Written and photographed by

John M. Young.

A while back I discovered the cache of Pipe Lovers Magazines from 1946, 1947 and 1948. The articles were fun to read and the print advertisements provide an amazing source of information for research. It was during one of these reading sessions that I decided that I wanted to restore some of the pipes from the advertisements from the pages of Pipe Lovers Magazine of the post war 1940s.

Searching through eBay for estate lots which contained one or more of the makers proved to be fun as well. One listing that I came across was this one:

The description by the seller read as:

“This vintage Emperor Wally Frank smoking pipe lot includes a box of Empire pipes made in Brooklyn, NY. Crafted from high-quality BRIAR, this lot is perfect for collectors of estate tobacco items. The pipe features a unique body shape and is made by a renowned brand. The country/region of manufacture is the United States. This lot is a must-have for any serious collector of tobacciana and will make a great addition to any collection. All four pipes look in nice shape all are nice wood. Interesting box with instruction pamphlet ! Do not know a year I know nothing about these. My father had them. So please ask questions and look at all pictures took a lot not sure how many are Wally frank. All say imported BRIAR thank you.”

When the lot arrived I sent the seller a message saying that the pipes arrived and that everything looked good. I also usually ask the seller if they would be interested in seeing photos of the pipes after they’ve been restored. I received a message from this seller that read as follows:

“”Thank you very much they were my dads! yes would love to see them!!”

I am looking forward to sending them photos of the finished pipes. I then sent another message asking if they would be willing to share any other information about their father and his pipes. As of yet, I have not received any additional information. I realize that this is asking someone to share personal information and that not all people are comfortable doing that with a total stranger but, I was hopeful.

The first pipe that I decided to work with was a small lovat. The finish was rusticated in the same way that Custombilt or Marxmam rusticated some of their pipes. There were stampings on both sides and the bottom. Left side – EMPEROR over CUSTOM FASHIONED, right side – Supreme and bottom – CUSTOM FINISHED. I started researching Emperor with the usual starting sources pipehil.eu for logos and pipedia.org for information.

First I went to pipedia.org for information about the Emperor. According to the site;

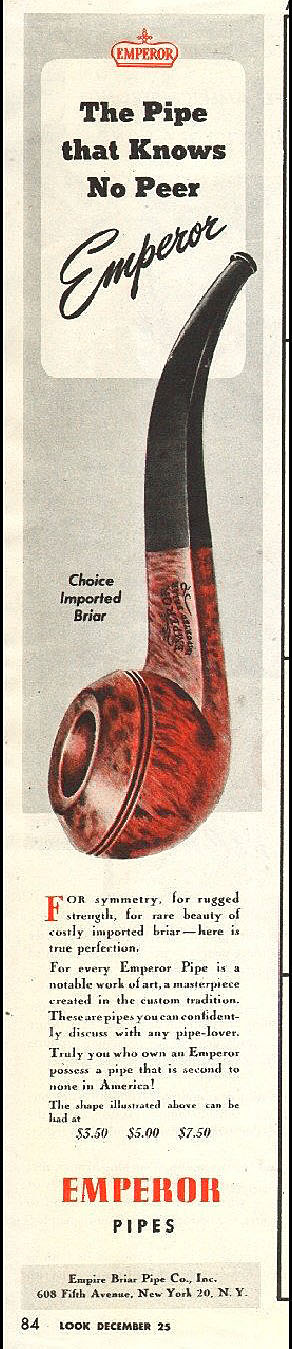

“Empire Briar Pipe Company Inc. of New York produced Emperor pipes. Known as “The Pipe that knows no Peer” as their 1945 advertising promotes. That ad reads “The pipe that knows no Peer. For every Emperor pipe is a notable work of art, a masterpiece created in the custom tradition.” They are a subsidiary of the Continental Briar Pipe Co. Inc. 80 York Street, Brooklyn, New York.

They had Three grades: Standard, De Luxe and Supreme.”

Pipedia also had an example of an Emperor store display and advertisements from the late 1940s courtesy Doug Valitchka. Thank you, Mr. Valitchka.

THis next image set me straight as to the name of this shape. I had been calling it a lovat. In looking at the names Emperor gave this shape I will henceforth (and in the title) call it a Medium Golfer. THough it is not quite an exact match for the shape of this pipe it is the closest match I can find for an Emperor so, That is what I’m calling it. If you have additional information please feel free to include it in the comments.

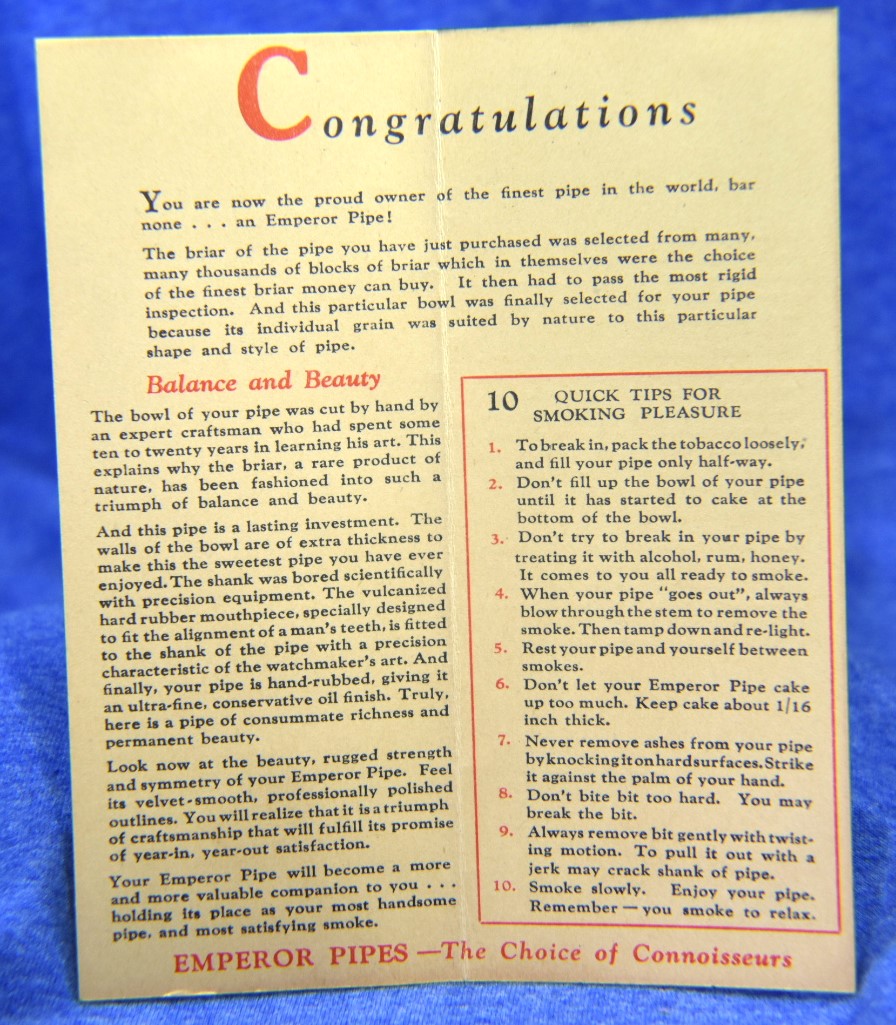

And for the last advertisement an image of the stinger or, rather the “Keystone Cleaner” For some reason I envisioned Charlie Chaplin and the Keystone Cops with brooms when I read this.

The next stop was pipehil.eu we can see the logos stamped on representative pipes in their collection of images:

(Em-Eq — Pipes : Logos & Markings (pipephil.eu))

The Medium Golfer on the desk beside me shares the Supreme stamp and the EMPEROR over IMPORTED BRIAR but does not have any stamps on the stem. This is probably due to the short saddle stem shape not being conducive to stamping.

The final bit of research was done perusing the 1946 and 1947 Pipe Lovers magazines. There I found a couple of references to Emperor. Item one is for an essay contest as the first prize.

(Pipe Lovers Magazine February 1947 p. 60)

And the second is a “What’s new” article also from 1947, from the July issue. This closely describes the carving style of this Golfer.

(Pipe Lovers Magazine July 1947 pp. 219-220)

Based on the above, I would say that this Emperor Supreme Medium Golfer was made by the Empire Briar Pipe Company Inc. and was carved at 80 York Street, Brooklyn, New York sometime around 1947. This pipe represents one of their highest grades, the Supreme.

Now, let’s see what it looked like upon arrival. Okay, as a disclaimer, this is kind of a set-up. There was another Emperor pipe in the box upon arrival. The other pipe was an Emperor but it was not a Supreme it was a De Luxe (their spelling not mine). Everything else is as-found upon arrival. THe pipe was in remarkably good condition.

This really looked more like a clean-up rather than a restoration. I planned to ream the tobacco chamber, clean out the airway, sand the light scratches on the stummel and stem, micro-mesh the pipe, give it a Restoration Balm coating and buff with carnauba wax.

I started with the reaming. The pipe is small and none of my reaming tools would fit the tobacco chamber. The diameter measures .67 inches or 43/64 in. Who the heck has ever heard of that drill bit? It is in between ⅝ and 11/16 inches although it could be a 17

mm. I used the Smokingpipes Low Country knife and the General triangular scraper to remove the minimal cake. This was interesting, the cake seemed to just slough off the chamber interior. It was obviously an old cake but it came off very easily. I have experienced this before with Algerian briar in Marxman pipes. They just seem to shed the cake with little effort. After the scraping, I sanded the interior of the chamber with 220 sandpaper wrapped around a wood dowel.

Next I addressed the shank airway. Cotton swabs dipped in 99% isopropyl alcohol were used for the initial scrub attempt. Once the tars in the airway started to soften the swabs became darkly stained. I then poured about 3 ml of alcohol into the tobacco chamber allowing some of it to flow into the shank. Holding the stummel at an angle to avoid pouring the alcohol on my jeans I used a nylon shank brush to scrub with the alcohol. I scrubbed and twisted the nylon brush. The brush was removed and wiped by pulling the bristles through a paper towel. I then used a couple of cotton swabs to scrub and absorb the remaining alcohol. THis was repeated until the swab emerged clean.

After the shank was cleaned I turned my attention to the stem. The stinger was definitely unique. It showed evidence of quality machine work and surprise – it is threaded into the

stem. I soaked the stinger in alcohol while I ran alcohol dipped bristle pipe cleaners through the stem. The stinger (Oh wait, Keystone Cleaner) was scrubbed using a piece of 0000 steel wool dipped in alcohol. Once cleaned the stem was reassembled.

The stummel was then taken to the sink for a cleansing with Murphy’s Oil Soap. There didn’t appear to be much dirt or grime on the stummel but the thing is still 76 years old and a bath is rarely a bad idea. I used Murphy’s undiluted and scrubbed with a medium bristle toothbrush. The Murphy’s was rinsed with water and the stummel dried with a cotton dish towel. Upon returning to the workbench I wiped the stummel off with a make-up removal pad dipped in 99% isopropyl alcohol. The pad discolored slightly during this rubbing. It looked like it may have been dissolving some of the dye from the briar.

I then rubbed the stummel with a make-up pad dipped in acetone to see what that solvent would do. It appeared to remove a bit more color though neither of the pads affected the overall finish of the pipe.

I then taped the stampings with painters tape for their protection. I began sanding with the 1000 grit sanding sponge. I used the sponge with a light touch and did not try to sand

any of the carved grooves on the stummel. I sanded the stem at this time with the same sponge. I moved up through the sponges from 1000 to 2000 then 3000. I wiped the stummel with a make-up pad wetted with alcohol between sponges and the stem got a drop of Obsidian oil rubbed in with my fingers and wiped with a paper towel. After the 3000 sanding sponge I removed the painters tape and micro-meshed the stummel and stem with pads 4000-12000. I again wiped between pads the same way that I did between the sponges.

After the 12000 micro-mesh pad was used on the stem I did a final polishing with Before and After Fine and Extra Fine polishing compounds. They were applied with my finger then hand rubbed with a soft cotton rag.

The Emperor was really starting to look fantastic. I applied a coating of Before and After Restoration Balm to the stummel and let it set for about 30 minutes.

After about 30 minutes I wiped off the Restoration Balm using the inside of an athletic sock. Wow, I thought that it looked good before.

All that remained was for me to apply a few coats of carnauba wax the pipe and take some photos.

When I opened the package with the four pipes in this lot the phrase “pleased as Punch” came to my mind. “What the heck does that mean?” asks anyone who is not old. “As pleased as Punch means to feel a great sense of delight.” Feel free to click the link for the citation. The other Emperor in the lot will be in a near future blog. I believe the briar to be Algerian similar to the briar used by Pipe by Lee and Markman. It is very soft and has a quality that I cannot define well but know when I see it. The pipe is relatively small measuring in at 5.5 inches long (140 mm), 1.4 inches tall (40 mm) and 1.13 inches wide (29 mm) with a weight of 1.1 ounces (31.3 g). The briar’s grain is difficult to discern with the carvings but I could not find any fills. It is just a little darling of a pipe. I hope that you have found something here that you can use in restorations of your own or that you were entertained. If you like this sort of thing please click the like and subscribe. Thank you very much for reading the ramblings of an old pipe lover.

Here are some photos of the finished Emperor Supreme Medium Golfer.

Yeah, I had to try that one out myself. It was so worth doing. Thanks again, John.

3 responses to “A Emperor Supreme Rusticated Medium Golfer Restoration”

[…] A Emperor Supreme Rusticated Medium Golfer Restoration […]

LikeLike

John, I really enjoy reading your posts. Not only do I get to read and see the restortation of a pipe, but there’s always a little humor thrown in. With you and Steve Laug, I am lucky to have two outstanding blogs to read.

LikeLike

Thank you. I’m awed being in the same sentence with Steve. I’m also a bit worried about your sense of humor… Seriously, thank you.

LikeLike