Photographed and written by

John M. Young

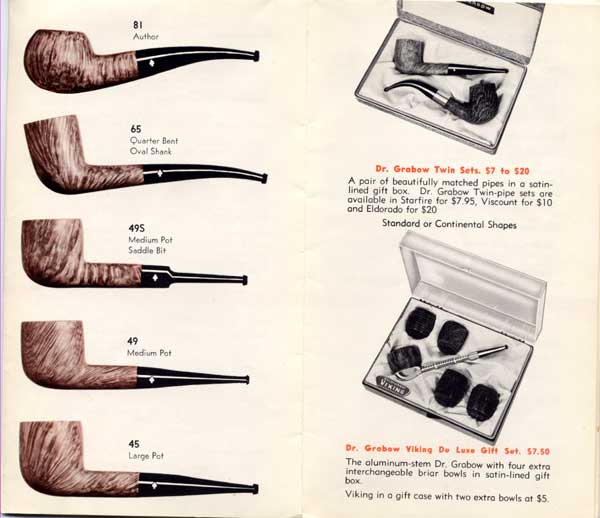

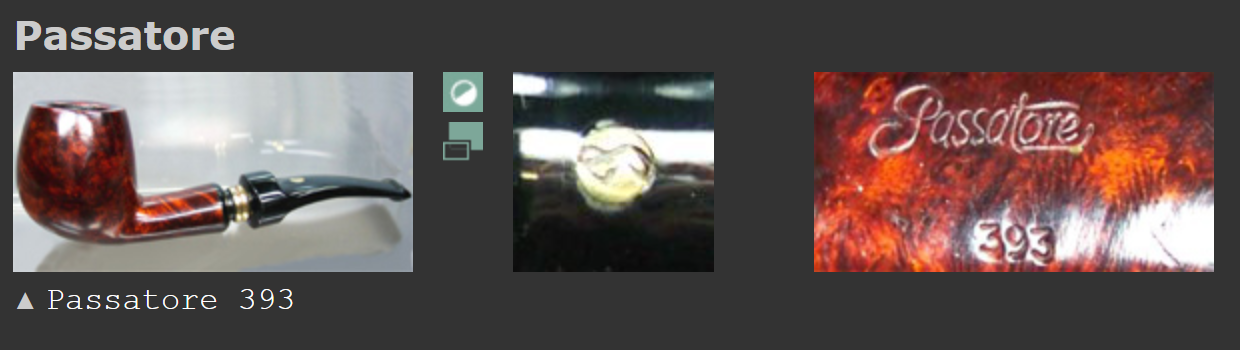

I have a Passatore here. Wait a minute, I am getting ahead of myself. Let me start with what I had in my hand. This pipe came to me from Greece as part of a 6 pipe estate lot. Previous blogs have discussed a Parker and a Savinelli that were part of the same lot. I linked their names to the respective blog posts if you are interested in reading about them. Here are some photos of the pipe upon its arrival before I knew what to even call this beauty.

I looked at the stampings on the pipe in hand and tried to decipher the weak stamp and ornate logo.

I was thinking the stamp looked like it started with a “J” and was first drawn towards Jeantet. All of the “J” Jeantet logos were very clearly a “J” and not ornate. I started scouring pipephil.eu logos. Not finding any matches with their single letter or circled letter logos was getting disheartening. I then clicked their “ornate spot” logo and found a match.

(http://www.pipephil.eu/logos/en/dots/rond-decore.html)

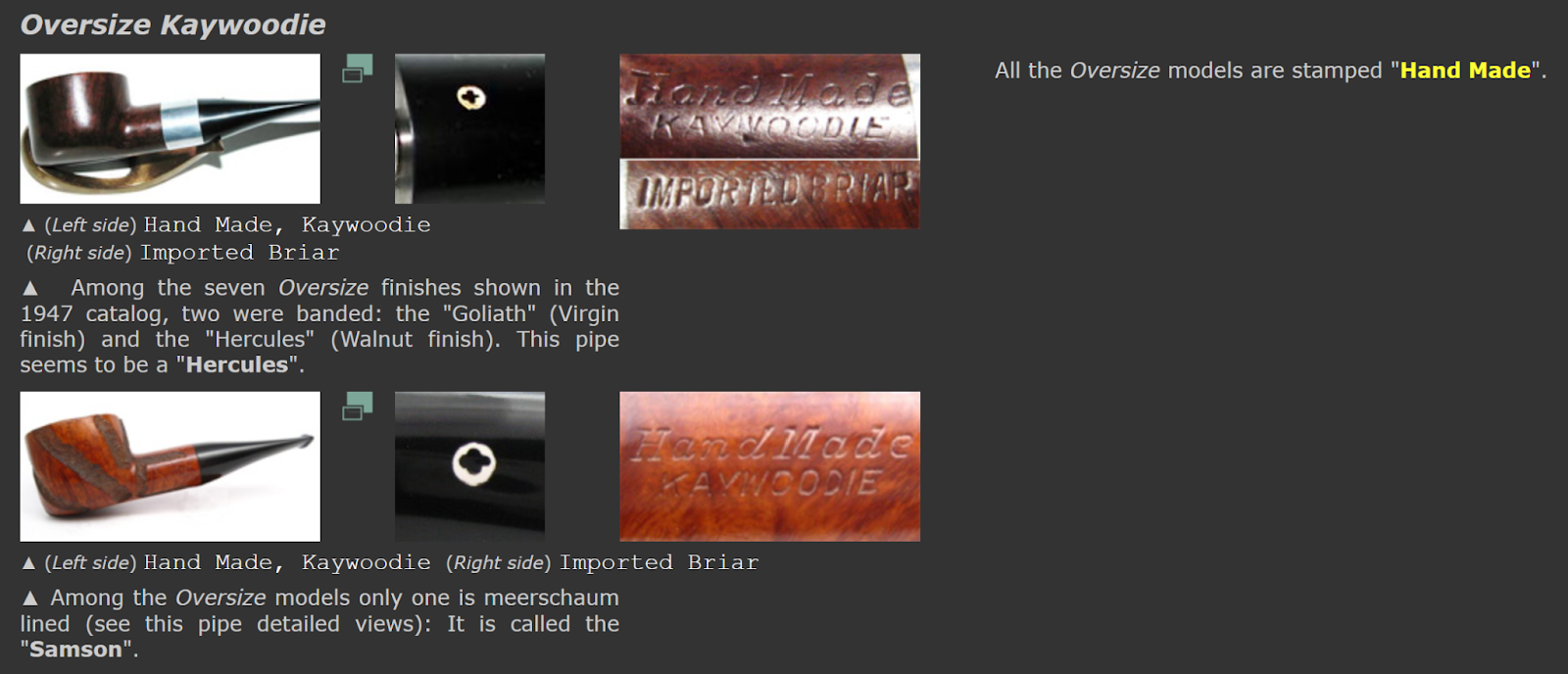

This was the entry on pipephil.eu which led me to the maker. Though the photo was not great it was definitely the same as the pipe in hand. This led me to Passatore.

What I was thinking was a “J” from the weak stamp and logo was a “P”. The 3 digit shape stamp, I assume it is a shape stamp, also was present on the Passatore in hand.

Passatore. That was a pipe maker that I had never heard of. Actually it was a word I wasn’t familiar with either. It sounded Italian so I started with that.

passatore (Italian)

Noun

passatore (masc.)

(https://www.wordsense.eu/passatore/)

That in itself is kind of fun, I think of it as, one’s pipe is a “guide” on how to live life – with relaxed and contemplative being key practices.

I struggled to find any substantial information about Passatore as a pipe brand. I reached out to Steve Laug, of rebornpipes.com, to see if he was familiar with the brand. He said that he had not restored one, which is saying something, but that he had received a Passatore box used to package a pipe sent to him from Budapest.

(Photo courtesy of Steve Laug)

Further internet searches led to a couple of European pipe shops that carried Passatore pipes:

https://www.haddockspipeshop.com/en/ This shop had 15 different Passatore models as well as an assortment of Passatore accessories like lighters, pipe tools and leather pouches.

https://www.german.us/en/pipe-holder/1006-passatore-splendida-oliva-ueipe-in-set-with-pipe-stand.html A second pipe shop that had a beautiful olive Passatore pipe with a unique pipe stand included.

All of my searching for historical information on Passatore was not leading me anywhere and I certainly do not need to go shopping for more pipes, even very pretty olive woods. I turned to restoring the Passatore that I had. Initial inspection revealed a pipe that needed some restoration to return it to glory or at least return it to proper working condition. The stem had come unglued to it’s brass accent bands and had deep tooth chatter on both surfaces, the rim was lava encrusted and probably darkened with char, the tobacco chamber had a respectable cake and there appeared to be two area where someone had attempted to glue cracks in the stummel. Both of these cracks looked superficial and not structural.

Cleaning the Stem

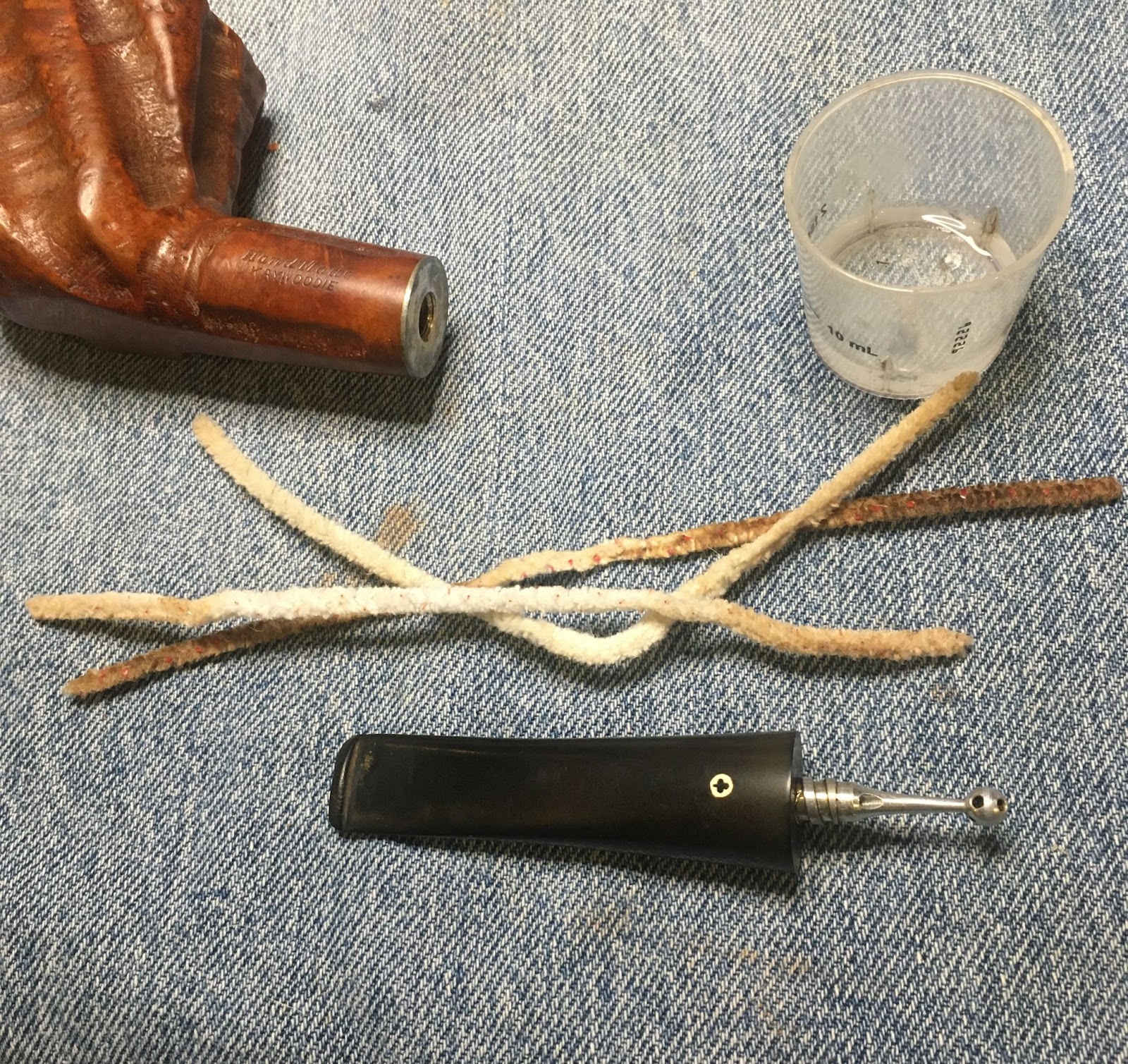

I started with a clean denim piece on the work surface. The parts of the stem made me

think of the old Wendy’s commercial “Parts is parts”. I’ll link to that for those wondering about my sanity or sense of humor. The first thing I did with the parts was to clean the existing glue from the surfaces to be reglued. This was done by softening the existing glue remnants with 95% ethyl alcohol and scraping with a sharp pocket knife. Removing the old glue was necessary to get a tight fit of the parts.

Before I reglued I wanted to clean the stem completely. It being apart made the cleaning much easier. Scraping with the brass rings and tenon would have been impossible.

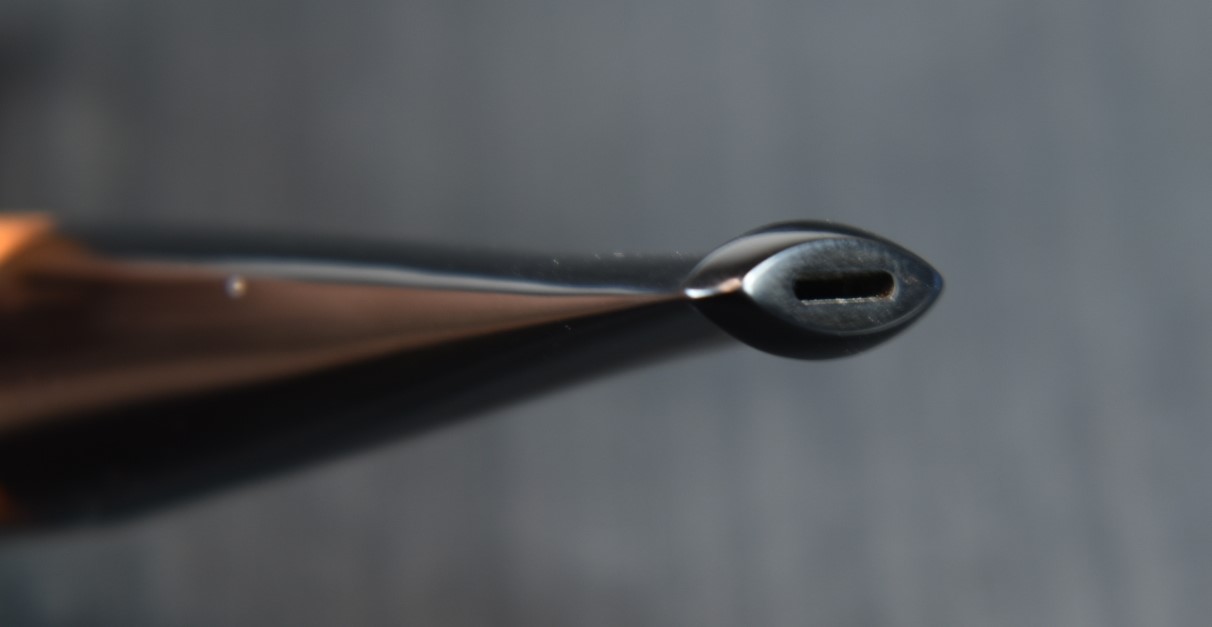

With the stem cleaned I started scraping the calcium from the button end of the stem.

The calcium in the tooth dents was problematic until I used a brass brush. The brush dipped in alcohol made the process quick and easy.

Below you can see that the dent on the bottom side was deep.

The stem cleaned out quickly with alcohol dipped bristle pipe cleaners.

Ready for gluing. Black cyanoacrylate (CA, super glue) was used to glue the stem parts back together.

Reaming the Tobacco Chamber

Once glued I turned my attention to the stummel while the CA was setting up. I gathered the reaming gear onto the plastic envelope I use as a reaming surface; the PipNet with #2 and #3 blades, Smokingpipes Low Country knife, General triangular scraper, the 220 sandpaper wrapped wood dowel and the 320 sandpaper wrapped Sharpie marker.

The PipNet with #2 blades enlarged the tobacco chamber by removing the first layers of cake. The cake was hard and brittle.

Subsequent reaming was done with the PipNet and #3 blades along with the knife and scraper. Once reaming was completed I sanded the interior with the 220 and 320 sandpapers to get to bare briar. This is when the first larger problem revealed itself. The chamber was charred with fairly deep burn damage. I looked like an over exuberant scraping had occurred and the charring occurred along the scraped surfaces.

I knew I would have to deal with the chamber interior in time. For now I continued with the exterior. The rim needed to be rid of the lava deposits. I did this with a sharp pocket knife and careful scraping.

Cleaning the Stummel

Next came the Murphy Oil Soap scrub. The Murphy’s was used undiluted and scrubbed with a medium bristle toothbrush. I should say the first application of Murphy’s was done as above. The second and third applications were also undiluted but with a more rigid nylon scrub brush. The stummel was very dirt and grime encrusted.

The stummel was rinsed with warm water and dried with a cotton dish towel.

I returned to the workbench and addressed the old crack repair glue. I used a pocket knife to carefully scrape the glue.

The same with the glue along the shank, careful scraping with a pocket knife.

Once the glue was scraped off I wiped the stummel off with a make-up pad dipped in 95% ethyl alcohol. The pad was removing some old finish or wax and stain.

There still remained a few shiny spots so I switched to acetone on a make-up pad and repeated the wipe. This eliminated the shiny spots and removed a bit more of whatever was left on the stummel.

I began sanding with the 320 sanding sponge. I wanted to remove the darkened briar from the rim without having to actually “top” it.. This worked, kind of. Oh, in the photo below you can see that tobacco chamber scrape burn scarring that I was trying to explain earlier.

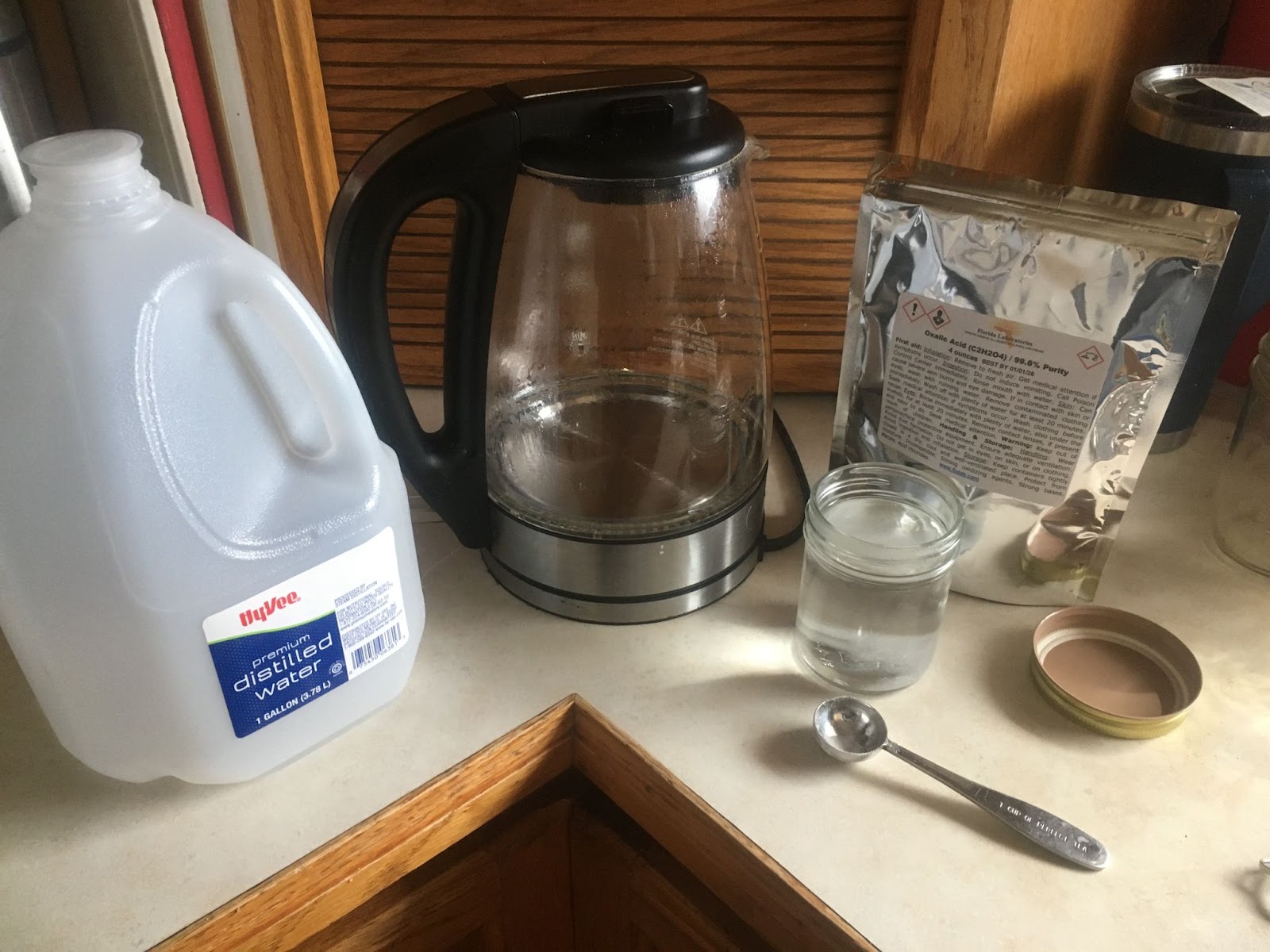

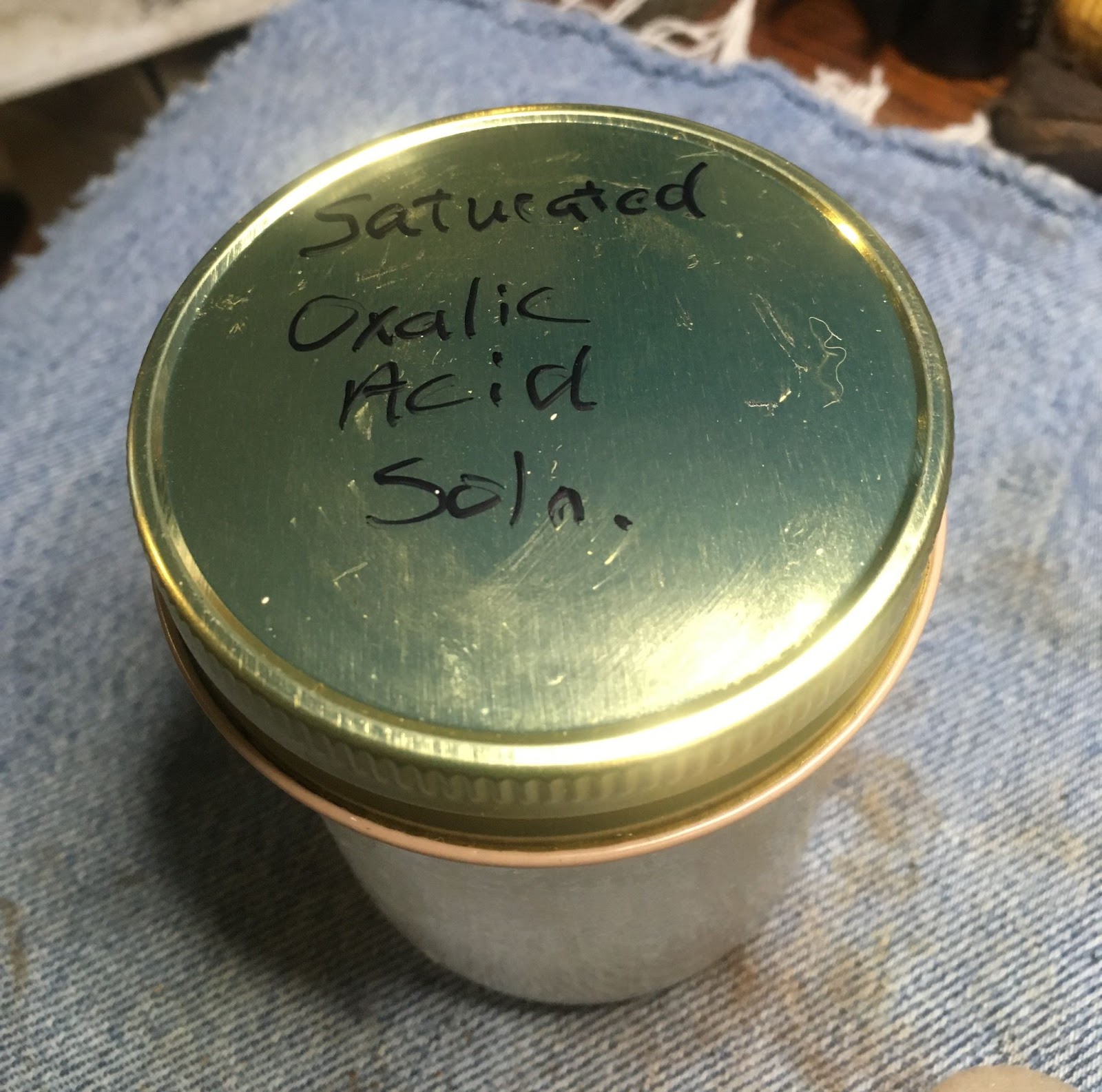

The rim remained darkened with char. Below you can see the rim is lighter but still not what I wanted. I had only used oxalic acid one other time. That was a technique that I want to add to my toolkit. Practice makes perfect, eh?

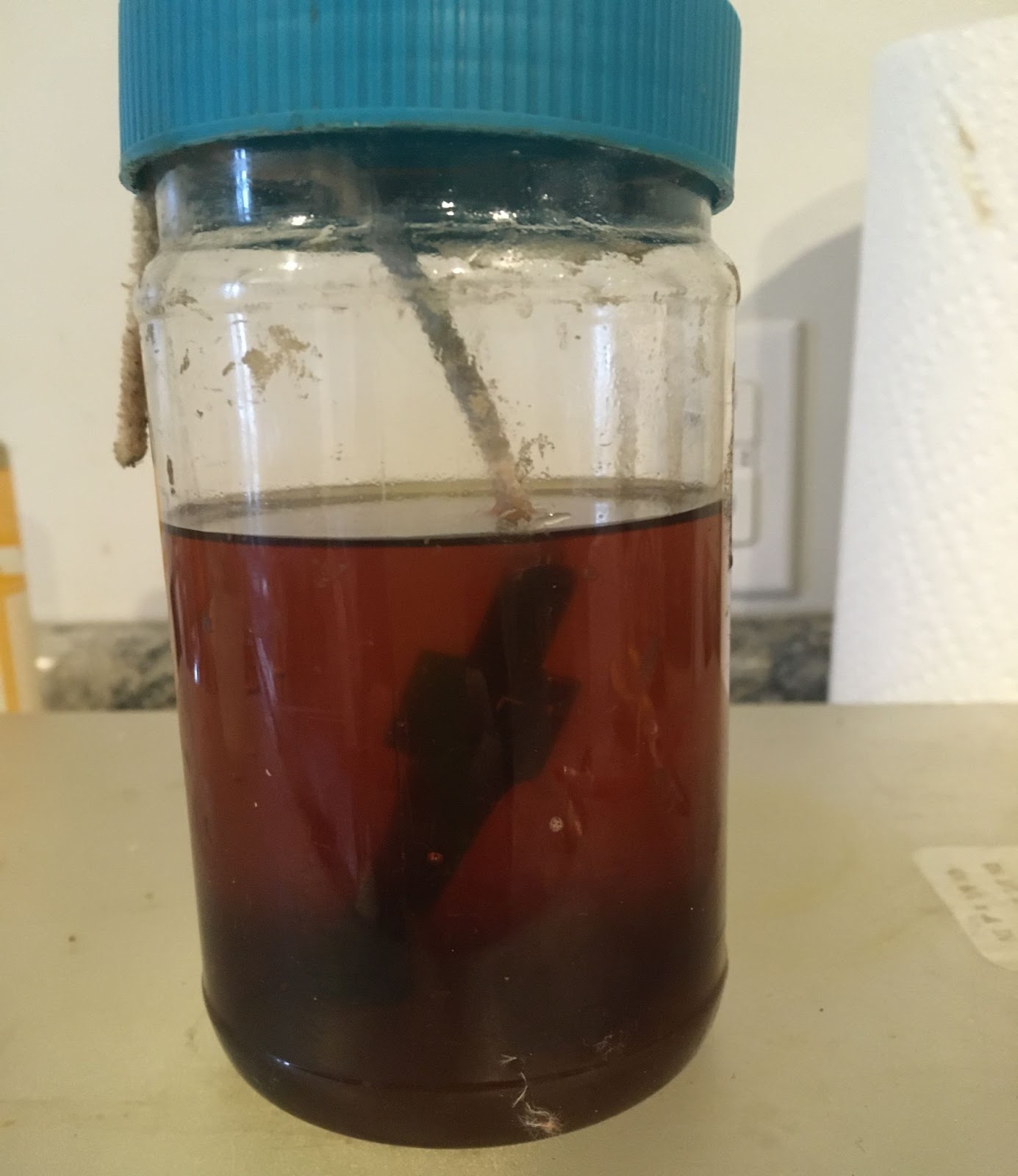

My jar of oxalic acid from last week.

Oh yeah, it is supersaturated now. New crystals growing in the jar.

I applied the solution to the stummel with a cotton swab and let it sit for 30 minutes.

After 30 minutes I applied a second coat and let that sit for 30 minutes. There is another better look at the tobacco chamber scrape charring (below).

During the hour that I was waiting for the oxalic acid to do what it does, I started working on another pipe. I really do not like having two projects going at the same time if I am trying to photo-document them. Hopefully the next pipe will be in a future blog. It is a Millard Dublin. Well, I guess I just ruined that surprise…

An hour later I took the stummel to the sink and rinsed off any of the white oxalic acid crystals and residue. I made a baking soda solution and dipped the nylon scrub brush into the baking soda and scrubbed the stummel. I re-dipped the brush many times in an attempt to neutralize the oxalic acid with the baking soda.

I returned the stummel to the workbench and wiped the stummel with a make-up pad dipped in 95% ethyl alcohol. Below are photos where I tried to show the lightening of the briar by the oxalic acid and the tobacco chamber damage.

The detail for the chamber damage is evident but the lightening with oxalic acid remained a work in progress.

Repairing the Tobacco Chamber

The next task was to deal with the tobacco chamber damage. I have successfully used J.B. Weld epoxy to repair heat damage like this before. I have also successfully used sodium silicate also known as waterglass in similar repairs. It had been a long time since I had used the sodium silicate so, I opted for it.

I used a disposable pipet to pull 2 ml of sodium silicate from the stock bottle and placed it onto a plastic tray.

I then opened a capsule of activated charcoal and mixed ½ of the contents to the sodium silicate.

The mixture was stirred with the pipe spike on my pocket knife. Once mixed the consistency was that of room temperature butter. It would spread but not flow. The spike was used to apply the mixture to the interior of the chamber filling the grooves. I put on a nitrile glove and used my finger to work the mixture into the rough areas and smooth the interior surface.

The stummel was set aside to dry for 24 hours. This is not a magic number. That is just how long I waited to sand the chamber. I still worked on the pipe since the sodium silicate was not flowing and had set-up within 20 minutes.

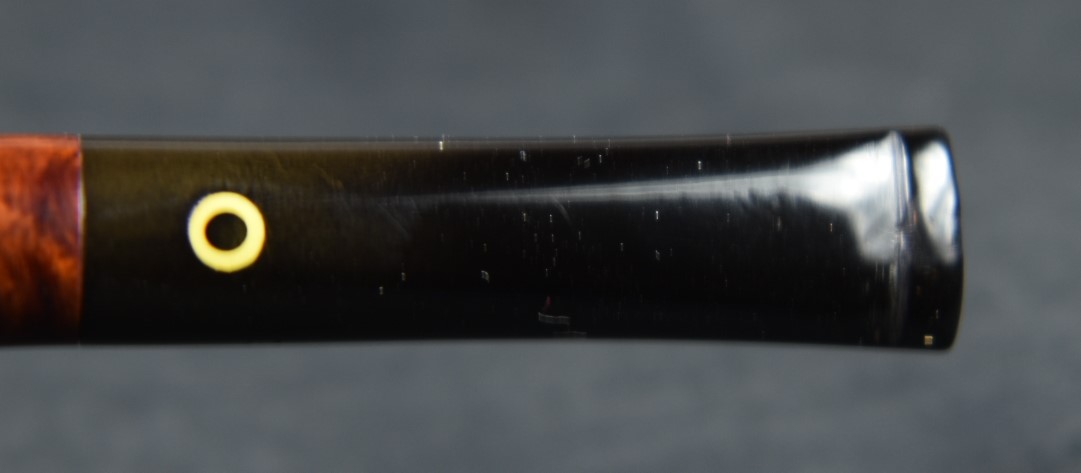

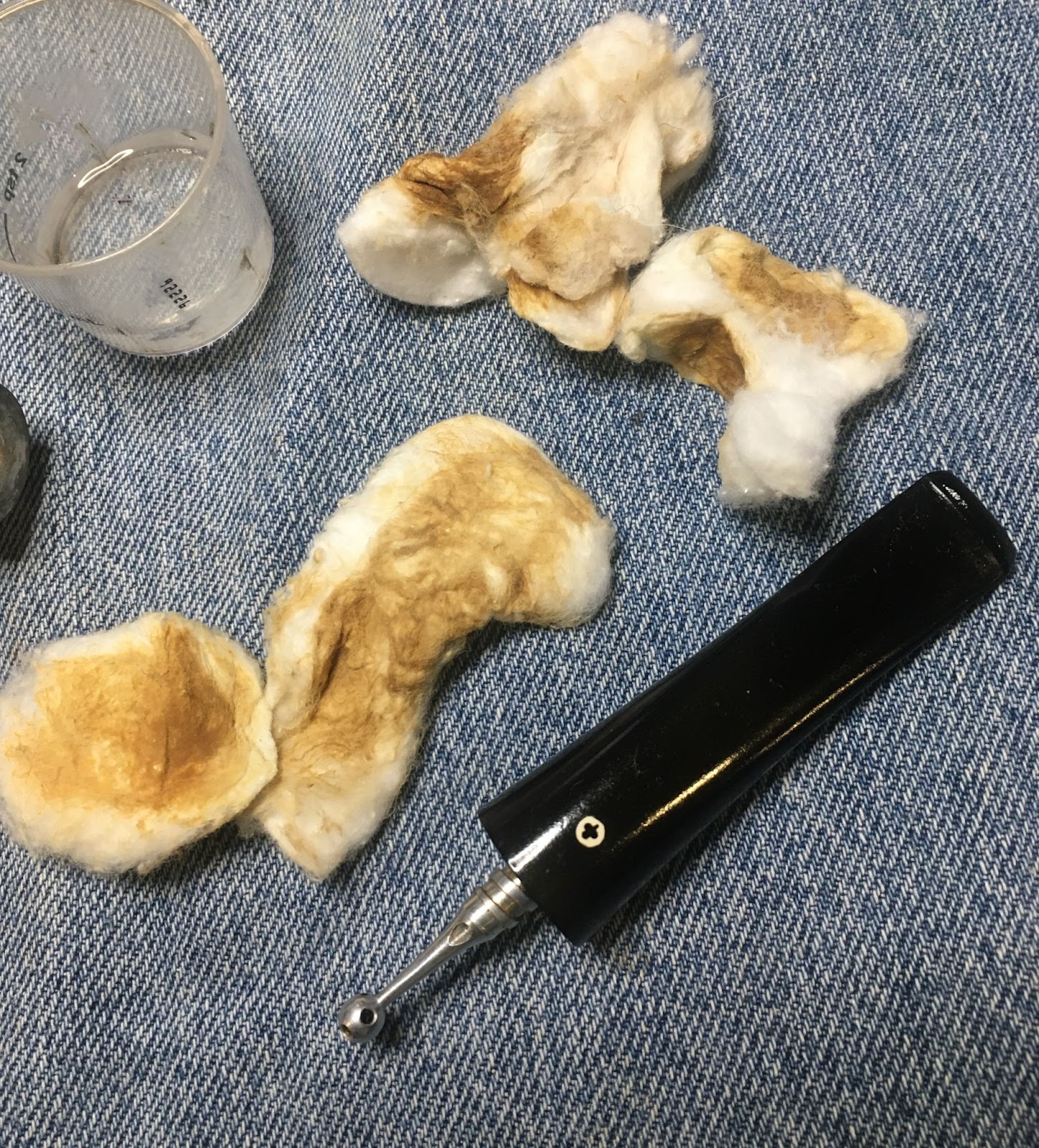

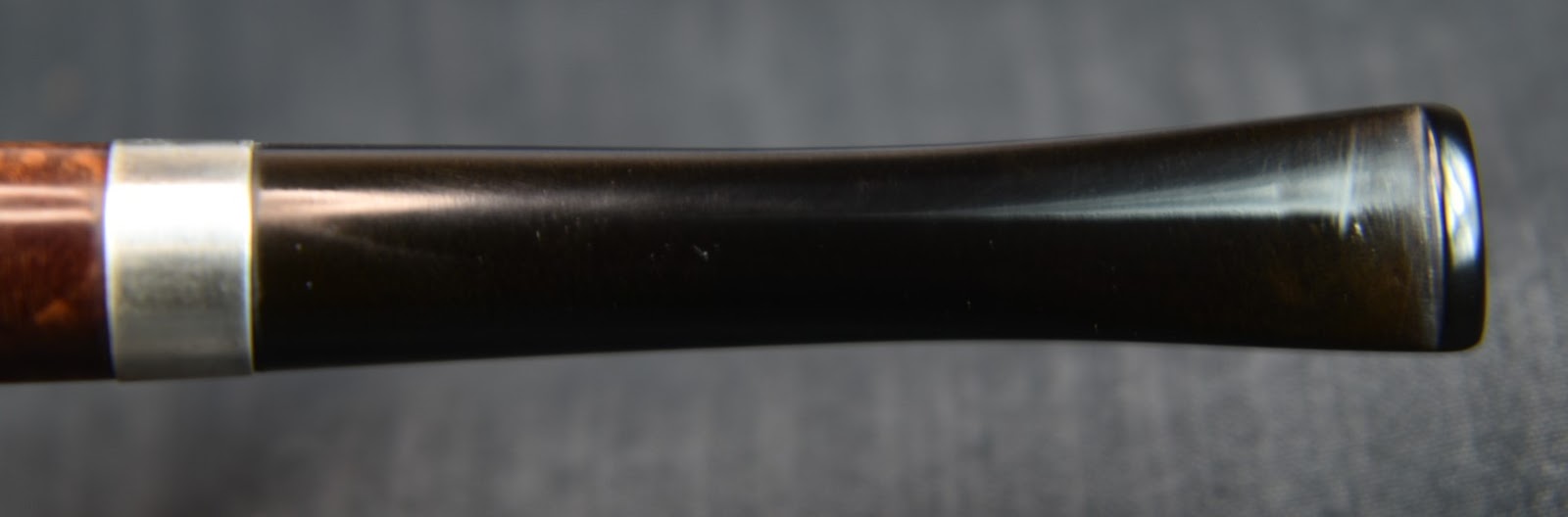

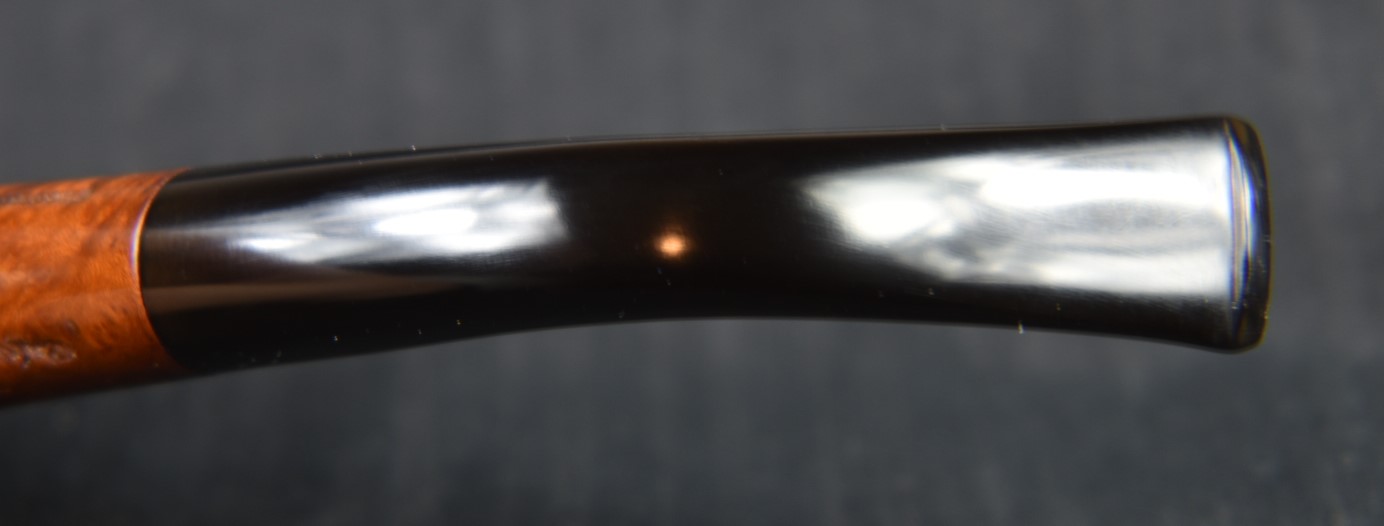

Repairing the Stem

While the sodium silicate was drying I continued to work on the now dry stem. I have to say, this may be my best documented stem rebuilding yet. Still not perfect but pretty complete. This stem was acrylic not vulcanite so there was no oxidation to deal with. I sanded the area that I was going to work on to roughen the surface and aid the CA sticking to it. Then I applied drops of black CA to the dents. None of these dents were too deep so I thought only one application would be sufficient to fill them.

Next I use a CA drying accelerator to spritz the wet CA . I did not photograph that stem but here is the product that I use.

The accelerator dries the CA in seconds greatly speeding up this process. Next, I filed the drops smooth to the acrylic stem surface with a flat needle file and smooth with a 320 and/or 400 sanding sponge.

The stem was wiped with a paper towel very lightly moistened with alcohol. This removes the sanding dust. I applied a drop of fresh black CA and spread it evenly over a larger area. The larger area makes it easier to blend the fills and is less noticeable when finished.

The larger area is spritzed with accelerator and again filed then sanded.

Tadah!

Now to rebuild the button. This is where my photo documenting went to heck. I used the cheap transparent Scotch tape, not the good stuff. The satin finish 3M tape, the good stuff, starts to dissolve with this accelerator while the cheap stuff doesn’t. I wrap the tape immediately behind the button sealing off the newly repaired surface from more CA. I then apply a layer of CA to the button. I then flip the stem over so the CA hangs down like a drop of water hanging off your fingertip. While holding the stem upside down I spritz the CA with the accelerator. Then before the CA completely sets up, you have about 3-5 seconds, I flip the stem back over and cut the still soft CA with a sharp knife along the back side of the button. This cut goes down to the acrylic stem. The Scotch tape is removed along with the excess CA that is now hard. Leaving you with a straight edge that requires little sanding or shaping. The button is then shaped with a needle file and sandpaper.

If you missed any of those steps, I will do it again with the bottom. And less typing this time.

Application of black CA to the dent. This one was deeper so a couple of applications were applied. Spritz with accelerator.

Apply additional CA, because it was a deep dent. Spritz with accelerator.

File the CA smooth

File and sand smooth.

Apply CA to a larger area. Spritz with accelerator. File and sand smooth.

Tape with Scotch tape.

Apply a layer of CA to the button. Invert and spritz.

Before it hardens, cut along the edge of the button with a sharp knife.

Peel the tape off along with the cut-off CA.

Shape the button with a file and sandpaper. Tadah! Now you know my process.

Filling the flaws in the Stummel

This stummel needed only a few fills but two of them were big ones; the crack at the bowl-shank junction and the bottom of the shank were long. I used a fine sharp dental pick to get as much material out of the crack as I could. Next I applied a layer of Thin CA with a fly tying bodkin to the crack, the thin CA flowed readily though the crack. I then sanded the crack with a dust filled (AKA dirty)sanding sponge. THe dust from the sponges along with new dust generated by the sponge filled in the crack and combined with the thinCA to fill the crack. It still was visible as a CA Fill appears dark but it was a strong smooth surface.

The pits on the stummel were filled using briar dust pushed into the pit. Then a small drop of Thin CA was applied to the dust. The CA soaked into the dust and affixed it to the surrounding briar. The surface was then sanded smooth.

Contrast Staining the Stummel

I was not happy with the oxalic acid lightening of the briar. I think I need more patience. I will continue to practice. Below you can see the pipe sanded from the 400-1000 sanding sponge. It was ready for the next step on my impatience.

Rather than patience and practice, I chose to contrast stain the stummel with Black Fiebing’s Leather Dye. I gathered the dye materials: Fiebing’s black, a pipe cleaner to use as an applicator, a disposable lighter, and covered the work surface with paper towels.

Below the stummel has been dyed black and flamed. The flaming is just that, since the dye is an alcohol based dye, flaming it lights the stummel on fire burning off the alcohol. There is a pretty blue flame that goes out quickly but the heat helps the dye set to the briar. THe whole thing is pretty much dry immediately after the flaming.

Since I did not care to let the dye dry, since I was going to be removing it from the majority of the stummel. I did not wait for it to dry completely. I started sanding with a 320 sanding sponge to remove the outer surface that was just dyed. The dye penetrates the soft textured briar more deeply than the harder briar. By sanding the surface I removed the outermost layer of briar leaving some of the grain darker from dye than other grain. THis accentuates the grain and darkens the whole stummel slightly.

More sanding with the 400-1000 sanding sponges. Care was taken around and on the stamps to remove as little material as possible to retain as much of the stamp as possible.

Now I was back to where I was before I dyed the stummel and it was bedtime.

Final sanding and Micro-Meshing

The next day was spent typing up this monstrosity of a restoration. I am so looking forward to doing a couple easy ones after this and the preceding restore. Anyway, the sanding employed the 1500-3500 sanding sponges in sequence. Between each sponge the stummel and stem were wiped with an alcohol wetted make-up pad.

Next, I used the 4000-12000 micro-mesh pads in sequence. Between the pads the pipe was wiped with an alcohol wetted make-up pad.

The pipe then received a coating of Before and After Restoration Balm.

The balm was allowed to sit for 45 minutes then it was wiped with an inside out athletic sock.

I was finally getting close to finishing this project. I polished the stem with Before and After Fine Polish followed by Before and After Extra Fine. Each polish was hand rubbed using a soft cotton cloth.

The pipe was reassembled and taken to the buffer for several coats of carnauba wax applied with the flannel buffer wheel. There are stories of how Civil War surgeons were rated by how much blood they wore on their aprons. More blood equated to a better surgeon. If that holds true for pipe restorations then I must be a truly amazing pipe surgeon. I mean look at the denim piece on the work surface (AKA, my apron).

Overall I am darned glad this restoration is over, I mean I am happy with the way this pipe turned out. The gluing of the stem is secure and looks like nothing ever happened. The acrylic stem polished nicely. The contrast stain looks good and conceals the blemishes of the rim charring. The tobacco chamber repairs resulted in a smooth chamber that will receive a bowl coating of maple syrup and carbon powder in the morning. While the two large cracks are still obvious they are now smooth and have lost the Braille texture and appearance. This Passatore is a pleasure to hold and to clench. It is a super feeling little pipe. I am not sure what Passatore calls the shape 349 but whatever it is it is a great little shape in hand. I do hope that you not only survived the longest pipe restoration in the world but also can use something from this in the restorations or pipe care of your own. If you like this sort of thing, please click the like and subscribe buttons. I thank you for sticking with this blog and reading the ramblings of an old pipe lover.

Below are some photos of the finished Passatore 349.

The interior looks rough but it feels smooth.

There is a slightly noticeable color difference between the black acrylic and black CA stem