Written and photographed by

John M. Young

Talk about seeing the writing on the wall. The Edward’s folks must have been big fans of the Old Testament. Okay, for those who are not as familiar with American idioms – (handwriting on the wall). The Edward’s pipes story is one of well timed business choices as well as great briar, talented craftsmen and good advertising.

(https://www.edwardspipeandtobacco.com/)

According to pipedia.org:

“Edward’s pipes were originally produced in Saint-Claude, France when Francais actually was a world-class pipe maker with longstanding business & political connections to Colonial Algeria that allowed them to obtain the finest briar.

During the tumultuous 1960’s, Edward’s created a business model to offer the finest briar available in both Classic and Freehand shapes – all at a fair price. They bought the company & equipment and cornered the market on the finest, choice Algerian Briar just before the supply vanished in political turmoil of Algeria’s independence. Edward’s packed up both machinery and briar-treasure to America, safely caching the essentials to create a new pipe-making dynasty. This was a coup, for the 70’s and 80’s were grim years for pipe smokers as quality briar all but disappeared.

Edward’s Design Philosophy is hard to pin down, think of their style as the “American Charatan” with unique & clever twists all their own. Today, they fashion pipes in several locations across the USA. All of Edward’s pipes are Algerian Briar – a fact very few pipe companies can claim, and all are oil-cured utilizing natural finishes – no strange concoctions are used to interfere in your tastebud’s dance with the briar. Algerian, Calabrian, Sardinian, Corsican – take your pick, but Algerian Briar is generally considered the finest smoking briar ever used. When combined with oil-curing, Algerian takes on a magical quality that even Alfred Dunhill recognized as far back as 1918 as the choice for both his Bruyere and Shell.

www.otcpipes.com has a nice collection of vintage Edward’s pipes along with scans of Edward’s catalogs.”

(Edward’s – Pipedia) Note: The above “www.otcpipes.com” gave me a “server IP address could not be found.” message.

The “tumultuous 1960’s”, is a very gently stated reference to the Algerian War of Independence from France followed by years of civil war within Algeria. The “tumultuous 1960’s”, had a human death toll of around 1 million people. If you are interested in the Algerian War, I linked it here. Needless to say, all that tumult affected the briar harvesting and exportation.

This Edward’s Canadian has what I think is a nickel band as it has no “sterling” nor 925 stamping. There are what look like hallmark stamps from an assay office but I assume those are decorative. The Edward’s stamp on the top of the shank is very light with only the “Ed” discernable. On the bottom of the shank there are stamps; ALGERIAN BRIAR (very light and barely visible), 2 (probably a briar quality stamp) and 271 (probably a shape number) The below photos show the Edward’s Canadian as it looked upon arrival.

The pipe definitely had some issues. The stem was badly oxidized. The band appeared to have some crystalline oxidation crust as well. The briar looked good with some cake and lava on the rim which hopefully was not hiding charring. It looked like a straightforward restoration of a used pipe that was 60 years old.

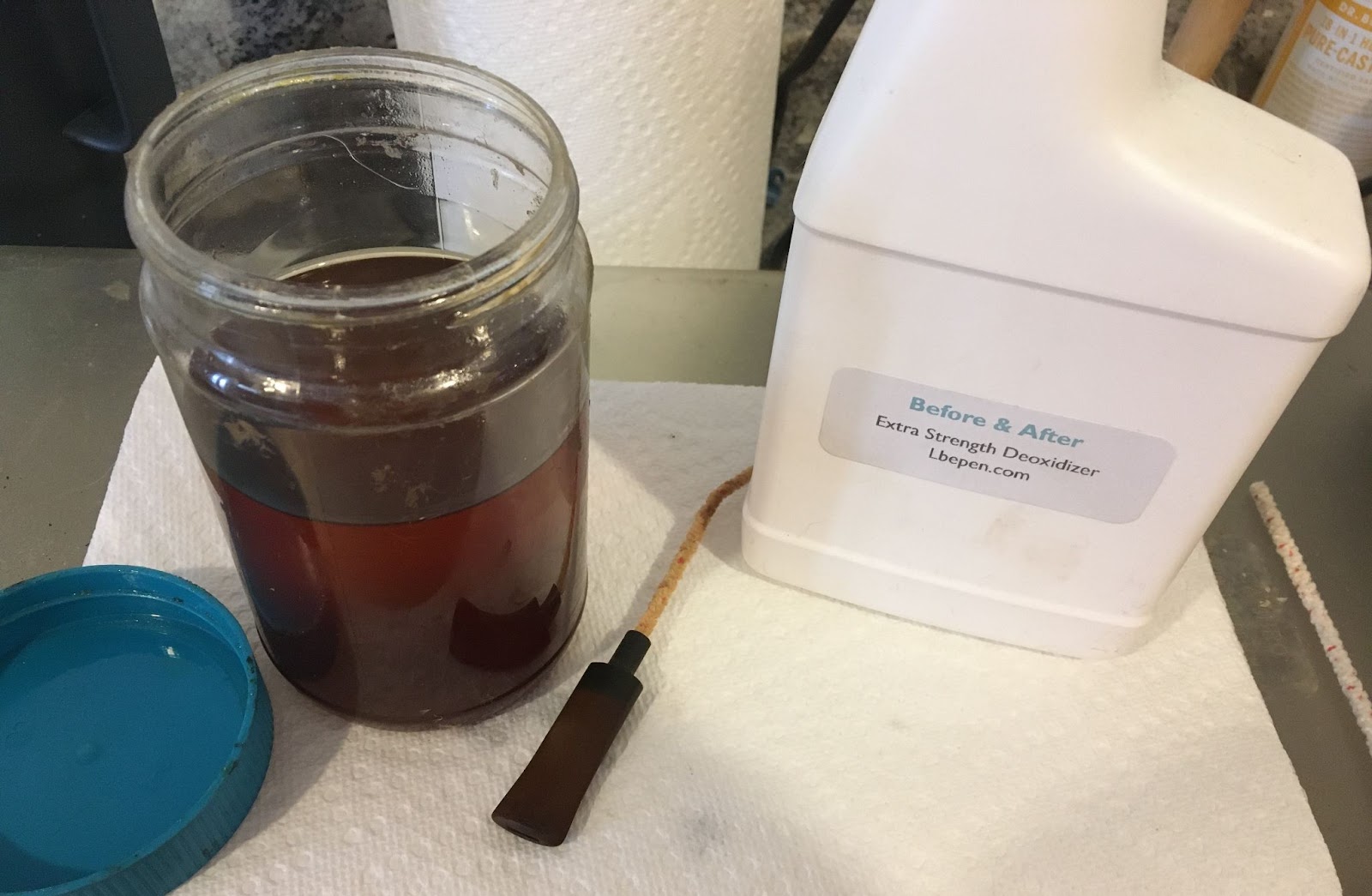

The first order of business was to get that stem into the stem into the Before and After Extra Strength Deoxidizer solution. I removed the stem and took it to the sink area. I laid down a paper towel to absorb the “It’s gonna happen” spills and ran a used pipe cleaner through the airway. If you don’t happen to have a used pipe cleaner laying on your counter, then I suppose you could use a clean one. As Ben Franklin is said to have said, “waste not want not”. I figured this old stem would require a couple of hours of deox (pipe restoration term for time in the deoxidation solution). The used pipe cleaner was bent over the jar edge and the lid loosely screwed on.

With the stem in deox, I began the tobacco chamber reaming. I used the Pipnet reaming tool with blade #2, a Smokingpipes Low Country knife and the General triangular scraper. The tools made the remaining easy or maybe it was the Algerian briar. I have had some Algerian briar that literally sloughs off deposited cake and this was one.

The reaming was followed by a sanding of the chamber with 220 sandpaper wrapped around a wood dowel. The interior of the chamber looked nice with no evidence of any damage.

Next the stummel was taken to the sink for a scrub with Murphy’s Oil Soap. I used a medium bristle toothbrush and undiluted Murphy’s to scrub away 60 years worth of accumulated dirt. The stummel was then rinsed with warm water and dried with a cotton dish towel. Upon returning to the workbench I wiped the stummel with a make-up pad wetted with 99% isopropyl alcohol. The pad removed some material and was slightly discolored.

Below are some photos of the stummel after the alcohol wipe

The rim needed to be lightly topped and given a bevel on the inside edge. I did this with a piece of 220 sandpaper laid flat on a countertop. The stummel was moved in a circular pattern and rotated in hand every could of circles to achieve an even sanding of the rim. This was repeated with 400 sandpaper. To bevel the inside edge I used a small piece of 220 sandpaper wrapped around a wooden ball.

After about 2 hours I retrieved the stem from the deox tank. That sounds so much cooler than the peanut-butter jar. I let the stem drip off much of the excess solution back into the tank. I then place the stem on a coarse shop rag. I rubbed the surface of the stem vigorously to wipe off the oxidized rubber.

It looked much better, black rather than sickly brown. I wanted to make sure the brown didn’t return anytime soon so I rubbed the stem with Soft Scrub with Oxy on a make-up pad removing even more of the oxidation from the surface.

I repeated that with a couple more make-up pads. I then gave the stem a coating of mineral oil with my fingers and set it aside.

While the stem was soaking up the mineral oil, I taped the stampings with painters tape. I wasn’t sure why since the stamps were so light I could barely read them anyway. Well the top “Edward’s” stamp and the bottom ALGERIAN BRIAR were light. The #2 and the 721 are nice and clear on the bottom of the shank.

I sanded the stummel with the sponges from the 1000-3500. Between each sponge I wiped the stummel with a make-up pad wetted with 99% isopropyl alcohol. I didn’t need to use the more coarse sponges since this pipe was in such great condition and this Algerian briar is very soft and the coarser grits would have been too aggressive. With the sanding sponges done, I removed the tape and started micro-meshing with the 4000 micro-mesh pad. I attached the stem and also used the pads on the stem. Between pads the stummel was wiped with a make-up pad wetted with 99% isopropyl alcohol. The stem was rubbed with a drop of Obsidian oil and wiped off with a paper towel between pads.

Once finished with the micro-meshing the stem was given a final rub with Obsidian Oil and the stummel had Before and After Restoration Balm applied and allowed to sit for 20 minutes.

After 20 minutes the balm was wiped from the stummel using the inside of an athletic sock.

The tape was removed from the band. I used the 6000-12000 micro-mesh pads to polish the band. At this stage the Edward’s Canadian was really looking great.

I got out the Before and After Fine and Extra Fine Polishes and used them on the stem and the band. The polish was applied with my finger and hand buffed using a cotton make-up pad.

The final step was to take the Canadian to the buffer and apply several coats of carnauba wax to the stem and stummel.

I am very pleased at how this Edward’s Canadian turned out. The only disappointment is the strength of the stampings. The grain is a beautiful mix of cross grain and bird’s eyes. Now that it is finished I kind of wonder how it would have looked with a contrast dye. Oh well, that would have completely obliterated the barely readable stampings but, I bet it would have made the grain really look cool. This shape is as traditional of a Canadian as possible, wonderfully proportioned oval shank with that elegant tapered stem. It is just a darn pretty little pipe. A credit to the craftsmen who made it and a blessing to it’s next pipe companion. I do hope that you have found something here useful to restorations of your own or at least found it entertaining. If you enjoy this sort of thing please, click the like and subscribe. Thank you very much for reading the ramblings of an old pipe lover.

Here are some photos of the finished Edward’s Canadian.