Photographed and written by

John M. Young

Have you ever had what you think is a great idea, one that you are sure will work, but that no one else thinks is plausible? Well, that is how this project started. If you’ve read my ramblings for a while, you have probably read about discussions with Sascha Mertens. He is a fellow piper and restorer from Germany. Although we have never met face-to-face we have been chatting online for well over a year. I value Sascha’s ideas, techniques and criticisms. We have sent various gifts to one another across the Atlantic like pipes and tobaccos which neither of us has easy access to. Sascha appreciates a good corn cob pipe and has mentioned that he likes how my Missouri Meerschaum (MM) Freehand

looks. Sascha also, like many Germans, prefers to smoke pipes with filters. That sparked my interest in converting a MM Freehand into a 9mm filtered pipe.

I started with an imagined solution: Drilling out the shank to a diameter which would fit a 9mm filter. Next came a bunch of measurements with my MM Freehand and the idea started taking root.

For this scheme to work I would need to drill out the shank and shorten the tenon on the existing bit. I didn’t like that idea, but it should work.

I sent the photos and ideas off to Sascha and he reaffirmed that it wouldn’t work. O ye of little faith. I think the doubt came from my placing of the filter in the shank rather than in the stem. Stem placement is more typical and standard. Not being standard, nor typical, I proceeded on with my grand plan.

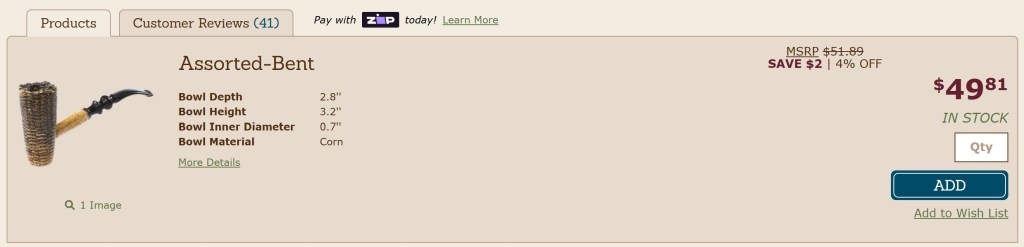

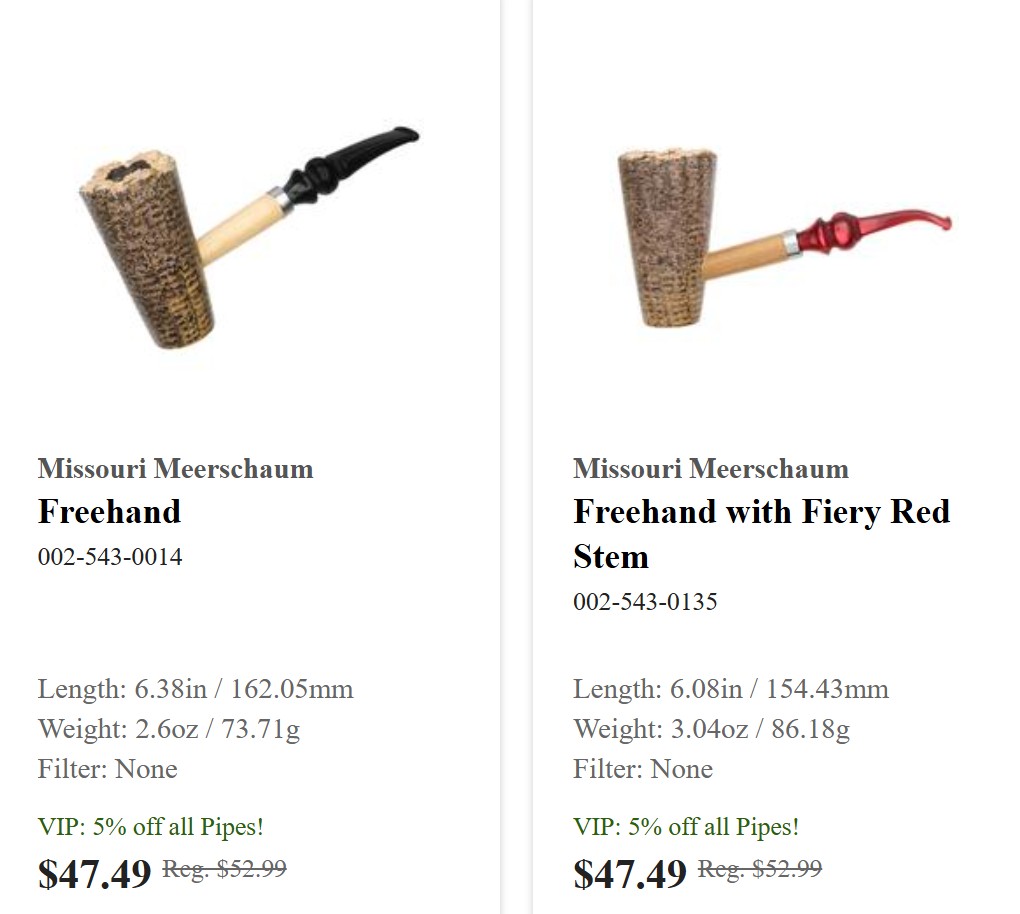

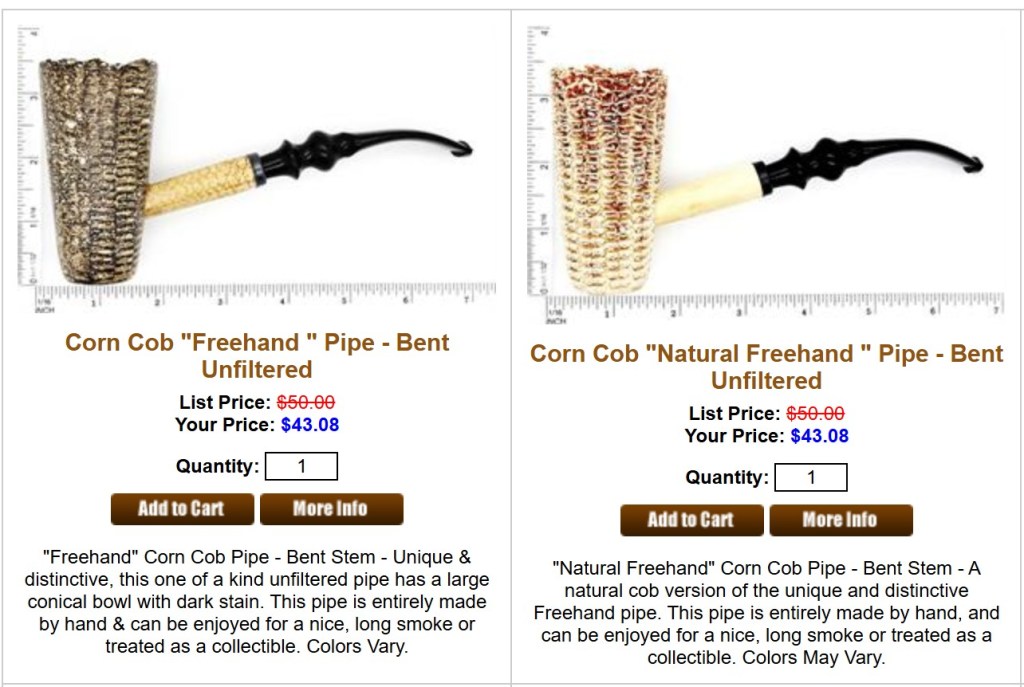

I sent Sascha several options of available MM Freehands from various sellers:

His response was simple and language-free:

The order was placed and the idea went to the back burner for a couple of weeks.

Last night, the patient made her way to the operating table. Apologies, I am getting ahead of myself, again.

The patient first had a date with the camera for some “before” photos.

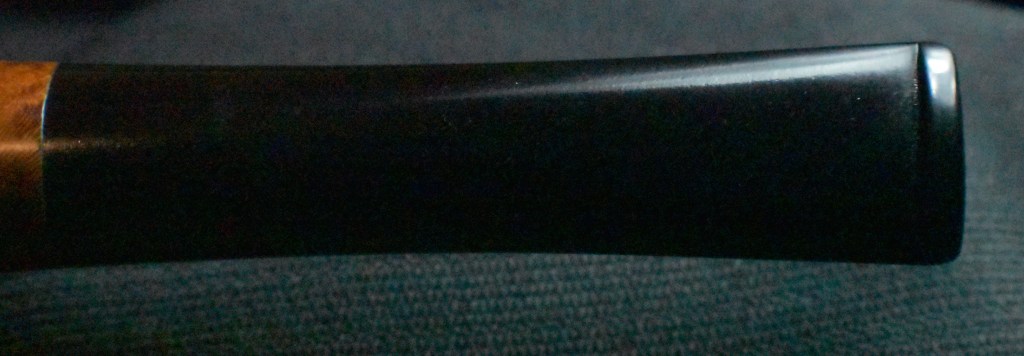

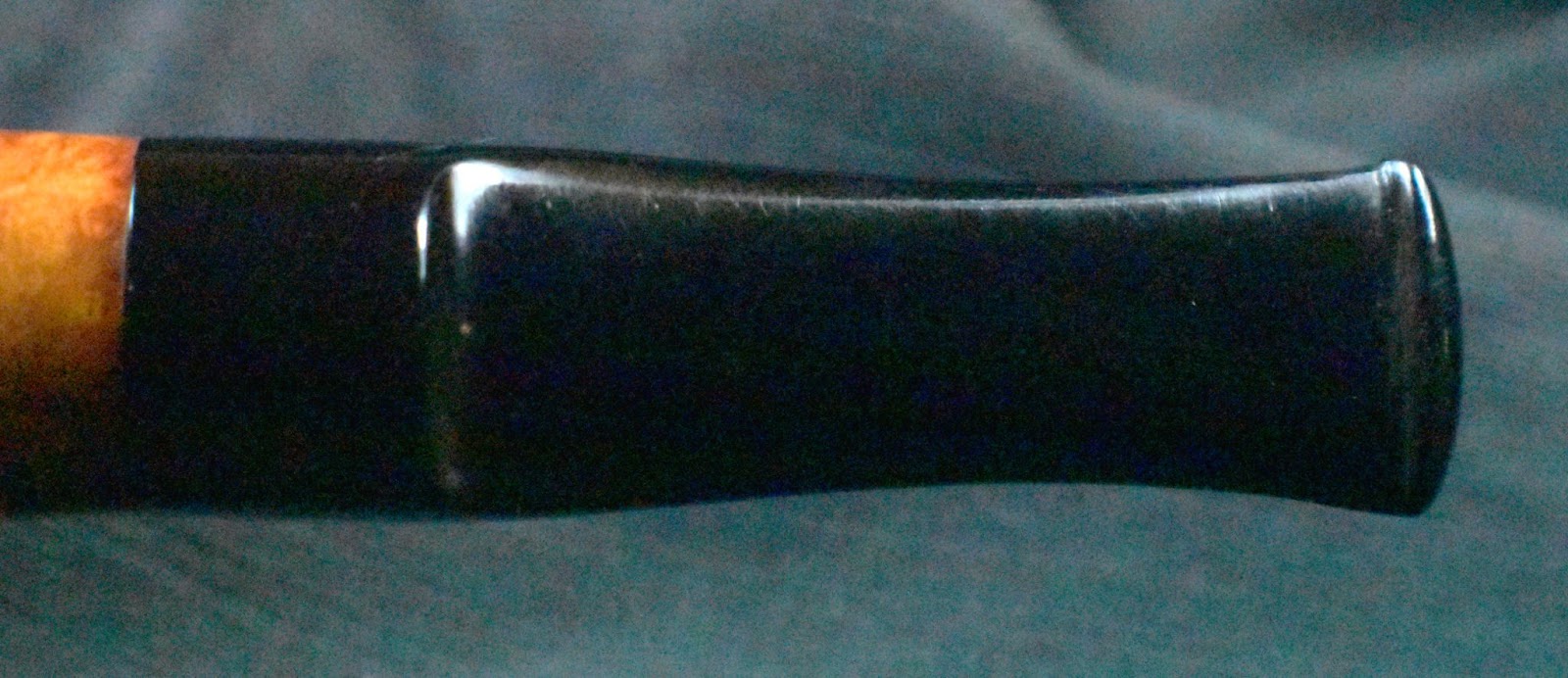

The Freehand looked typical for a new MM pipe. I was not impressed with the fit of the nickel collar. That would have to be redone and straightened. The stem was a beautiful dark grey metallic swirl stem, though it did fit rather tightly. The draft hole of the shank was slightly obstructed with drilling debris, an easy fix. I also debated myself about chiseling out the shank-end at the bottom of the tobacco chamber. Hmm, we’ll have to see if I want Sascha to experience the not so wonderful flavor of hardwood smoke when his first couple of bowls of tobacco burn the shank end. Muwahaha.

After the photo session the MM Freehand made its way to the workbench and its denim piece.

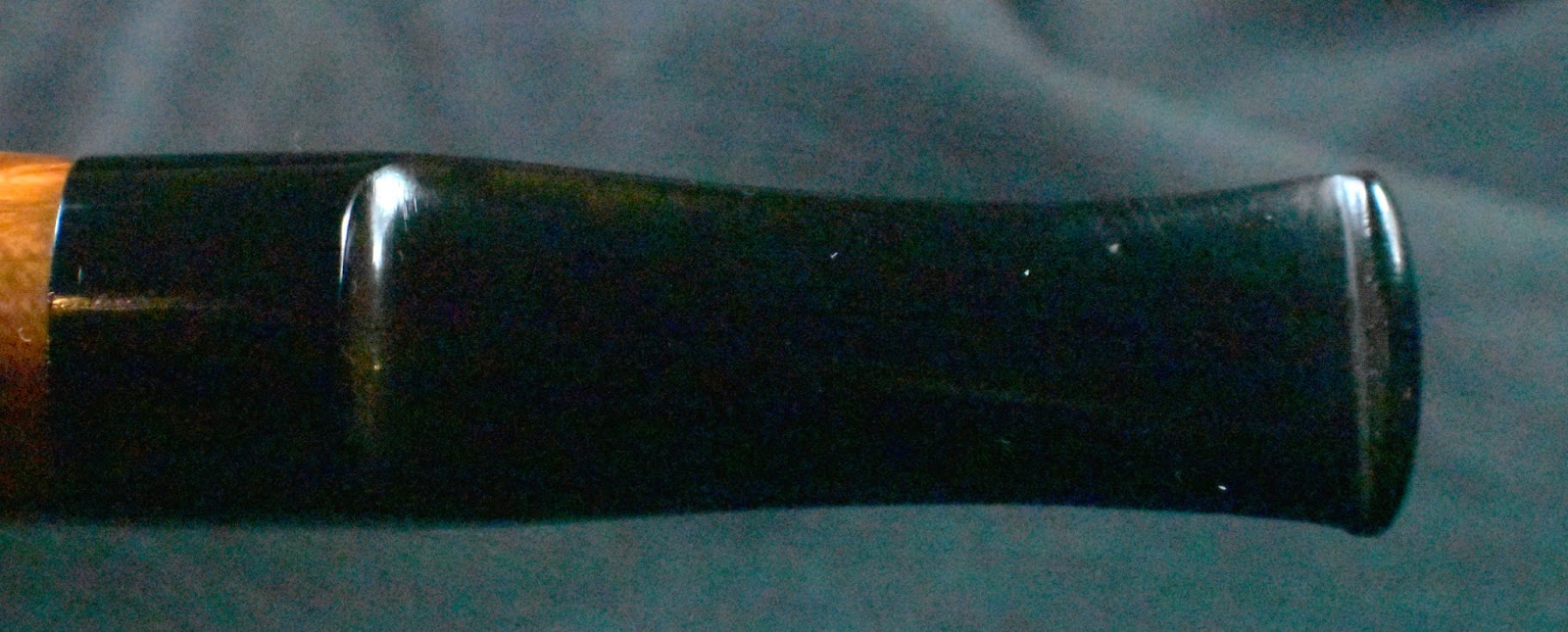

The collar came free with a little effort and strong finger nails.

Come one MM, I think your quality control could be a little better for your high-end cobs. Maybe I am too demanding or “high-end cob” is an oxymoron. The dented shank shows the ill fit of the collar better than my earlier photos.

I only have 3 varieties of 9 mm filters and one, a Denicotea, I can’t find, so I used the Peterson and Stanwell filters as my guides.

The filters have a diameter of 8.03 mm. I am not sure why they call these 9 mm filters.

The Peterson has ceramic end caps with 5 holes.

While the Stamwell has a 6 axial snowflake pattern. Both filters fit well in the shank mortise.

Both filters were also 1.409 mm in length.

Or, 35.80 mm, for those of the European persuasion. Okay, I know that the US is nearly alone in retaining standard units and I fought students, for 33 years as a science teacher, to use metric units. Still, I am American and stubborn as a Scotts Irish Polack, because that is what I am. We kind of ignore the German heritage of my mother’s side because they were the boring relatives.

The mortise was drilled to a depth of 1.482 inches.

Yeah, that’s 37.64 mm.

The filter diameter of 8.03 was paired with my 8 mm drill bit. I wanted to extend the mortise drilling further into the shank to allow the filter and the tenon of the bit/stem. I marked this depth with a German made Staedtler pen. See, I am so multicultural…

The drill bit was then taped off with painters tape for depth management.

The drilling went smoothly with just a hand drill, due to that is all I have. There was a slight step where the two hold met within the shank. This step provided just enough friction to stop a filter from being dropped into place. Bah. I used a small rat-tail file and a small tapered half-round file to smooth off the step. It took what seemed to be hours but was probably ½ hour.

Finally the filter would drop in but not drop back out. Tapping the shank of the workbench freed the filter. Bad news: My worry was that during smoking the filter would swell with moisture and lodge itself in the shank. Good news: At least I know that the airflow is going through the filter and not around it. Okay, that is kind of a reach for the good news.

I thought that maybe more sanding of the new “filter chamber would improve the filter’s release and removal. I made a sanding tool from an Exacto knife handle (with the blade removed). I applied a contact adhesive to the 2 cm at the end of the handle. I then applied more contact adhesive to the back of a piece of sandpaper. Once they were both diy I rolled the sandpaper onto the Exacto handle. This gave me a sanding tool which would only sand the first 2 cm of the filter chamber and not make the mortise any more loose.

The sanding continued and the filters would slip in without any difficulty. When the stem was completely inserted it pushed the filter further into the shank. I would then remove the stem and the filter would be stuck in the shank of the pipe. I could wiggle it, showing that it was loose but the filter would not simply slide back out. I found the best way to remove it was to use very fine tipped forceps to reach into the shank and grab the filter. The fine tips would slip into the holes of the ceramic filter and the filter could then be twisted and pulled free. This was not an ideal situation but it appeared to be the best case scenario of converting this pipe to a 9mm filter pipe. I ordered a fine tipped “filter extractor” (AKA, forceps) to include in the package for Sascha.

I think the conversion of this Missouri Meerschaum Freehand to accept 9mm filters was a success. Sure, it was done in a non-traditional way. Fitting a filter into the shank of a pipe is not the normal way to fit a filter. However, I was able to maintain the original stem and shank of the pipe. By just looking at this pipe, you would never know that it has been altered. I remain uncertain about the need for a filter. Perhaps there are more people who inhale pipe smoke than I think. I will continue to not inhale pipe smoke and use filters infrequently, but certainly not judge anyone who prefers them. I enjoy Carey Magic Inch pipes with their papyrus filter and I will occasionally insert a 9 mm filter into my Peterson Pipe of the Year 2017. The short stem of this pipe is made a better smoking pipe with a filter.

I do hope that you have found something here useful to your own pipe care, maintenance or restorations. If you like this sort of thing, please click the like and subscribe buttons. Thank you for reading the ramblings of an old pipe lover.