Photographed and written by

John M. Young

I first laid eyes and hands on a Rettke pipe in July of 2025. You can see that entire restoration here. I was taken by the rather nontraditional, double drilled shank, of the pipe. These pipes are what I call “gimmick pipes”. Now, not all gimmicks are equal. I am sure that Charles Peterson was considered a gimmick pipe maker with his three patents for the Peterson system back in the late 1890s. That gimmick has been used to great result and success for well over 125 years.I made an offer to the seller and was turned down. The pipe sat through several auction cycles and remained unsold. I made a lesser offer and it was accepted. The virtue of patience strikes again. The pipe did not have far to travel after the purchase, merely from Washington, Missouri to the wilds of southeast Nebraska. Yes, the same Washington, Missouri as both the home of J. Rettke and Missouri Meerschaum pipes. Below are some photos taken before I began working on the pipe.

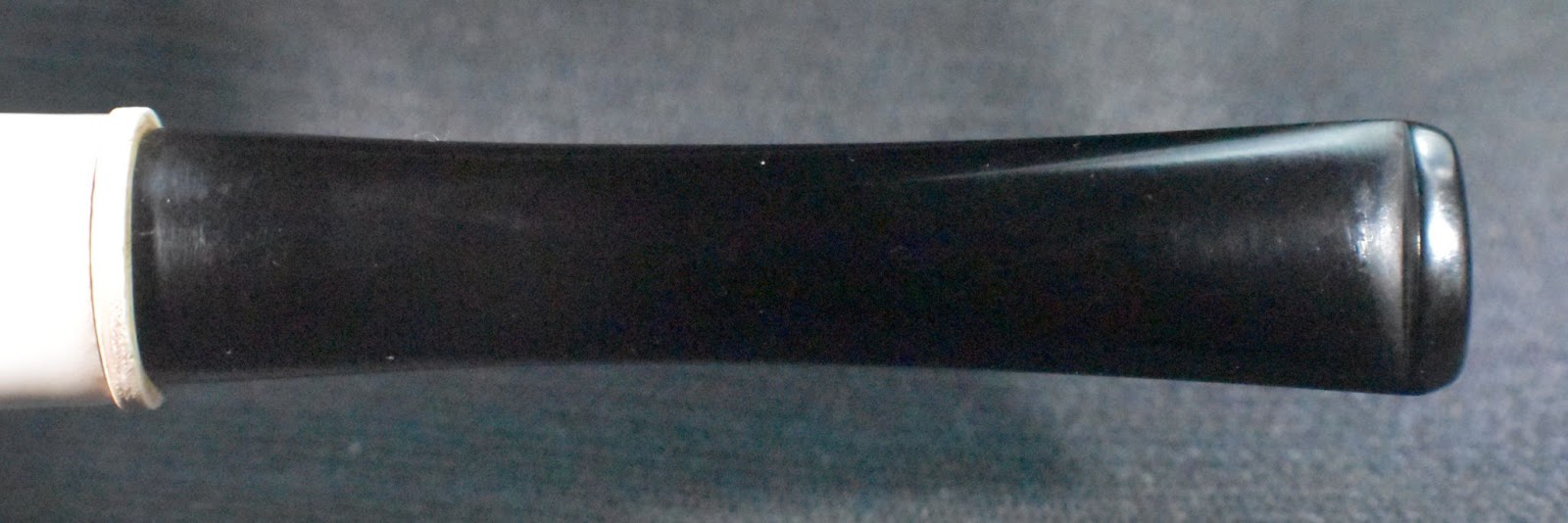

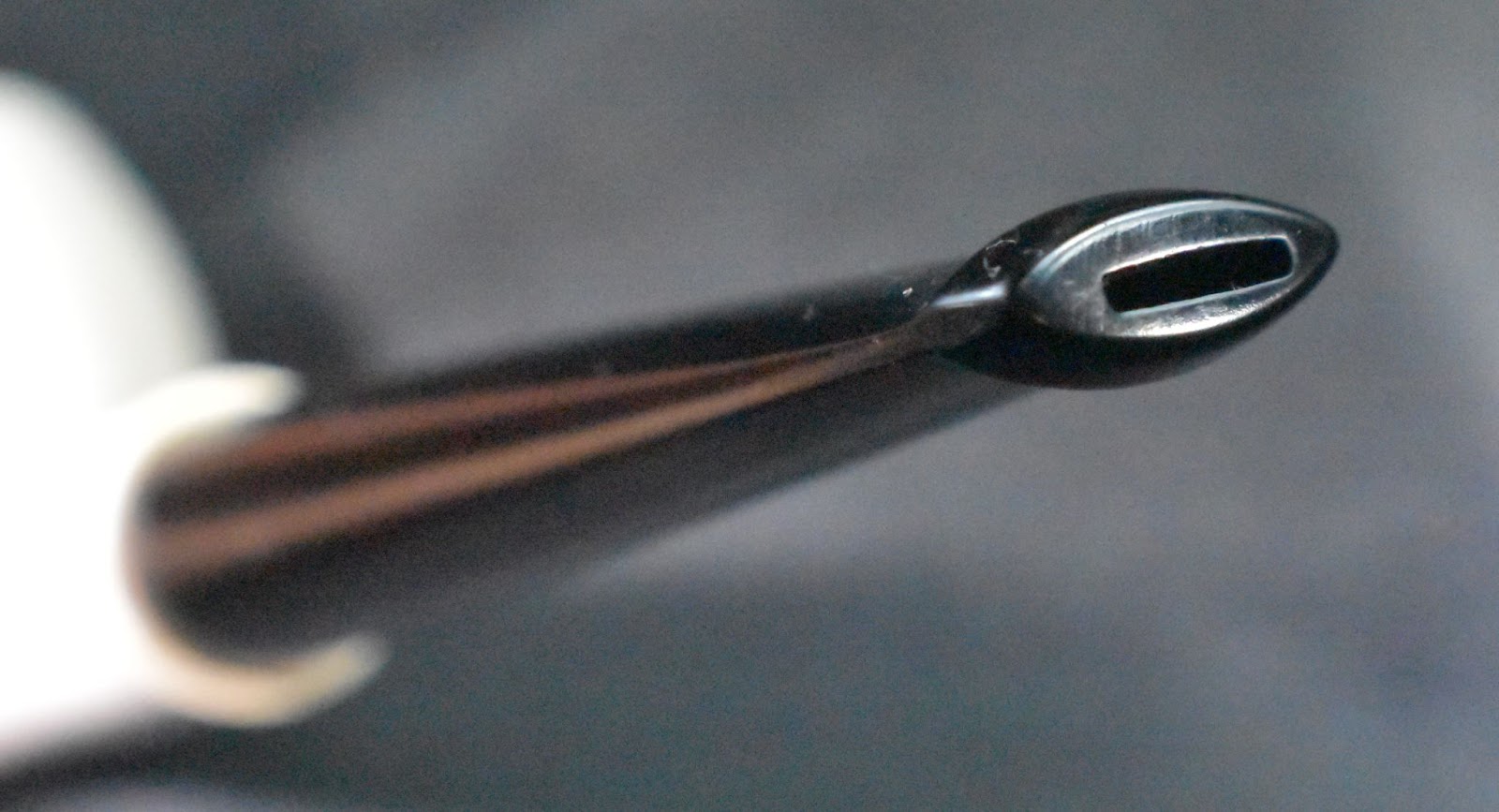

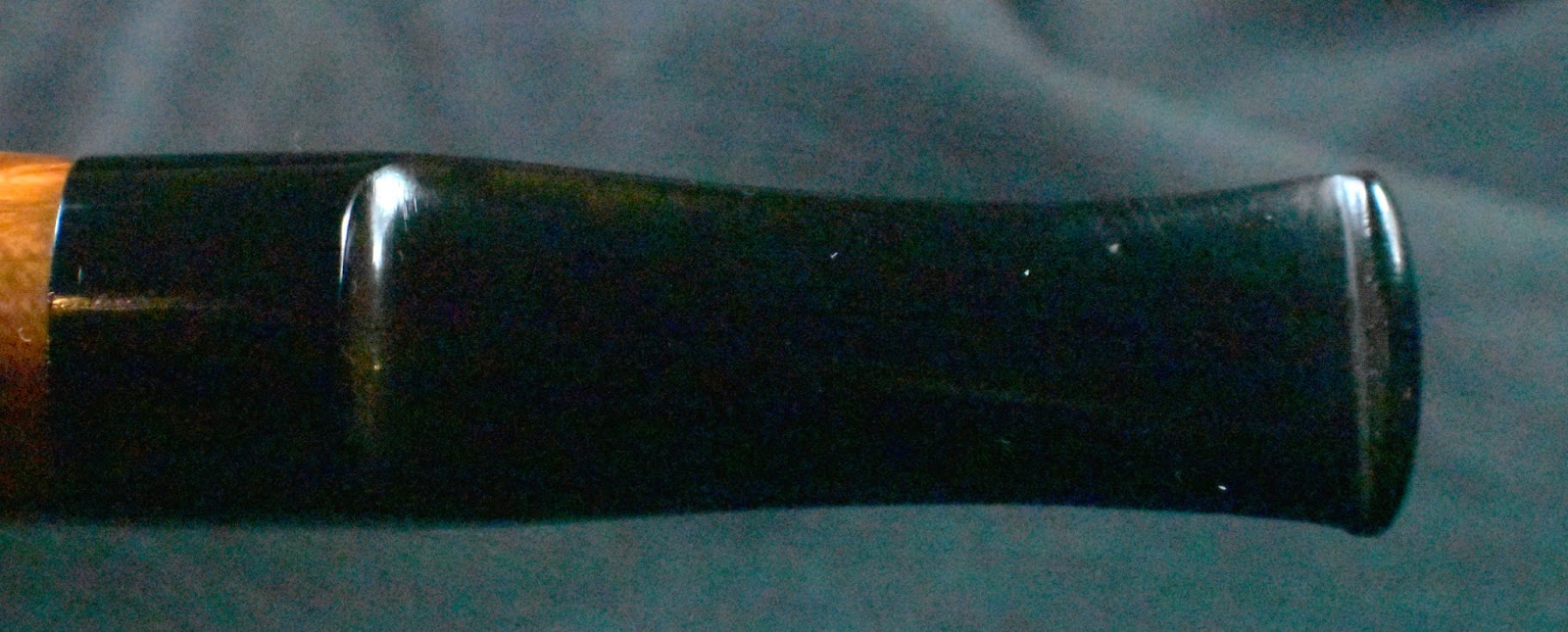

Overall a pretty clean specimen with no glaring issues. The stem had oxidation expected of a 60+ year old pipe. The internals looked clean. There were no obvious fills, indicating a good quality briar. The grain of this pipe was not as distinctive as the first Rettke I restored and I thought that maybe a contrast dye would bring out the existing grain. The rubber seal/end of the “whirler” ( J. Rettke’s term for the spiral aluminum condenser) showed signs of drying and oxidation and may need to be addressed or replaced. Otherwise a thorough cleaning was in order.

Background

I will use the same Background information that I used for the first Rettke restoration and include it here in its entirety:

“I started my research on Rettke pipes with a pipedia.org search on “rettke”. Below is the short entry from that site.

“J. Rettke, Washington MO, PAT. June 12 1962. The silver colored thumbscrew below the stem unscrews and is a 2⅜” corkscrew like device. The company is now gone having been purchased by Missouri Meerschaum. This odd looking pipe is made of briar and has a lower chamber with a metal condenser and an upper chamber that contains a filter. The smoke leaves the bowl thru the lower chamber then into the upper and out the stem. It smokes dry and cool. It has a large bowl.”

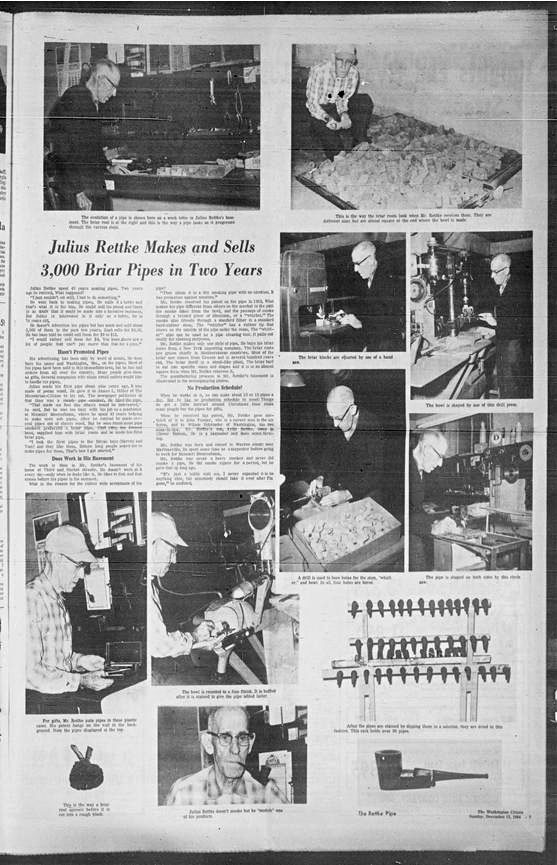

(Rettke – Pipedia) I could not read the above newspaper article even by zooming in.

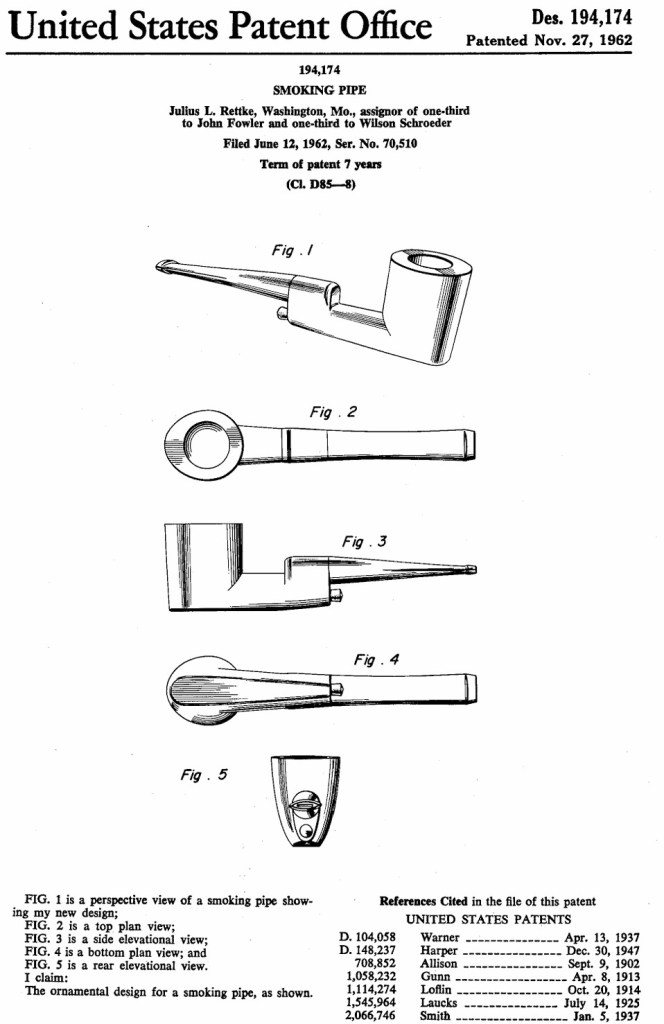

The next search was using Google patent and searching for “Rettke 1962”. This search turned up the original patent diagrams:

(1498404097506821639-D0194174)

My next search was for Steve Laug’s Rebornpipes.com. Steve Laug did a Rettke restoration back in 2017 and contained links to the State Historical Society of Missouri. I could not get this site to produce the same document or to even display the link Mr. Laug has in his blog post. I will link Steve Laug’s blog here: Restoring a J. Rettke Patent Pipe from Washington, Missouri | rebornpipes. It is a very well written and researched piece that does contain a transcript of the newspaper article as well as several photographs of Julius Rettke and the pipe making process.

My favorite quotes from the newspaper article are,

“The work is done in Mr. Rettke’s basement of his home at Third and Market streets. He doesn’t work at it every day only when he feels like it. He likes to fish and that comes before his pipes in the summer.”

I can completely understand the lack of enthusiasm for pipe work when fishing is taking a priority.

And this quote:

“Mr. Rettke received his patent on his pipe in 1962. What makes his pipe different from others on the market is the path the smoke takes from the bowl, and the passage of smoke through a twisted piece of aluminum, or a “whirler.” The smoke also travels through a standard filter in a standard hard-rubber stem. The “whirler” has a rubber tip that shows on the outside of the pipe under the stem. The “whirler” also can be used as a pipe cleaning tool. It pulls out easily for cleaning purposes.” Here the newspaper article talks about a rubber tipped “whirler”. That is how the whirler of my pipe is made. The other Rettke pipes I saw in photos all had a knurled aluminum tip. This little fact is mostly non-important, I just found it interesting.

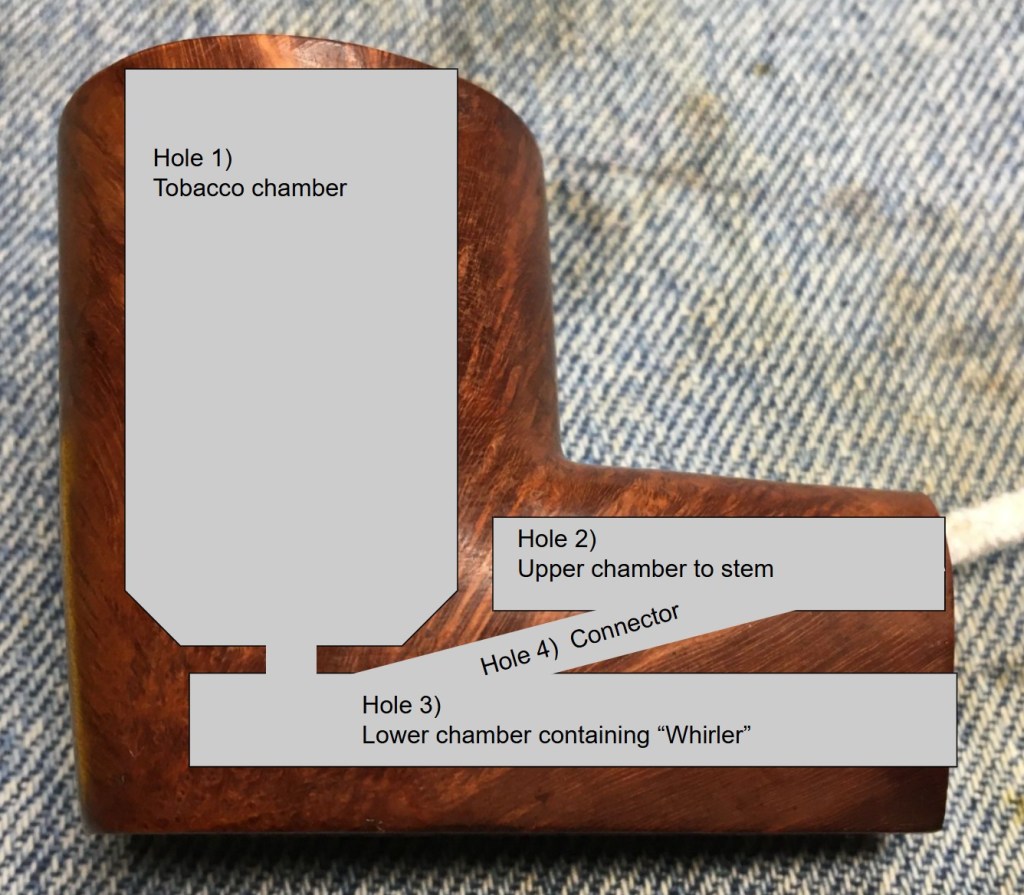

Now for the fun part: How does this pipe work? In the news article transcript it said, “four holes are bored.” under the photo of J. Rettke at the drill press. I read that after I had done my exploration of the stummel and it was in near complete agreement of what I observed.

Using the above photo, I overlaid some image features to indicate the “four” drillings.

Not to be a smart ass, but I think Mr. Rettke would agree that there were actually 5 drillings. The final hole would be a hole at the bottom of the tobacco chamber connecting the airway to the lower chamber. I’ll blame the reporter for the oversight and not Mr. Rettke.” (A Rettke Pipe Restoration for the Real American Pipe Smokers (RAPS) Facebook group – NebraskaPeteGeek)

The Restoration

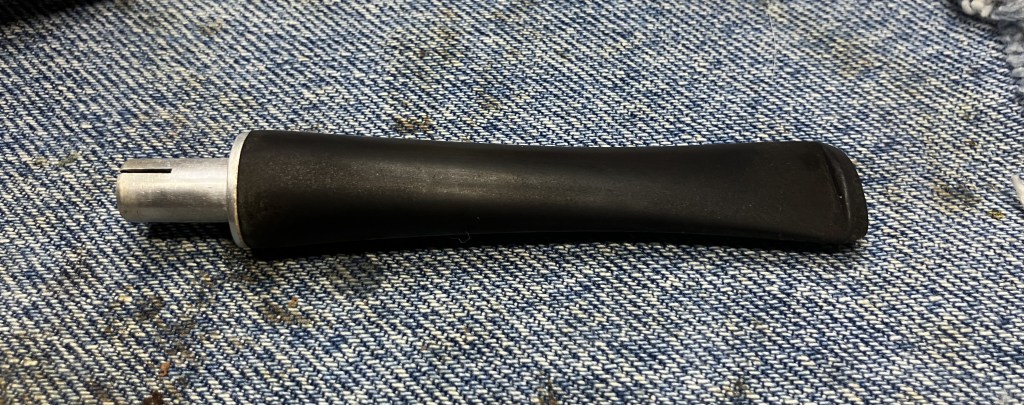

This pipe landed on the workbench and a cleaned denim piece.

I decided to work on the whirler first.

The rubber was dried and cracked. I hoped this was only on the surface.

The rubber was coated with Mark Hoover’s Before and After Hard Rubber Balm. Mark was kind enough to send me a bottle of this product to test. I doubt that he ever imagined it to be used on a Rettke whirler but hey, it is rubber. The whirler was set aside to allow the balm to work it’s magic.

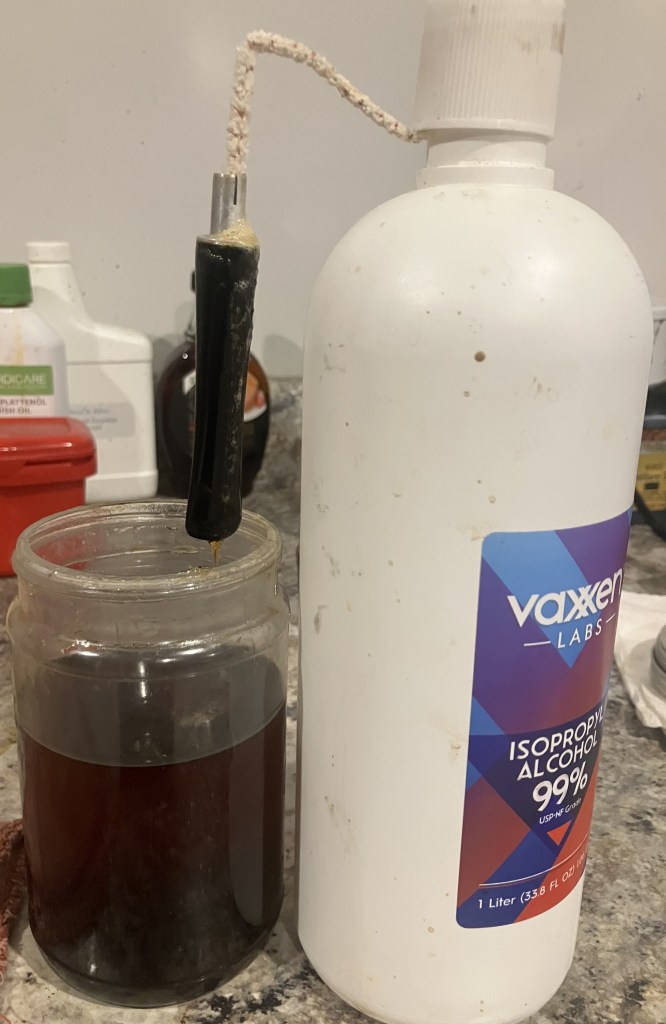

The stem was cleaned with several cotton swabs and pipe cleaners dipped in 99% ethyl alcohol. The stem appeared to have been used without a Medico filter.

After numerous cotton swabs, I took the stem to the sink for a scrubbing with Castile soap and a nylon brush. The soap was used undiluted and as the photo below shows the brush came back with a good deal of smoking residue.

After the stem was rinsed with warm water, I returned to the workbench and found the cotton swab dipped in alcohol started coming back with far less color. Victory!

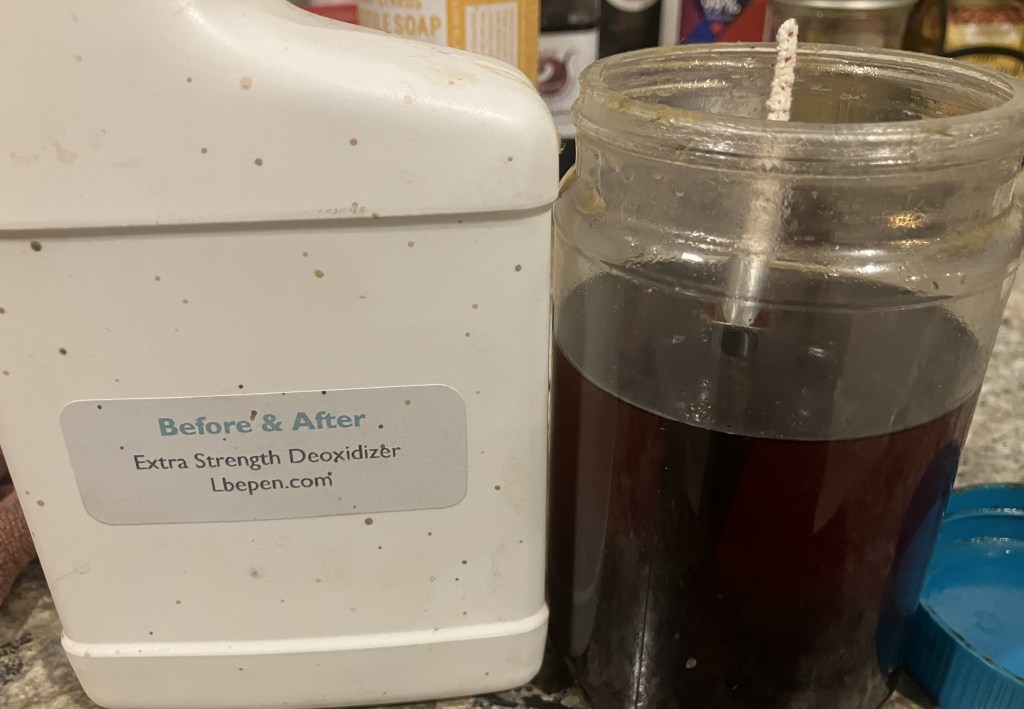

Once clean, the stem was suspended into a solution of Before and After Extra Strength Deoxidizer. I ended up leaving the stem in the solution for a bit over 24 hours. The following day was Christmas Eve and I was away from home for the day.

The reaming gear was gathered.

The PipNet with the #2 and #3 blades did most of the reaming.

Some light clean-up scraping was done with the General triangular scraper.

The below photo is of the reamed tobacco chamber.

The chamber was sanded with 320 sandpaper wrapped around a wood dowel. The bare briar showed no signs of any damage from heat.

The shank cleaning was twice as much work as a normal pipe due to it having twice as many shank draft holes. Weird, eh? Again alcohol dipped cotton swabs and bristle pipe cleaners were used along with a bit of scraping with a dental scraper. The upper chamber returned swabs with less charred residue than the lower chamber.

I thought that an alcohol cotton treatment would be a good idea to fully clean and de-ghost the draft of this pipe. Not that the previous user had used a foul smelling tobacco, it actually was a pleasant burley based aromatic from what my nose could tell. The chambers and passageway was packed with cotton.

Usually a pipe holds around 10 ml of 99% ethyl alcohol. I figured this one might hold a bit more. The alcohol would be applied with a disposable pipette.

The saturated alcohol would be allowed to evaporate overnight. This would dissolve the remaining smoking residues and tar and move them into the cotton as the alcohol evaporated.

With the stem and stummel now occupied with long term waiting procedures, I cleaned up the aluminum of the whirler with 99% ethyl alcohol and cotton swabs.

The next morning I returned to the workbench for a few minutes before heading to the Christmas Eve celebrations. The cotton had picked up the color of deposited tars.

The cotton was removed with tweezers. I again used alcohol dipped cotton swabs and bristle pipe cleaners to repeat the airway cleaning to remove any remaining, now softened, residues.

The next evening, I removed the stem from the deoxidizing solution and used the patented Drip-Dry-O-Matic, okay, it’s not patented. Yet!

The stem was vigorously rubbed with a coarse shop rag to remove remaining solution and some of the softened oxidized rubber.

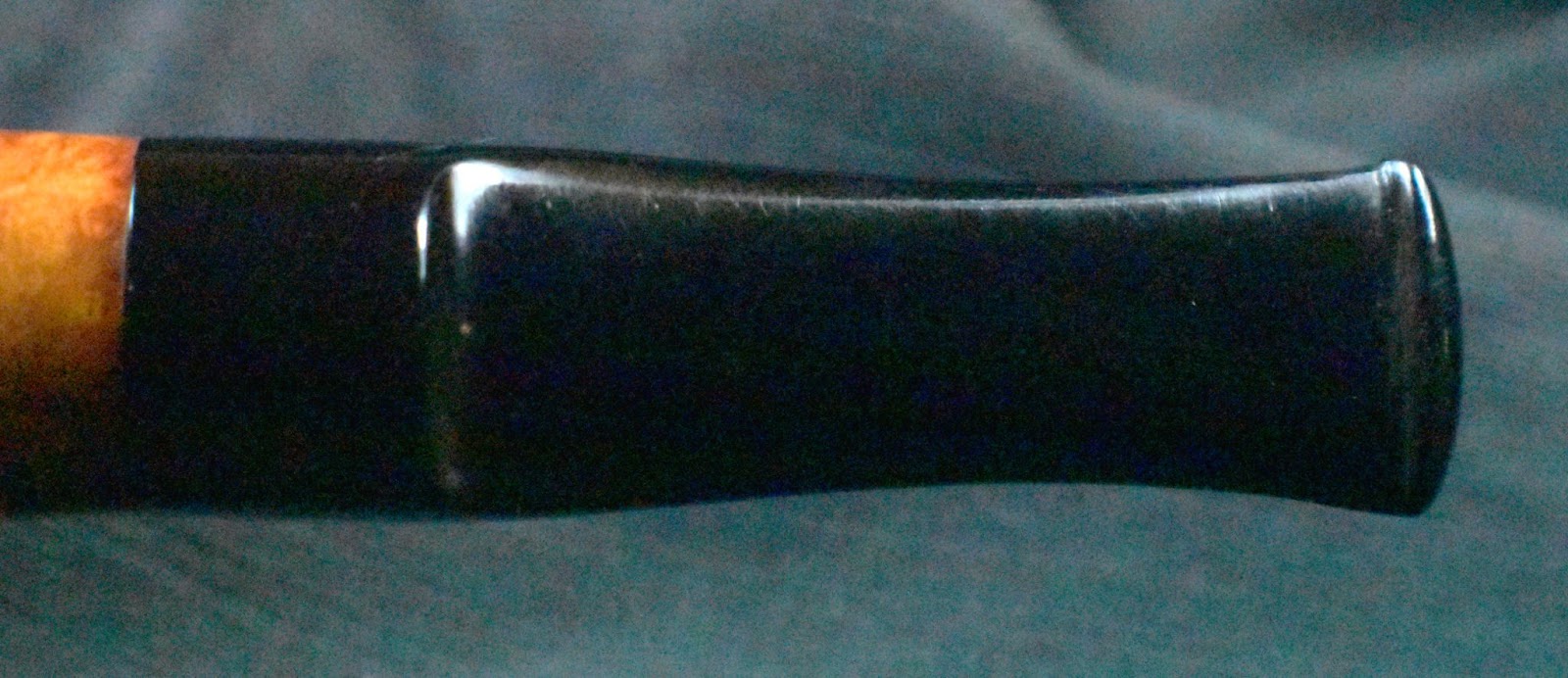

Back at the workbench the stem looked kind of rough but black.

I used some Soft Scrub cleanser of make-up pads to clean off additional oxidized vulcanite.

The stem was then sanded, with more attention on the tooth chatter above the button, with 320-600 grit sanding sponges. Between each sponge the stem was rubbed with mineral oil and wiped with a dry paper towel to remove sanding debris.

It was time to see how a contrast dye would enhance the briar grain. I thought that a base of black with a top coat of Mahogany would look very nice. Both dyes were Fiebing’s Leather Dye applied with a pipe cleaner, flamed with a flighter.

Below you can see the stummel after a coating of the black Fiebing’s. The cork was placed in the tobacco chamber to keep the dye out.

I only wanted the black dye to be absorbed more deeply by the softer grain. I then rinsed the dye from the stummel using 91% isopropyl alcohol over the sink then wiped the stummel with a paper towel.

When sanded with a 400 grit sanding sponge, both harder and softer grain was removed. The dye had penetrated the softer grain deeper than the harder grain.

Next came the mahogany applied with a pipe cleaner.

I again rinsed the dye from the stummel with 91% isopropyl and wiped with a paper towel. Returning to the workbench I sanded the stummel with 400 then 600 grit sanding sponges. Below you can see how the black accentuated the grain and how the mahogany added warmth to the non-blackened areas.

After a drying time of about 30 minutes I applied a coating of Before and After Restoration Balm to the briar and a coating of Before and After Hard rubber Balm to the stem and rubber of the whirler. This was allowed to sit for about an hour.

The balms were hand buffed from the pipe with an inside out athletic sock.

The pipe, both stem and stummel were then buffed with rogue buffing compound at the buffer. The pipe was wiped with an alcohol wetted make-up pad to remove any remaining buffing compound then returned to the buffer for several coats of carnauba wax.

The final step was to hand buff the pipe with a microfiber polish cloth.

After restoring the first J. Rettke pipe, I wrote this sentence in the conclusion. “Of the many gimmick pipes I’ve had the pleasure of working on, I think this one would actually be an effective system for condensing steam. It just makes sense.” I could not have said it better, myself. Wait, I did say it. Anyway, this pipe turned out very well. The contrast dye is what I hope it would look like – greater definition of the briar grain. The stem polished up nicely. I tried the draw both with and without Medico filters and the draw was very good either way. With the first J. Rettke, I ended the conclusion by typing, “I would consider this an artisanal pipe from a time before artisanal was cool.” I couldn’t have said that better, myself. Now for the part I had been looking forward to since I saw the first Rettke, smoking it and seeing firsthand if J. Rettke’s patent was effective or another gimmick. The dimensions of the J. Rettke are:

Length: 5.88 in./ 149.35 mm.

Weight: 1.46 oz./ 41.39 g.

Bowl Height: 1.92 in./ 48.77 mm.

Chamber Depth: 1.42 in./ 36.07 mm.

Chamber Diameter: 0.71 in./ 18.03 mm.

Outside Diameter: 1.41 in./ 35.81 mm.

I do hope that you have found something here useful to your own pipe care, maintenance or restorations. If you like this sort of thing, please click the like and subscribe buttons. Thank you for reading the ramblings of an old pipe lover.

Below are some photos of the finished J. Rettke pipe.