Photographed and written by

John M. Young

I left the style of this pipe blank and only used the shape number for reasons that you will see in a minute. I’ve restored a few GBD pipes over the years but this is the first that I have blogged about. This pipe seems very French or maybe Danish to me. A very nice shape which I would be inclined to describe as a slightly bent billiard. The pipe came in an estate lot which also brought a Jarl (https://wordpress.com/post/scimansays1787.com/6336) a Stanwell (https://wordpress.com/post/scimansays1787.com/6189) and 2 other pipes from Sacramento, California to the wilds of southeast Nebraska. I included the links to the previously restored two pipes.

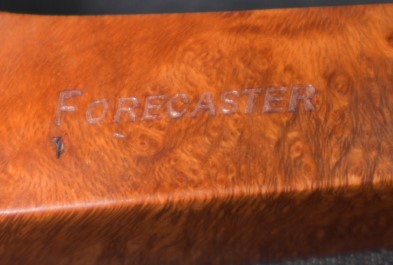

This GBD was in need of some work. As my father used to say, “ Looks like it was rode hard and put away wet”. That phrase was originally intended for horses but dad used it for various things and occasionally women. The stamps were discernible through the grime and read; GBD, within an oval, over SIERRA offset to the right and perpendicular was 1350 over MADE IN FRANCE. The later stamp was quite faint and difficult to make out. Below are photos of the pipe prior to work being done.

The pipe was pretty filthy, the finish was faded, the stem heavily oxidized, bowl caked and the internals were anyones’ guess. This was going to be a fun one. I looked through a few GBD photos and found the below image:

That is the color that I wanted for this pipe. Yeah, I know, I am getting ahead of myself but I heard once that setting goals is important. Though, I think I’ll try to avoid getting dye in the tobacco chamber.

Background

The history of GBD is a long one. I reread the pipedia.org site and realized that including all of that might dissuade some readers from the blog. I will include the first paragraph mainly pertaining to the originators of the company and its name and include the link for those who would like more information.

In 1850 three gentlemen got together in Paris to establish a firm dedicated to the fabrication of Meerschaum pipes – a courageous step in politically restless times. Ganneval probably came from the area of Saint-Claude where he had learned making wooden pipes. Bondier’s family obviously came from Paris and had emigrated in 1789 to Geneva. He himself had worked as a wood turner in the clay and china pipe industry in and around Saint-Claude making stem extensions etc. Donninger was an Austrian or Swiss and had worked in Vienna, the world’s center of the Meerschaum pipe. They agreed on the acronym GBD selecting the initials of their surnames. Bondier survived his partners for nearly 30 years. Their places were taken by others. Hence the property of GBD and therewith the company’s official name changed several times.

- Ganneval, Bondier & Donninger

- Bondier, Ulrich & Cie.

- Bine, Marechal & Cie. and finally

- A. Marechal, Ruchon & Cie.

Meanwhile the GBD name was well established and thus retained. August Marechal and Ferdinand Ruchon led the firm into the 20th century. They were in charge of the company for more than 50 years.” (GBD – Pipedia)

In clicking another link from the above site I came across the following,

“The company was founded in Paris, France in the 19th century by Ganeval, Boundier and Donninger who were no longer associated with the company by the turn of the century. By the time they left the GBD name was well established and thus retained. In 1903 an additional factory was built in England and ran by Oppenheimer. The Paris factory moved to Saint-Claude in 1952. Since 1981 the majority of GBD pipes come from the English factory. At about that same time GBD merged with Comoys, since then all production for both GBD and Comoy comes from a single factory. ( I wasn’t kidding when I said it was brief! )

More history and addition information can be read in the main GBD article.”

(GBD Model Information – Pipedia)

Who doesn’t love a writer with a sense of humor, eh?

Now for the pipe in hand, the GBD Sierra. The stamped shape is a 1305, which according to another pipedia.org page has the following:

(above screenshots from: GBD Shapes/Numbers – Pipedia)

“shapes with an * are non standard bowl shapes, and stem angles with a “rev” conotation refer to pipes with bowls that are canted forward.” (GBD Shapes/Numbers – Pipedia). Now, I personally would not consider this pipe a Dublin nor an apple, I will differ and go with the “apple” designation.

Pepidia.org does have a listing of the models attributed to GBD and their “Seconds”. The Sierra is listed as,

- “Sierra — Rusticated finish, made in France: -”

(GBD Model Information – Pipedia)

Unfortunately, that is all. As for the age of the GBD 1350 apple, I cannot be certain of much other than it was made in France likely after 1970.

The Restoration

As usual I began with a clean denim work surface protection device (AKA a square of old blue jeans).

The stem would need some time soaking in an OxyClean and water solution so that was the first task. I hand buffed the stem with 0000 steel wool to remove the outermost oxidation.

The stem was then placed in the solution and allowed to soak for a couple of hours.

After the reaming the stummel needed to be rid of the years of accumulated grime. It was taken to the sink for a scrub with undiluted Murphy Oil Soap and a couple of different scrub brushes. The first brush was a medium stiff toothbrush. The stummel was rinsed and dried then I scrubbed it again with Murphy’s and a stiffer nylon scrub brush. This too was rinsed with warm water and dried again with a cotton hand towel.

Back at the workbench the stummel was scrubbed agin, this time with the nylon scrub brush and 95% ethyl alcohol.

TO make sure there was no finish remaining I scrubbed the stummel again with acetone and the nylon scrub brush. The stummel was wiped with a make-up pad dipped in acetone as well.

The shank was pretty well tar coated. I scraped with a dental scraper then poured 3-4 ml of 95% ethyl alcohol into the bowl and allowed it to flow into the shank. I then used a nylon shank brush to scrub the airway with the alcohol. I dumped the darkened alcohol into a second medicine cup. The shank brush was wiped on a cotton wash cloth to clean the tar from the bristles and the airway was scrubbed with cotton swabs dipped in additional clean alcohol.

This rotation of scraping, alcohol/shank brush scrubbing, cotton swab scrubbing went on for several rotations until the shank was clean.

The stummel had darkened with all the years worth of wear and tear and my scrubbing so I decided to bleach the briar with a bit of oxalic acid. I used a saturated solution of oxalic acid crystals in distilled water.

The solution was applied with a cotton swab and allowed to sit for 20 minutes.

After the 20 minutes the stummel was rinsed with copious warm water and again scrubbed with the nylon scrub brush, dried with a cotton hand towel and allowed to air dry for 15 minutes. Below is how the stummel looked after all the scrubbing and oxalic acid.

Next it was time for me to see if I could match the red/black dye of the GBD photos from pipedia.org. I gathered the dark red Fiebing’s Leather Dye and other needed gear. I couldn’t find the fishing bobber that I normally use to plug the tobacco chamber and provide a handle so I improvised. A spent 20 gauge shotgun shell fit nicely into the chamber.

The stummel was dyed dark red with the Fiebing’s Leather Dye applied with a folded pipe cleaner.

The dye was flamed with a disposable lighter. I recommend closing your jar of Fiebing’s prior to the flaming. I’ve never had one ignite but it’s probably a good idea to close it anyway.

The stummel was red, very red.

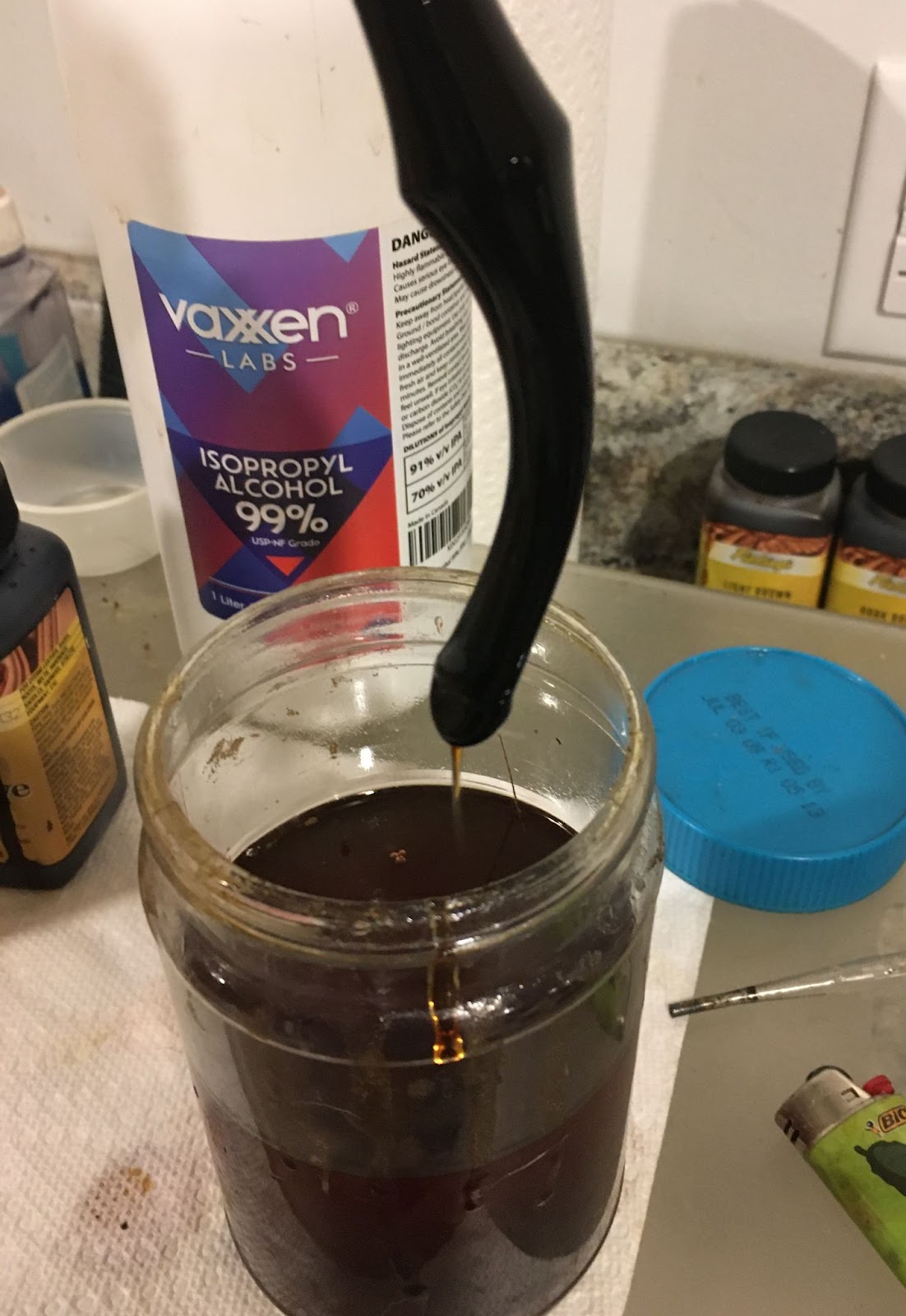

I allowed the dye to air dry for 20-30 minutes. I then mixed up some black Fiebing’s Leather Dye. I did this by diluting it – 2 parts black dye to one part 95% ethyl alcohol.

The stummel was then dyed black over the red. I was not quick enough to capture the flaming of the black dye. I allowed the black to air dry for 20-30 minutes.

Below are photos taken with the good camera of the dyed stummel.

The stummel was then taken to the buffer where I used a rouge buffing compound to lightly buff the high spots of the rustication.

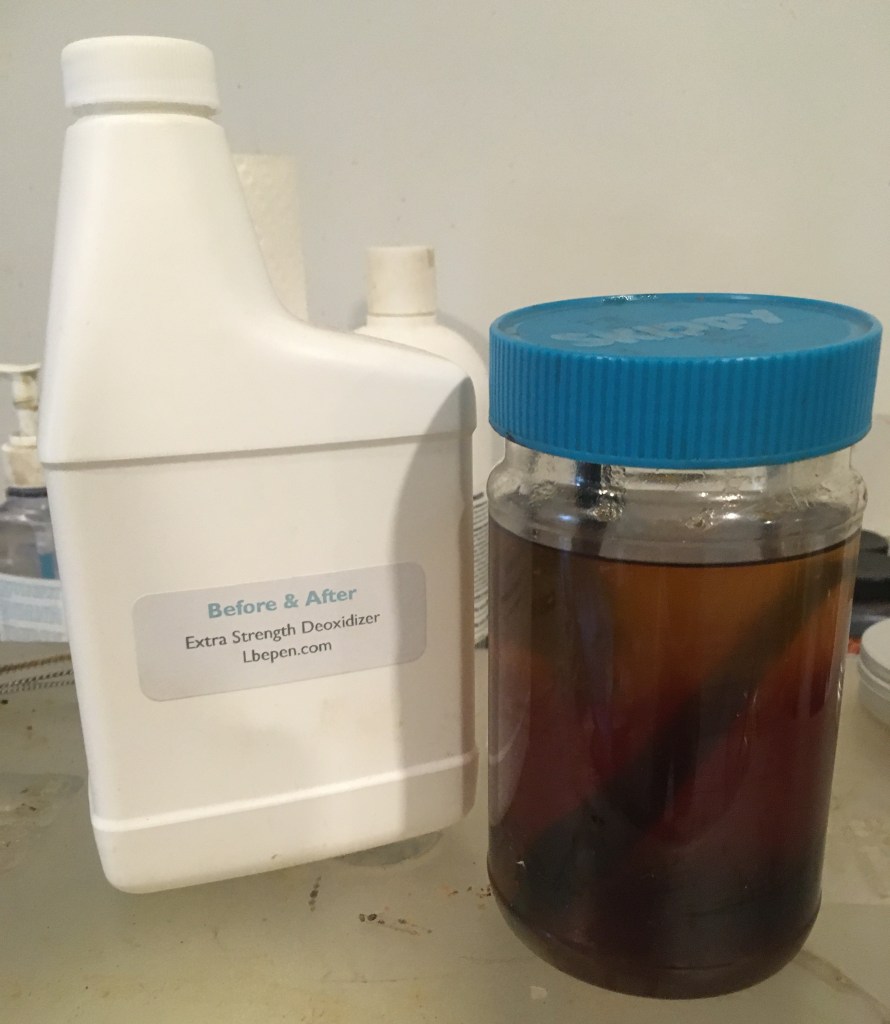

The stummel was then wiped by hand with a clean cotton terry cloth towel to remove any remaining compound and wiped with a coating of Before and After Restoration Balm.

It was time for the stem to exit the Oxy solution and return to the atmosphere. I wiped the stem vigorously with a make-up pad to dry the solution and buff off some of the loosened oxidation.

Next the stem was scrubbed with SoftScrub applied to make-up pads.

The outside of the stem was looking much better. It was now time to clean the airway of the stem. It was far better than the shank but still required several bristle pipe cleaners and alcohol.

I couldn’t wait any longer to see how the stummel would look. I used an inside out athletic sock to hand buff the excess Restoration Balm from the stummel. Eureka! I was pleased with the dye job.

Back to the stem. I thought I could get rid of the tooth chatter by painting the stem with a flame and sanding. I was wrong. There was one spot that I was not happy with so it got the old black cyanoacrylate (CA, super glue) treatment. The depression received a small drop of black CA. This was then spritzed with a CA drying accelerator. The cured drop was filed with a flat needle file and sanded with a 400 grit sanding sponge. This meant that I had to re-sand the top of the stem but the results were well worth it.

The stem was sanded with a series of sanding sponges from 600- 3500. Between each sponge I would dip the tip of my finger into mineral oil, rub the oil over the stem and wipe with a dry paper towel.

The stem was polished with Before and After Fine followed by the Extra Fine Polish. Then the pipe received several coats of carnauba wax on the buffer.

I think this GDB 1350 Apple turned out very nicely. Especially when looking back at the before photos. My goal of matching the red/black or burgundy stain was a success and the stem turned out better than I thought it would. The glossy black of the stem really works with the dark red dye on the briar. I do wonder how it would look with a bright brass band. I know it didn’t need a band but I think it would add something special to the pipe.

The dimensions of the GBD Sierra 1350 areas follows:

Length: 5.90 in./ 149.86 mm.

Weight: 1.13 oz./ 33.10 g.

Bowl Height: 1.81 in./ 45.97 mm.

Chamber Depth: 1.39 in./ 35.31 mm.

Chamber Diameter: 0.69 in./ 17.53 mm.

Outside Diameter: 1.26 in./ 32.00 mm.

I do hope that you have found something here useful to your own pipe care, maintenance or restorations. If you like this sort of thing, please click the like and subscribe buttons. Thank you for reading the ramblings of an old pipe lover.

Below are some photos of the finished GBD Sierra 1350 Apple.