Written and photographed by John M. Young

The quest for a cooler smoke may lie at the heart of mans’ needs. Needs such as water, food, shelter, a mate, love, companionship, are there too. Okay, maybe not the “heart” but, at least the appendix or the spleen of mans’ needs. This quest has led to many unique inventions. One of these is Tracy Mincer’s Doodler. Tracy Mincer was the originator of the Custom-bilt pipes in 1934. Interestingly, the same year that Robert Marxman began the Marxman pipes company. The history of Tracy Mincer’s contributions to the estate pipes which we have available today can still be seen. I have a saved search on Ebay that alerts me everytime a Custom-built or Custombilt (the hyphen was used until 1946) pipes are added to Ebay. Today, thus far, four new listings have come up.

There is what sounds like a remarkable book about the Custombilt company by William Unger, Jr., Ph.D. titled, THE CUSTOM-BILT PIPE STORY. Pipedia has information at the bottom of their “Custom-Bilt” page that states the following:

“Available from the author (order from). 263 pages, plastic spiral bound, 87 illustrations: pipe photographs and reproductions of rare ads and catalogs. Chapter One: The Companies; Chapter Two: The People; Chapter Three: The Pipes; A carefully researched history of these increasingly collectible pipes, from their beginning, with Tracy Mincer in 1929, to their last manufacture in 1998. A guide to the names and distinguishing features of the many different variations. Reviews by Richard Esserman, and Tony Soderman.” (https://pipedia.org/wiki/Custom-Bilt)

The “order form” link takes you to http://naspc.org/books.htm which unfortunately is not currently functioning. However the site does say. “This page is currently blank – we are working on bringing content here, so stay tuned in the future.” (http://naspc.org/books.htm) So, I will continue to check the site in hopes of a functioning webpage. The reviews by the above gentlemen, Esserman and Soderman, are also quite interesting and make me wish I could obtain a copy of the book.

As for the history of the Doodler, Pipedia states that:

“After his loss of the Custom-Bilt name in 1953, Tracy Mincer‘s next production pipe was The Doodler. The pipe was turned for Mincer by the National Briar Pipe Co. beginning in the early 1950’s, and that company eventually purchased the pipe design in approximately 1960. After that time Mincer’s former partner Claude Stewart began making a line of pipes called the Holeysmoke which were largely identical to the Doodler pipes, and National Briar continued to produce the Doodler. The pipe’s design centers around a series of vertically drilled holes in a ring around the combustion chamber, meant to provide airflow and a cooler smoke.” (The Doodler – Pipedia)

In reading the Mincer page at pipedia, parts of this passage funny,

“in the early 1950’s, Tracy Mincer developed severe financial problems that caused him to stop making the Custombilt, and he lost the name. In 1952, Mincer began a new pipe, The Doodler, that due to the holes in the bowl had to made primarily in a billiard type shape in three sizes. In the early 1950s, National Briar was turning the bowls for Mincer. Based upon the documentation, it appears that Mincer made the pipe until the mid 1960s, when National Briar Pipe Co., Inc. began making and selling the Doodler.

Mincer died in 1964.” (https://pipedia.org/wiki/Mincer)

Not to make fun of the deceased but rather the writer of the piece. Death in 1964 certainly would cause one to stop making pipes in the mid 1960s. Even after his death the Tracy Mincer name was still used to market and sell pipes.

“Claude Stuart purchased the Tracy Mincer Pipe Company and began making pipes using the Tracy Mincer stamp. Stuart finished nearly all the pipes produced, mostly carved and textured bowls and the occasional straight grain. Claude made the Tracy Mincer Pipe Company a moderate success. Stuart became ill and in 1990 The Tracey Mincer Pipe Company went out of business. Currently, Jim Tedesco owns the Tracy Mincer name.” (https://pipedia.org/wiki/Mincer)

The stamping on my Doodler was the same as those pictured on the Pipehil.eu site:

(http://www.pipephil.eu/logos/en/logo-t4.html#thedoodler )

This brings me to the conclusion that the pipe I have is a Doodler, profound, eh?. I cannot be sure as to when it was made since the years of manufacture were from 1953 -1960s. Mincer’s death in 1964 did not apparently end the production of Tracy Mincer’s pipes. I like to think that the pipe I own was an earlier version due to the carved gouges at the bottom of the stummel or heel. These are more reminiscent of the Tracy Mincer Custombilt pipes and may be a carry over from his experiences there. This of course is all just conjecture.

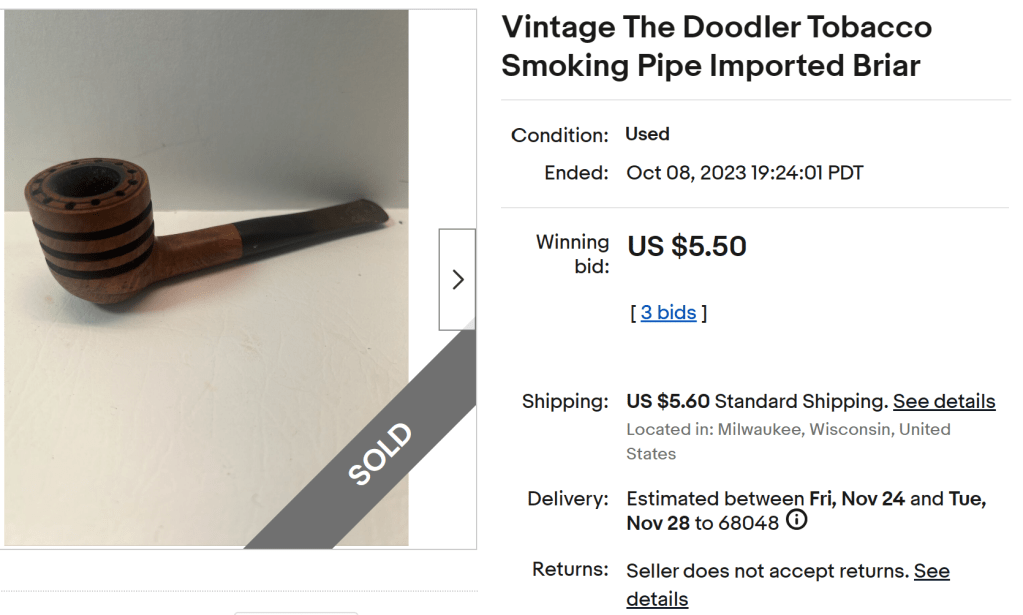

How did I come to own this particular Doodler? I won it on an Ebay auction. The pipe had piqued my interest and I had been watching auctions for a

couple of weeks. Finally I won the pictured auction. I know, big spender, right? Well, I am a big believer in the saying, “better luck than good, anyday.” The pipe arrived and I was quite pleased to see that the lighting in Ebay the photos were not very good and the pipe appeared far nicer than the photos.

This appeared to be a nice easy restoration. Actually, more of a clean-up. A clean-up with a stem restoration. I started with reaming out the tobacco chamber. There was minimal cake build up to remove. Sorry for the lack of photos – this whole process went so quickly I kind of forgot to document the it. After the minimal reaming I sanded the interior of the bowl with 220 sandpaper wrapped around a wooden dowel.

There was some charring or lava around the rim. I figured I would start with the Murphy Wood Cleaner and see what that revealed. The Murphys was applied to a medium stiff toothbrush undiluted. This was used to scrub the entire exterior, without the stem. As usual I was amazed at how much grime a pipe that looked so clean actually has. The deposits on the rim were just lava and came off easily with the scrubbing. I rinsed the stummel with warm water and dried it with a cotton towel. I returned to the workbench. The amount of rinsing was minimal and the bowl was spacious enough that I dried the stummel more thoroughly with paper towels. Getting into all of the spaces between the rings was tedious but easy to accomplish.

I did notice that the vertical holes drilled from the rim through the rings was not done with extreme care. Most of the holes were rough with slightly chipped edges. I figured a little bit of round needle filing would smooth them up a little bit making the final appearance more finished. I don’t think it made as much of a difference as I thought it would. Here are the before (left) and after (right) photos of the rim:

I then began the task of cleaning out the shank. The shank like the rest of the pipe was quite clean. I used cotton swabs soaked in 99% ethyl alcohol. The first couple came out as you would expect. The tars that had accumulated were quickly removed and the whole stummel had no old tobacco smoke aroma.

I turned my attention to the stem. The stem had obviously spent a good deal of time in someone’s mouth. There was teeth chatter, calcium deposits and an oxidation pattern suggesting frequent use. There were no deep dents

indicative of long periods of rough physical work while clinching a pipe between the teeth. I started imagining the owner of this Doodler sitting after dinner reading his paper while watching Leave It to Beaver, The Donna Reed Show, and The Adventures of Ozzie and Harriet. Before going off to bed he would tap the bowl on a cork knob in his ashtray then run a pipe cleaner or two through the stem. He would then carefully place his smoking buddy on a pipe rack and head to bed.

I used 0000 steel wool to rub away the calcium deposits and remove some of the worst oxidation. I then took the stem to the Deoxidizer solution. I ran a pipe cleaner into the stem from the tenon and left 3 inches to hang the stem from the edge of the jar. I figured that I would hang the stem in the solution for an hour or so.

Sidenote: I think that I have been remiss in explaining the source of the Deoxidizing solution. I use Before and After Extra Strength Deoxidizer from https://www.lbepen.com/shop-5. They have remarkable products mainly for the restoration of fountain pens. I am also a big fan of their Before and After Restoration Balm (for the briar), Before and After Fine and Extra Fine Polish (for stems).

While the stem was in the Deoxidizing solution I returned to the stummel. You may have noticed a slight crack on the top of the shank.

I worried that this might be a more significant issue and the stummel got all cleaned-up. I moistened a make-up removal pad with 99% ethyl alcohol and began to give the stummel a good alcohol scrub. The only thing that came off the stummel was a little bit of what appeared to be stain. It was very light and its absence did not seem to change the color of the briar. There was no finish to be observed. Bless you Mr. Mincer for not using a lacquer. The crack that looked so ominous when it was dirty, now appeared to be completely superficial. There were a couple of dents along the top of the shank. I decided not to fill these as I thought they went with the rough carved heel of the pipe and I really do not like to do fills.

I started the sanding/micro-mesh process with 400 wet/dry sandpaper wet with a few drops of water being very cautious near the stampings. After the light sanding I wiped the stummel with a make-up pad moistened with the 99% ethyl alcohol. I continued to use the 1500 and 1800 micro-mesh pad also wet with the alcohol wipe between micro-mesh pads. The 2200-12000 micro-mesh pads followed again with an alcohol wipe between each pad. When finished I gave the stummel a coating of Before and After Restoration Balm with my finger and thumb. I then switched to a baby toothbrush with Restoration Balm to work the balm into all the holes, rings and carvings. The stummel was then set aside to allow the balm to do its thing.

After about an hour I returned to the stem. I lifted it from the Deoxidizing solution and allowed it to drip most of the excess back into the jar. Nitrile gloves are recommended when handling the Deoxidizing solution. I then use a more coarse cotton shop rag to wipe the solution from the stem. It starts out feeling kind of tacky but as you rub the rag absorbs the solution and buffs away the oxidized vulcanite. I rub quite vigorously until the stem feels smooth and dry in the rag. After the outside of the stem was rid of the solution I used two absorbent pipe cleaners to run through the airway of the stem. Immediately after the deoxidizing solution is removed I dip my finger into mineral oil and give the stem a complete coating of oil. I then dip a pipe cleaner in the oil and run it through the airway.

The stem was ready for sanding, micro-mesh pads and polishing. The stem had no deep tooth chatter or bite marks. I was able to lightly sand with 400 wet sandpaper to remove the chatter quickly. The stem was then wiped with a layer of Obsidian Oil from my fingers and wiped off with a clean make-up pad. I then started the micro-mesh pads 1500 (wet) and 1800 (wet). Between each pad I reapplied a light coat of Obsidian Oil and wiped it off with a make-up pad. Those were followed with the remaining sequence of micro-mesh pads 2400-12000 with the same oiling and wiping between pads.

Overall I was very pleased to have been able to restore a piece of pipe

smoking history to its glory. It really is a strangely beautiful pipe. I don’t recall where but, I do remember reading that the whole Doodler rings and holes thing doesn’t really work. I have yet to try the old girl out. She has a place with a few other oddities of history up on the mantle. Thank you for reading the ramblings of an old pipe lover. If you like this restoration stuff please click the like and subscribe buttons.

Below are photos of the finished Doodler.