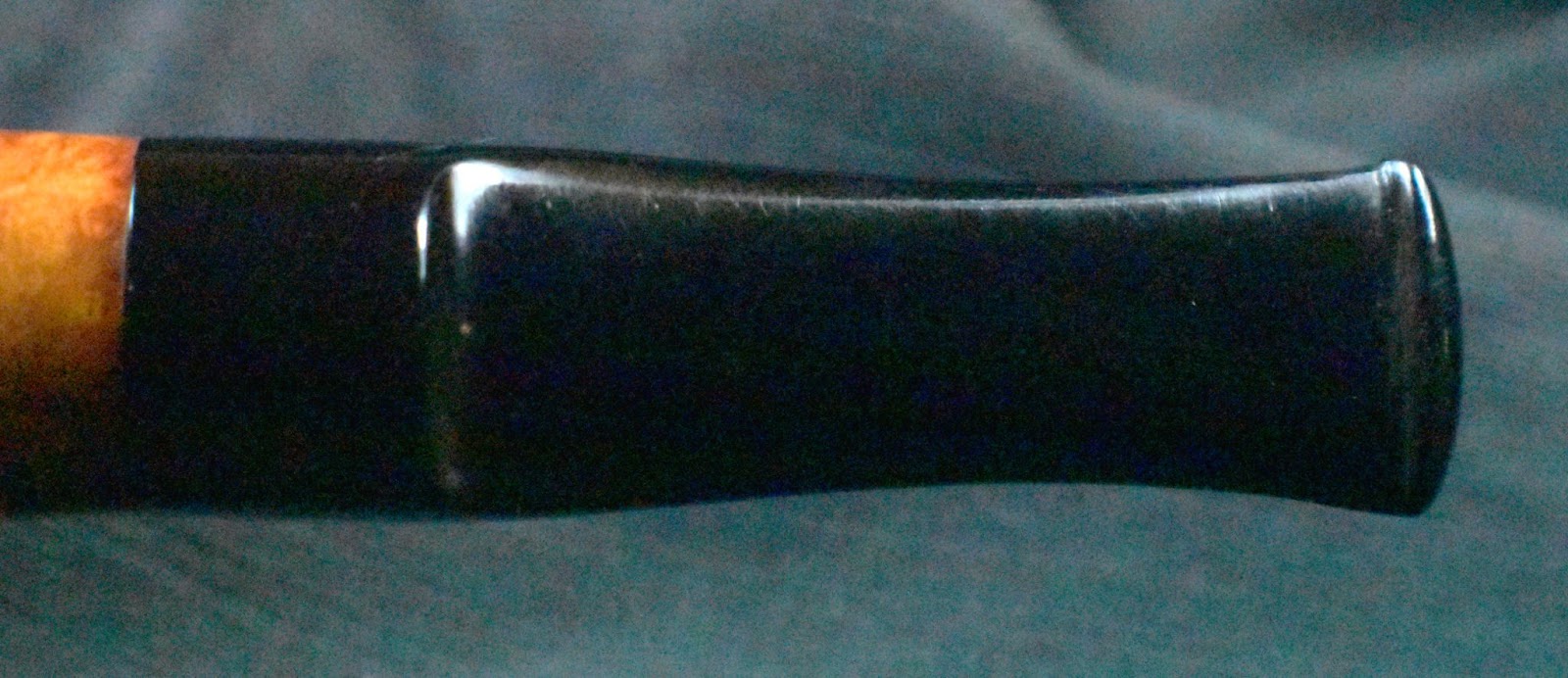

The shape is apparently intended to resemble an 18th or early 19th Century gunpowder barrel. Poker and bent shapes are represented. Some pipes may have ferrules. They are stamped with the duPont logo and “REG. US. PAT. OFF. EXPLOSIVES” on one side and “GENUINE FRENCH BRIAR” on the other side. Stems are vulcanite or similar material.”

Example du Pont Explosives pipe bowl-

Example gunpowder keg with extra bands to prevent staving

- An unsmoked example, courtesy Brian Robertson Collection

(DuPont Explosives promotional pipes – Pipedia)

Well, that pretty much sums up everything I wanted to know. That dated the pipe to 1912-33 and put the production in the USA, probably. I can’t imagine a foreign carver being too concerned with US patent registration. The 1912-1933 dates would precede the briar shortages of World War 2. I have not read anything about briar shortages caused by World War 1 but I am certain that they would have existed. One other thing I found interesting was the painting of the indentations of the stamp, as seen in the photos above. There was no sign of any remnant paint in the stamp on the pipe in hand. I was not sure how to or if to replicate this on the restored du Pont pipe.

The Restoration

Much to my chagrin, I worked on two pipes simultaneously. I normally do not like to do this as I inevitably forget steps or the photographing of steps, but my schedule has included a couple of fishing tournaments as of late. Priorities, priorities… Both pipes shared a denim piece on the workbench.

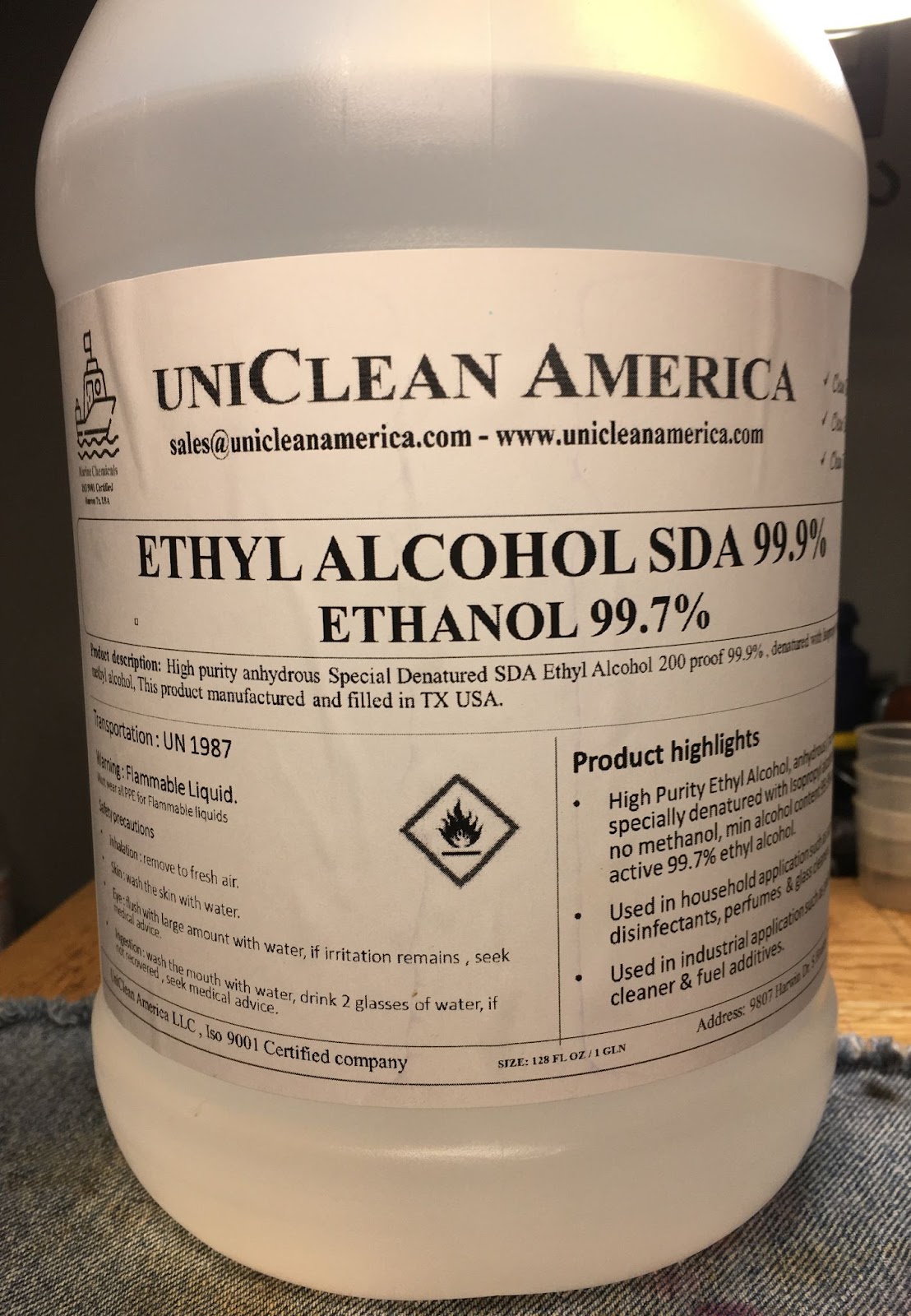

The first task was to prepare the stem for a bath in Briarville Pipe Stem Oxidation Remover. To do this I wanted the stem clean. I first tried my standard treatment of 99% ethyl alcohol on pipe cleaners. The stem started to feel slick in my fingers. The ethyl alcohol was dissolving the surface material on the stem. “Okay”, I thought and remembered the quote from the pipedia.org, “Stems are vulcanite or similar material” (DuPont Explosives promotional pipes – Pipedia). Hmm, I switched over to a 91% isopropyl alcohol thinking that the larger molecule would be less likely to act on the rubber. It worked and after several bristled pipe cleaners dipped in the 91% isopropyl alcohol the stem was clean.

Both stems were dropped into the bottle of Briarville Pipe Stem Oxidation Remover. I will refer to this as deox from here out.

I thought back to April, 2025 after Briarville gave me a bottle of their product to try. Usage had discolored it severely but it was still working. Sorry, I digress. The stems were to be left in deox overnight.

The ream team was assembled. The PipNet #2 and #3 blades were the proper size.

The PipNet did its job of removing the cake, admirably. The General triangular scraper was just used to clean up at the bottom of the chamber.

The reamed chamber looked good but the rim definitely needed some work.

The lava on the rim was softened with saliva. After a couple of minutes the lava was scraped with a sharp pocket knife.

The cleaning of the shank airway was done with 99% ethyl alcohol on a nylon shank brush, bristle pipe cleaners and numerous cotton swabs. A dental scraper was also used.

After the shank cleaning, I sanded the tobacco chamber with 320 grit sandpaper wrapped around a wood dowel. The bare briar showed no sign of heat damage. Below are photos showing the left and right chamber walls.

Next, the stummel was taken to the sink where it was scrubbed with undiluted Murphy Oil Soap and a nylon brush. The soap was rinsed with warm water and the stummel dried with a cotton hand towel.

I wiped the surface of the stummel with a make-up pad dipped in 99% ethyl alcohol. The pad showed some sign of remaining grime. I wiped it a couple more times to remove whatever the scrubbing missed.

I was not convinced that the airway was completely rid of the smoking residues. The pipe also still had an aroma of old aromatic tobacco. Though not unpleasant, I wanted to remove them. TO do this I packed the tobacco chamber, airway and shank with cotton.

The cotton was saturated with about 10 ml 99% ethyl alcohol applied with a disposable pipette. This was allowed to evaporate overnight.

The next day revealed that the alcohol had worked at dissolving the yuck (technical term for smoking residue) from the walls of the airway and deposited said yuck into the cotton.

The yuckified (the technical term for cotton soiled with dissolved smoking residue) cotton was removed.

I ran an alcohol dipped bristle pipe cleaner through the airway and scrubbed with a cotton swab also alcohol fortified. Both devices returned with little yuck. Triumph!

The inner and out rims of the bowl showed signs of abuse. I lightly topped the rim but refused to top it severely enough to remove all trace of the damage. That would have shortened the height of the bowl by nearly an 1/8th inch or 3 mm. Instead, I slightly beveled the inner and outer edges with a file and sandpaper.

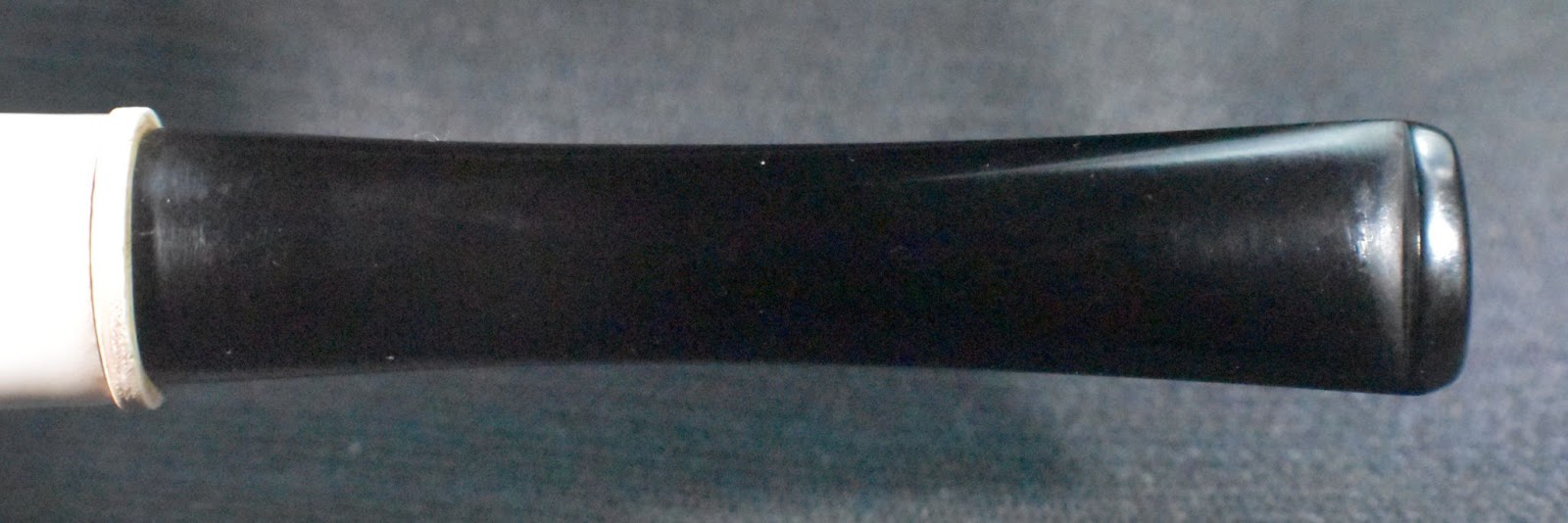

The stem was taken from deox and vigorously rubbed with a coarse shop rag. This removed a good deal of the oxidized material from the surface of the stem.

Below shows the pre-sanded but oiled stem and stummel.

I tried to paint the tooth dents on the stem with a soft flame lighter. This rarely makes a big difference but it’s fun to do.

The tooth chatter was filed with a small flat file and the edge of the button was slightly defined on both the top and bottom sides. These were also lightly sanded with a 320 sanding sponge.

Here is a great example of why I do not like to do two pipes simultaneously. I failed to document the application of the cyanoacrylate (CA, super glue) to fill in the deeper tooth dents. Rather, all you get to see is the filled and filed smooth result.

With the fills on the stem complete, I turned to the one big fill on the left rear of the stummel. The old fill material was picked out using a fly tying bodkin. This new fill would certainly leave a scar but it would be a smooth shiny scar.

I used a fine applicator tip on a bottle of Thin CA to apply a tiny bit of CA into the depressions. I then placed briar dust on top of the wet CA. The excess dust was brushed off. I topped the briar dust with additional Thin CA.

The new fill was sanded to see where additional CA and briar dust would be required. Oh yeah, the reason for the masking tape of the stamps was to protect them from my sanding.

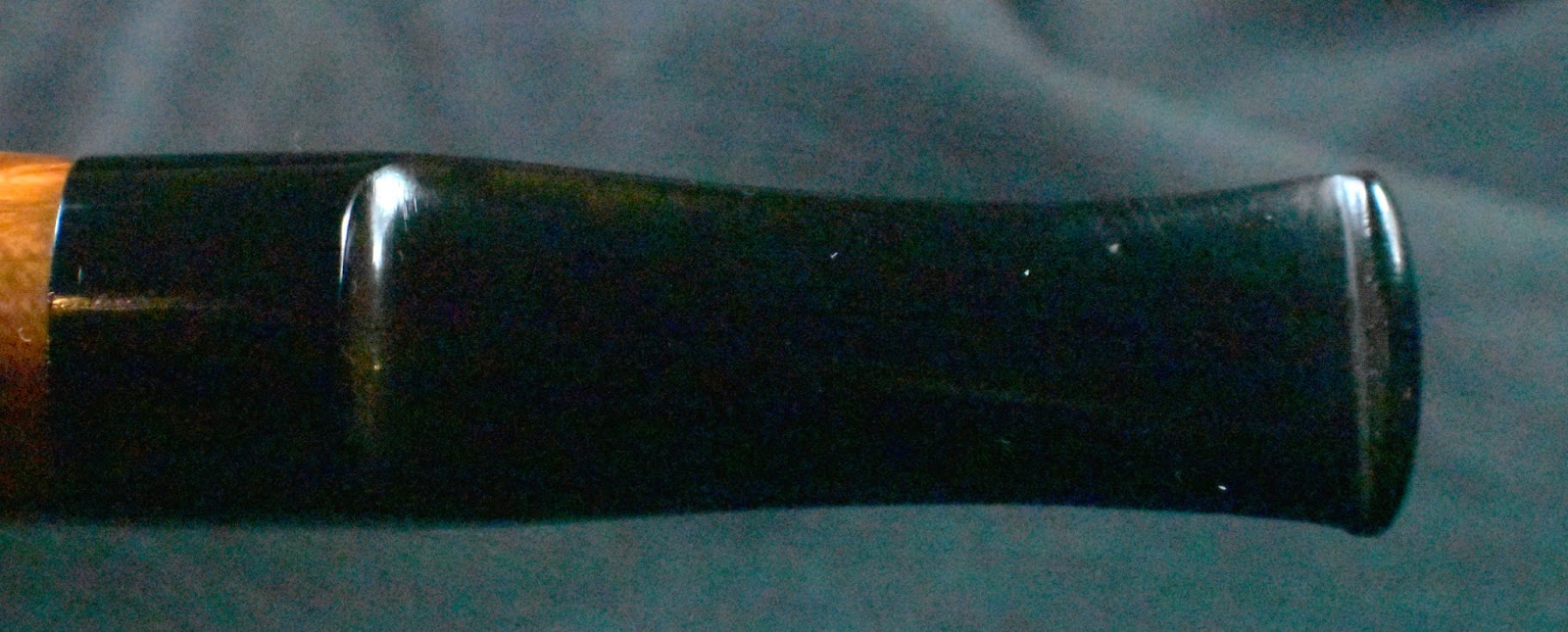

The stem and stummel were sanded simultaneously with a series of sanding sponges in grits 400-3500. Between sponges the stummel was wiped with a make-up pad wetted with alcohol while the stem was rubbed with mineral oil and wiped with a paper towel.

After the sanding the pipe was worked with micro-mesh pads 4000-12000. The wiping between pads was done as with the sanding sponges except the stem was oiled with Obsidian Oil.

The stummel was then coated with Before and After Restoration Balm and allowed to soak in that balmy goodness for 20 minutes.

The remaining Restoration Balm was wiped from the stummel with an inside out athletic sock.

The pipe then received several coats of carnauba wax applied with the buffer.

The final step was a hand buffing with a microfiber polishing cloth.

This du Pont pipe was a fun restoration. Not only did it allow me to reminisce about my father and reloading but also gave me the chance to work on a pipe that was probably 100 years old. This old gal is still quite pretty and the bent poker, that’s what I am calling it, shape is intriguing and fun. The briar grain is mostly concealed by the ring carvings of the “gun powder barrel” but the shank sides show lovely bird’s eyes. The hard rubber of the stem did polish-up nicely and provides a fine accent to the natural color of the briar. This historical sitting pipe will make its next owner a fine and historical tobacco enjoyment tool. The dimensions of this du Pont Explosives promotional pipe are:

Length: 4.70 in./ 119.38 mm.

Weight: 1.53 oz./ 43.36 g.

Bowl Height: 1.79 in./ 4.47 mm.

Chamber Depth: 1.58 in./ 40.13 mm.

Chamber Diameter: 0.80 in./ 20.32 mm.

Outside Diameter: 1.30 in./ 33.02 mm.

I do hope that you have found something here useful to your own pipe care, maintenance or restorations. If you like this sort of thing, please click the like and subscribe buttons. Thank you for reading the ramblings of an old pipe lover.

Below are some photos of the finished du Pont Explosives promotional pipe.