Photographed and written by

John M. Young

My Peterson Pipe Acquisition Disorder (PPAD) has come out of remittance and I have experienced an attack. Then again it was fully expected. I can’t run around with a name like NebraskaPeteGeek and not have full blown PPAD at least semiannually. The lovely 606 in the photo above did not arrive like that. It was spotted at an auction on eBay a couple of weeks ago. I couldn’t believe my eyes at first. A Peterson Dunmore with a shape other than the 300 System shape was very interesting. I’ll get more into that in the “Background” below.

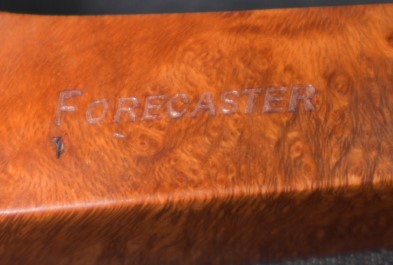

This pipe has Peterson’s over “DUNMORE” on the left, the Peterson P on the stem and MADE IN THE over REPUBLIC over OF IRELAND and 606 on the right. There is also a beaded edge at the shank end, a characteristic of the Dunmore line. When the pipe arrived it appeared in the photos below.

Background

As much as I love the history of the Kapp and Peterson company and Peterson pipes, I will not get into that other than give you resources to read the history for yourself. I will delve into the Dunmore, or Dunmoor line of pipes at greater depth.

For a great history Mark Irwin and Gary Marlburg’s book is a must read for a Pete Geek.

(Available at https://www.smokingpipes.com/accessories/books/moreinfo.cfm?product_id=471478) Given the price is a bit high but worth every penny for a Peterson aficionado.

The next site is pipedia.org’s History of Peterson by Jim Lilley (Peterson – Pipedia)

Lastly the pipephil.eu site for all things logo: Peterson: historical pipes — Pipes: Logos & Markings (pipephil.eu) They also have a few other links to things like the Peterson timeline and P-lip information.

Now to the stuff regarding this pipe: A Peterson Dunmore. I refer to Mark Irwin again here and his blog, Peterson Pipe Notes. I can wholeheartedly recommend the free at

https://petersonpipenotes.org/ Yes, you will get emails but only for things like the weekly blog post and occasional Peterson pipe drops (like the Peterson Pipe Notes Pipe of the Year) or offers for cool Pete Geek merchandise. Anyway Mark has an article on the Dunmore line that is great. https://petersonpipenotes.org/226-documenting-the-dunmore-system-and-classic-lines/

I will include the text here in it’s entirety but recommend the link for the photos. This is used with permission of the author (thank you Mark).

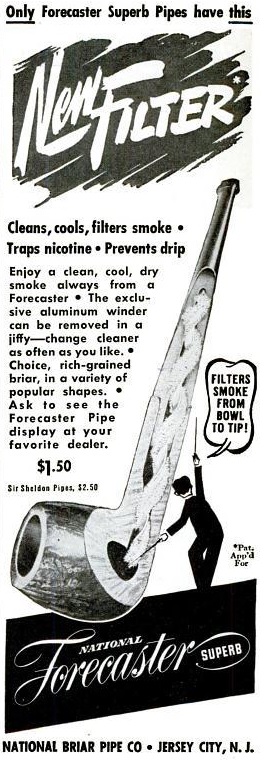

“226. Documenting the Dunmore System and Classic Lines

Milos “Mike” Bera at PipesPens&More.com on eBay recently wrote me to say that he’d run across two examples of a Peterson Dunmore Classic line he’d never seen before—a higher-grade line with a briar-in-brass sandwich band. As I thought they were not only gorgeous but undocumented, the time seemed right to take a look back at the history of the Dunmore System and Classic lines.

I’ve been a fan of the Dunmore lines since I first saw them through the case back in the late 1980s and had to have one, a fat-bottom 72 (the 302 equivalent). Like everyone else, I thought there was some kind of mistake—“Where’s the nickel mount?” I remember asking. But the Dunmore System set out to be something a little different, yet within the classic Kapp & Peterson house style.

The line originated in collaboration with Iwan Reis in 1971. How it came about is anyone’s guess at this point. Chuck Levi, the man who more than any other was responsible for bringing the great Danish artisan pipes to the US, was working with the creative minds at K&P to bring something new to the IRC catalog, and this was one of about a dozen K&P lines that debuted as exclusives in the Iwan Reis catalogs of that era.

The concept was to modernize the System pipe by removing what was perceived as the old-fashioned nickel mount. And old-fashioned it was—if you look at pipe catalogs from the 1940s on through most of the rest of the 20th century, nickel ferrules and even bands were almost non-existent. K&P was virtually the only hold out, using sterling bands on the Sterling Silver Classic line and on the Premier & De Luxe Systems. A bead was then carved around the stummel at the mortise end. As you can see from the IRC detail, sometimes the contrast stain made the beads stand out, and sometimes not.

But there were two more ingredients to the original Dunmore aesthetic which can be seen the photo below. Paddy Larrigan, K&P’s master-craftsman, was always striving to push the envelope in pipe engineering, and one of the things he dearly loved was a pipe that would sit, so he shaved off the bottom of the shank to allow the Dunmore System to sit on its shank and button, which gives it its uniqueness in the catalog. The downside of this is that I am not convinced that all the Dunmore reservoirs, being slightly smaller than the traditional System, are quite as effective.

The third distinguishing mark of the original Dunmore lines is the stem. Both the System and Classic versions utilized the wide-shoulder “Comfort Lip,” with a painted gold P on the stem. This doubtless helps the System sit as well as giving it a more muscular visual balance, strength being a long-standing concept in the design language of the company. While it gives the illusion of being an army “push” mount, of course it isn’t, but is a traditional tenon-mortise or “navy mount” as the old hands at K&P used to call it.

The 1971 IRC catalog description reads, “dunmoor briar IRC ’71 modern system without sterling band, natural $12.00.” This intentional misspelling of “Dunmore” would persist through subsequent IRC catalogs, the copy-writer evidently under the spell of e.e. cummings and favoring an English flavor to his pipes. The name, like almost all K&P line names, is taken from the Irish landscape, in this case the town in County Galway famous for Dunmore Castle.

The 1975 Orange Catalog shows the initial Dunmore System release was in only seven shapes:

This was later expanded to include both the original bent dublin shape 5 (75) and XL5 (XL75) and the replacement calabash shape 5 and XL5. The remaining “new” System shapes were also added to the Dunmore lineup, the 01 becoming the Dunmore 73, the 02 the 70 and the 03 the 76. The fact that the 304 and 306 “setters” introduced in 1984 never entered the Dunmore System lineup adds the probability that the line had been discontinued by then.

The smooth Dunmore System features a light brown natural finish, sometimes occurring with broad flames, as can be seen in these photos of an unsmoked 77 System:

The rusticated version of the Dunmore System seems to have been finished in at least two techniques or versions. Neither is as deep as the Pebble Rustic finish but they still feel very therapeutic under thumb and finger.

Even when we were beginning our research on the Peterson book (due out in reprint later this year), most Pete fans had no idea there was also a Dunmore Classics line featuring the same beading at the mortise and wide Comfort Lip mouthpiece. Documentary proof was found in the rare 1978-79 Peterson-Glass catalog:

The Dunmore System and Classic Lines from the 1978-79 Peterson-Glass Catalog

I don’t know whether the Dunmore Classics was a short-lived line or whether it was primarily available in Europe, but it almost never appears on the estate market here in the US. As you can see from the catalog and the 406 pictured above, the same aesthetic was followed for the Classic line—light brown, nearly natural, higher-quality smooth bowl (or dark rustic) and faux army mount with gold-painted P, wide saddle and P-Lip stem. Only the Dunmore System, as far as I have been able to document, had the flattened stummel allowing it to set.

I have always hoped to run across an unsmoked rustic Dunmore System with the dark contrast stains seen in the Peterson-Glass catalog. I wonder if this finish actually went into production, because the ones I’ve seen all look more-or-less like the XL75 shown above.

The original Dunmore lines seemed to have been dropped at about the time the company went through its worst redundancy in 1984, as there are no more traces of it in the company’s ephemera from 1983 on. I remember the proprietor of my B&M, Cavalier Pipe & Tobacco in Barracks Road Shopping Center in Charlottesville, telling me when I bought my shape 73 Dunmore that the line was out of production, so I’d better get it if I wanted it (don’t you miss high-pressure salesmen?)—and that would have been 1986 or ’87.

The second iteration of the Dunmore Classics line is that recently discovered by Mike at PipesPens&More on eBay. I would tentatively date it to c. 1995, well after K&P had gotten on its feet again and was doing some new and fascinating things. It seems to belong with three other briar adornment lines from the same period: Paddy Larrigan’s Briar in a Circle Systems and the Galway and Kapp-Royal higher-grade lines with their wonderful inset briar rings.

Mike’s Dunmore Classics line is certainly on a par, from the two examples he’s found, with the Galway and Kapp Royal briars and maybe better, although probably not as fine as the Briar in a Circle Systems. Take a closer look at this 80S, which Mike sold within 24 hours of posting it on eBay:

The last Dunmore Classics line made a brief appearance in the Dublin era’s second decade, somewhere in the 2000s, probably around 2005 or so. Jim Lilley’s old blog site made a reference to them, and I remember seeing them for sale at internet shops.

I know it appeared well before I got interested in writing the Peterson book, because I don’t have any internet images of it in my files. These photos of the B5 and B11 give a good idea of what the line was like, although it appears to have begun in a higher range and then slipped to a lower.

Updated Identification Guide

Dunmore (1971–c. 1984; c. 1995; 2006–2010) Appeared in 1971 as Iwan Reis & Co. exclusive line “Dunmoor,” Premier-grade unmounted System in smooth natural or rustic dark chocolate contrast in all shapes, with beading at the shank, faux wide-saddle P-Lip with gold paint P. Documented in Associated Imports catalog from 1973. Classic Range line from 1978 with same faux army mount and finishes. Second scarce Classic Range line, c. 1990, higher-grade smooth bowl with brass sandwich and briar band, P-Lip. A third Classic Range line, 2006–2010, mid-grade, featured standard and some B shapes, with beading around bowl instead of shank-face, for European market.

Many thanks to Mike Bera

Photos of the Dunmore 80s and 68 courtesy Mike’s Pipes Pens & More

Photos of the B5 and 406 Dunmore courtesy Smokingpipes.com” (https://petersonpipenotes.org/226-documenting-the-dunmore-system-and-classic-lines/)

With that information at hand I can date this Peterson Dunmore with a good deal of certainty. The 606 shape is of the “Classic Range line” thus from 1978-1984. A mere 6 year window.

The Restoration

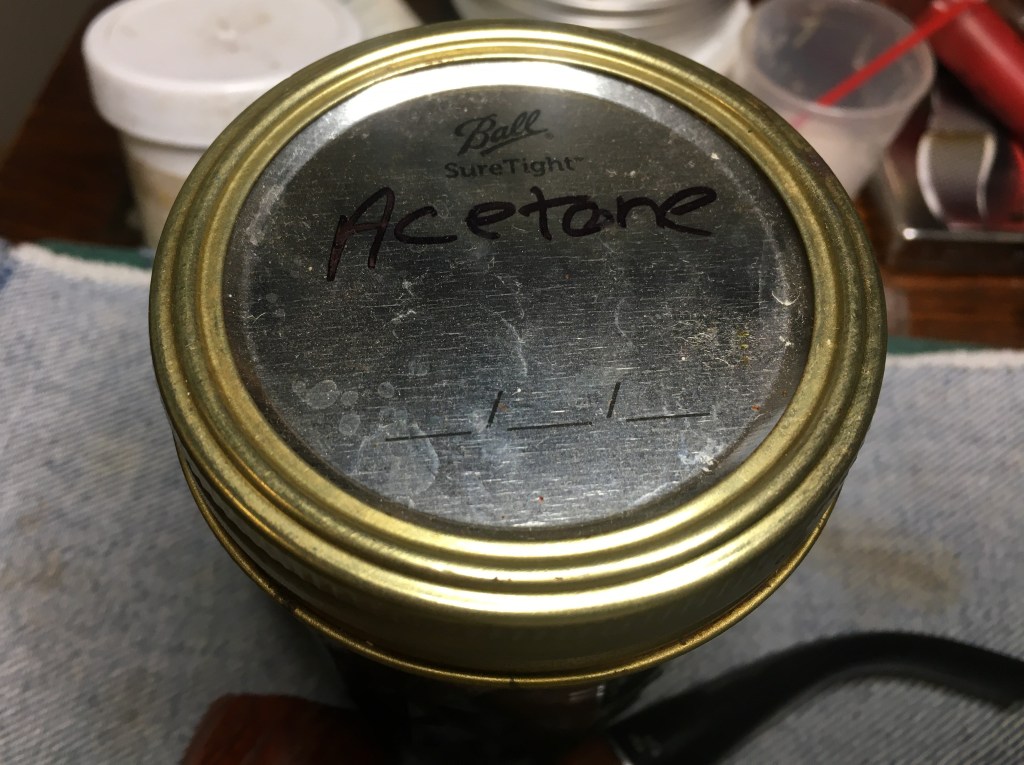

There is a clean denim piece for a work surface so, it must be time to start another project.

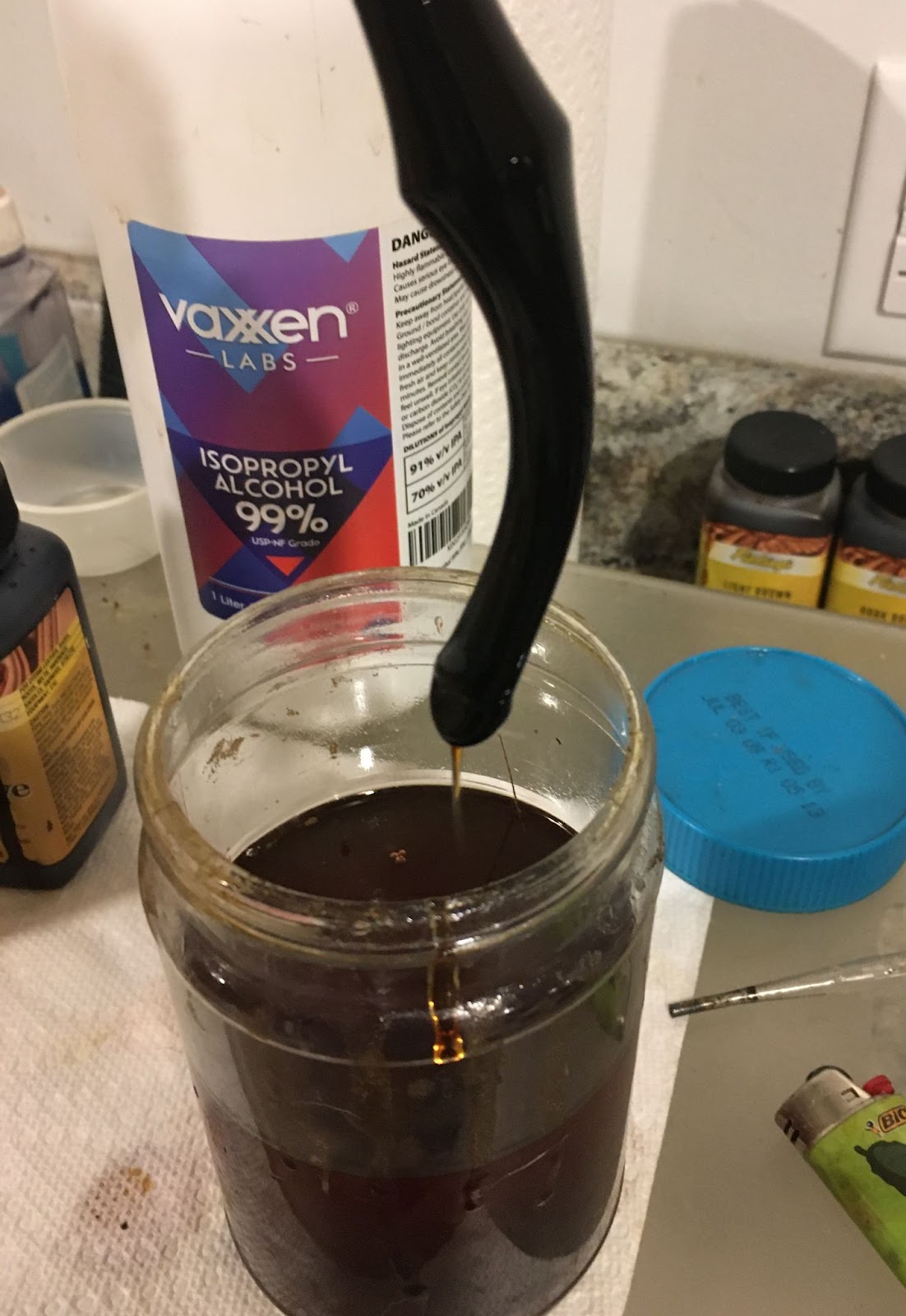

The stem was the part of this that needed the most attention and it went into the OxyClean solution first.

The reaming tools were gathered. The PipNet with its #2 and #3 blades for this nice wide chamber would see some action.

The reaming started easy with the PipNet and the #2 blades. The the #3 blades were a tight fit and required some scraping with both scrapers to allow it access to the tobacco chamber. Eventually the chamber was reamed and sanded with 220 sandpaper wrapped around a wood dowel. I finish sanded with 320 sandpaper and my finger. The chamber looked great with no signs of any damage.

The chamber may look good but the rim was lava encrusted.

Saliva and a sharp knife were used to scrape the rim.

The stummel then made its way to the sink for a scrub with undiluted Murphy Oil Soap and a medium bristle toothbrush. The soap was rinsed with warm water and the stummel dried with a cotton hand towel.

Returning to the workbench the stummel looked much better.

A quick wipe with a make-up pad dipped in 95% ethyl alcohol to make sure there was no remaining wax or finish remaining was done. This produced some color on the pad but I think it was just dirty old wax and maybe a bit of stain.

I did see a few pits that would require filling with cyanoacrylate (CA, super glue) and briar dust.

I turned my attention to cleaning out the airway within the shank. I used a couple of alcohol soaked cotton swabs to soften the old smoking residues in the airway. I then poured 3-4 ml of 95% ethyl alcohol into the bowl and allowed it to flow into but not through the shank. I used a nylon shank brush to scrub the airway with the alcohol. The alcohol was poured into a medicine cup to assess the dirtiness of the airway. Not bad but still quite a bit of cleaning and repealed alcohol scrubs. Oh yeah, folded bristle pipe cleaners were also used to scrub with. Numerous more cotton swabs, folded pipe cleaners and a few ml of ethyl alcohol later the shank was clean.

The stem came out of the Oxy bath and was vigorously wiped with a dry make-up pad. The pad was heavily stained with oxidized rubber.

Several more make-up pads with SoftScrub were used to try to remove the stubborn oxidation. Adjectives other than “stubborn” may have been uttered during this process.

I oiled the stem and left it for 24 hours. The next day I returned and used SoftScrub again to remove the oil. Well, more than oil came off.

Back into the Oxy bath went the stem. It was there for another hour.

I turned my attention to filling the pits. A small drop of brown CA was applied to the pit and a small scoop of briar dust was then placed onto the wet CA and pressed into the pit. The excess briar dust was brushed off with a bristle pipe cleaner. This was repeated for each of the fills. The CA and briar dust set-up very quickly and were filed with a flat needle file then sanded with a 400 grit sanding sponge.

The stummel was then sanded with a series of sanding sponges from 600-3500 grit, in sequence. Between each sponge the stummel was wiped with an alcohol moistened make-up pad.

The stummel was then worked with a series of micro-mesh pads 4000-12000 grit. Between each pad the stummel was wiped with a make-up pad dipped in alcohol.

The stummel then was coated with Before and After Restoration Balm and allowed to sit for 30 minutes.

The stem was retrieved from the Oxy bath for the second time. And wiped with a dry make-up pad. This time much less oxidized rubber came off of the stem.

The stem was sanded with a series of sanding sponges from 600-3500. Between sponges I would rub a small drop of mineral oil onto the stem and wipe it with a paper towel. This was followed by the micro-mesh pads 4000-12000. Between the pads I applied a drop of Obsidian Oil to the stem, rubbed it onto the surface and wiped with a paper towel. I failed to photograph any of the stem sanding and micro-meshing, sorry if you were looking forward to that.

The stummel was wiped clean of any remaining Restoration Balm with an inside out athletic sock.

I debated showing this next step as it was a mistake. Since I am rather adept at making mistakes I thought I’d show you what not to do. I thought the Peterson P logo on the stem should be repainted in white. I cleaned the surface with a cotton swab and 95% ethyl alcohol and gave it a coating of white acrylic model paint.

While the paint was still slightly pliable I scraped the high spots of the logo with a plastic card and wiped away any paint from around the logo.

I then proceeded to wax the pipe with the buffer and carnauba wax and do the “finished” photographs. It wasn’t until I was refreshing my memory and writing the background section that I came across the “P-Lip with gold paint P” from Mark Irwin’s Peterson Pipe Notes dunmore description. Well the white P just wouldn’t do. Back to the workbench, I recleaned the white acrylic paint from the logo using the ethyl alcohol and a cotton swab.

I then made an applicator for the gold Rub’nBuff from the plastic tube of a cotton swab. I cut one end from the tube, heated the plastic with a lighter and flattened the hot plastic with a knife blade.

I used scissors to cut the flattened plastic into a micro-spatula type device.

The gold Rub’nBuff was applied with the plastic tool. The excess gold was wiped onto the denim. I let the gold Rub’nBuff dry for a minute of two and used the tool to scrape away the excess gold from around the logo. The area was then hand buffed with a soft cotton cloth.

There, that’s more like it and correct. Living and learning. I hope my mistakes help you to avoid making some of your own.

The pipe went back to the buffer for a touch-up re-waxing with carnauba. Then back to taking the real finished photos.

Overall this Peterson Dunmore 606 Pot turned out pretty well. I have to admit to not being happy with the finish of the stem. The oxidation was deep into the vulcanite. Even after the Oxy baths, SoftScrub and sanding it can still be seen. Given under normal light conditions the stem looks fine, bright light makes the oxidation stand out. I did not want to use the Before and After Deoxidizing solution for fear of losing the logo. That may be the only way to address the issue short of sanding the entire stem and losing the logo to that. This will be a personal pipe for the time being. Unless someone really wants it and makes me an offer I can’t refuse. The briar of the 606 is lovely, showing off Peterson’s Premier-grade and I was able to keep the original stain without altering it. Of the areas that I filled I think only one was a flaw in the briar and the others were dings from use. The very nature of the Dunmore non-System shape is a rarity and a pretty rarity at that. The dimensions of the Peterson Dunmore 606 Pot are:

Length: 6.21 in./ 157.73 mm.

Weight: 1.44 oz./ 41.00 g.

Bowl Height: 1.65 in./ 41.91 mm.

Chamber Depth: 1.36 in./ 34.54 mm.

Chamber Diameter: 0.82 in./ 20.83 mm.

Outside Diameter: 1.58 in./ 40.13 mm.

I do hope that you have found something here useful to your own pipe care, maintenance or restorations. If you like this sort of thing, please click the like and subscribe buttons. Thank you for reading the ramblings of an old pipe lover.

Below are some photos of the finished Peterson Dunmore 606 Pot.

Oops, there is a finished photo showing the white logo. Darn lazy, I say.

There’s another white logo. Why do you keep reading stuff by this guy?