Photographed and written by

John M. Young

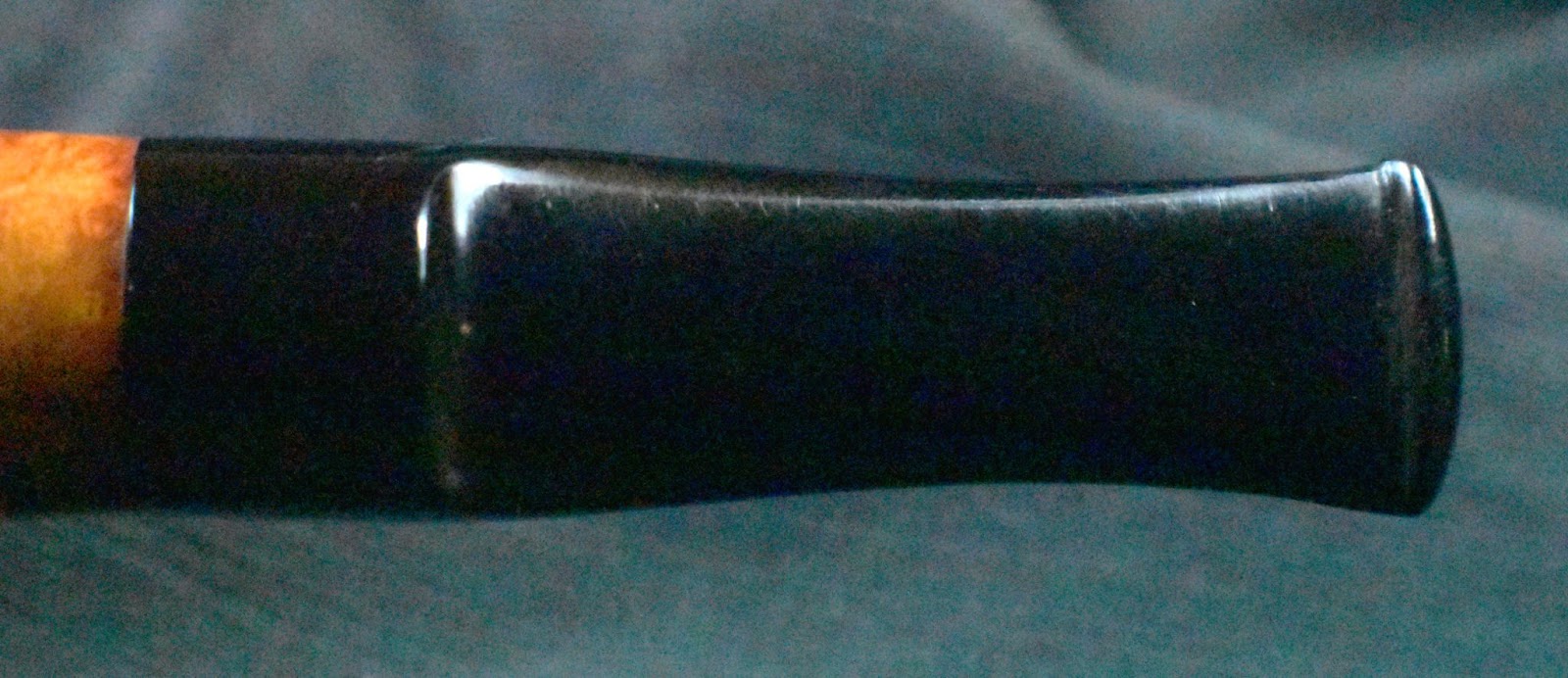

I’ve put a few bits in my mouth which were designed for denture wearers. Usually these are uncomfortable for me and my complete natural teeth. Heck, I’ve never even had a cavity. I know, hard to believe but true. I did try the bit of this Brigham and was surprised how good it actually felt. I am again getting ahead of myself. This restoration is of a 202 Brigham Two Dot Billiard pipe. It was another pipe that came from an estate lot. It was not the target specimen of the lot but more just a member of a group and subsequently got neglected in a box until I rediscovered it over the years later. I do not keep good records of when various pipes were purchased or from where. That may be a 2026 New Year’s resolution which I’ll likely forget to ever make much less abide by. Anyway, the pipe was stamped 202 (rather haphazardly on its bottom) to the right appears to be a double stamping of MADE IN CANADA, in a straight line over or under a more clear Brigham over CANADA. The photos show this more clearly than my description. Below are photos of the pipe prior to work being done:

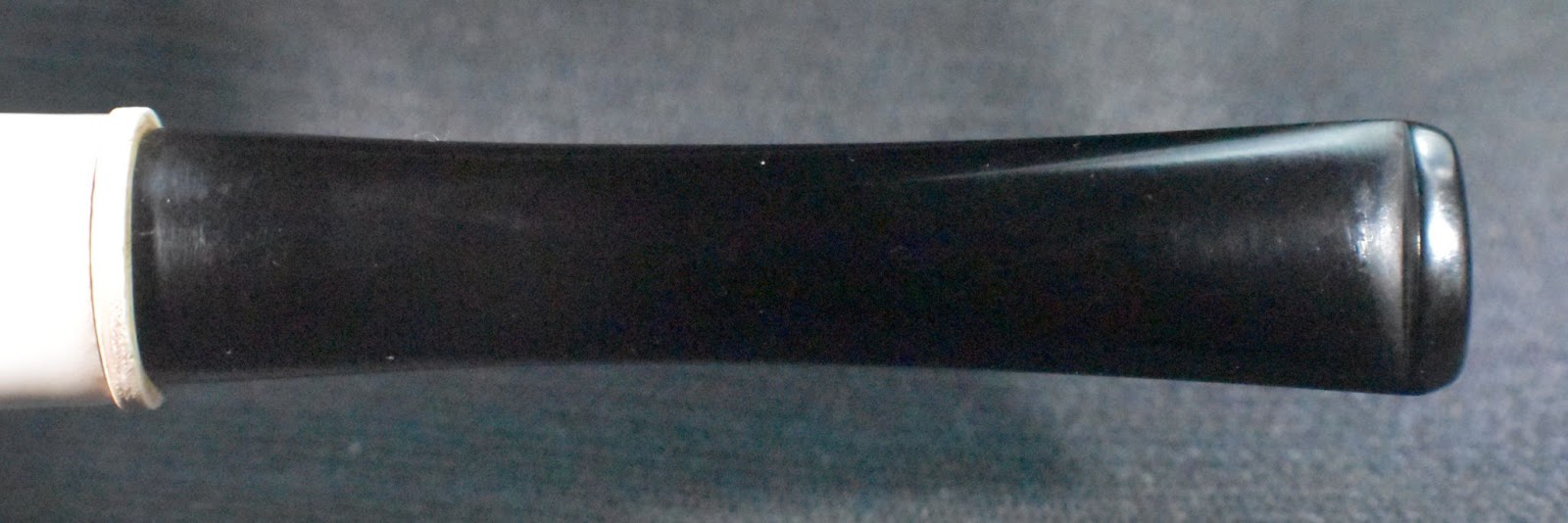

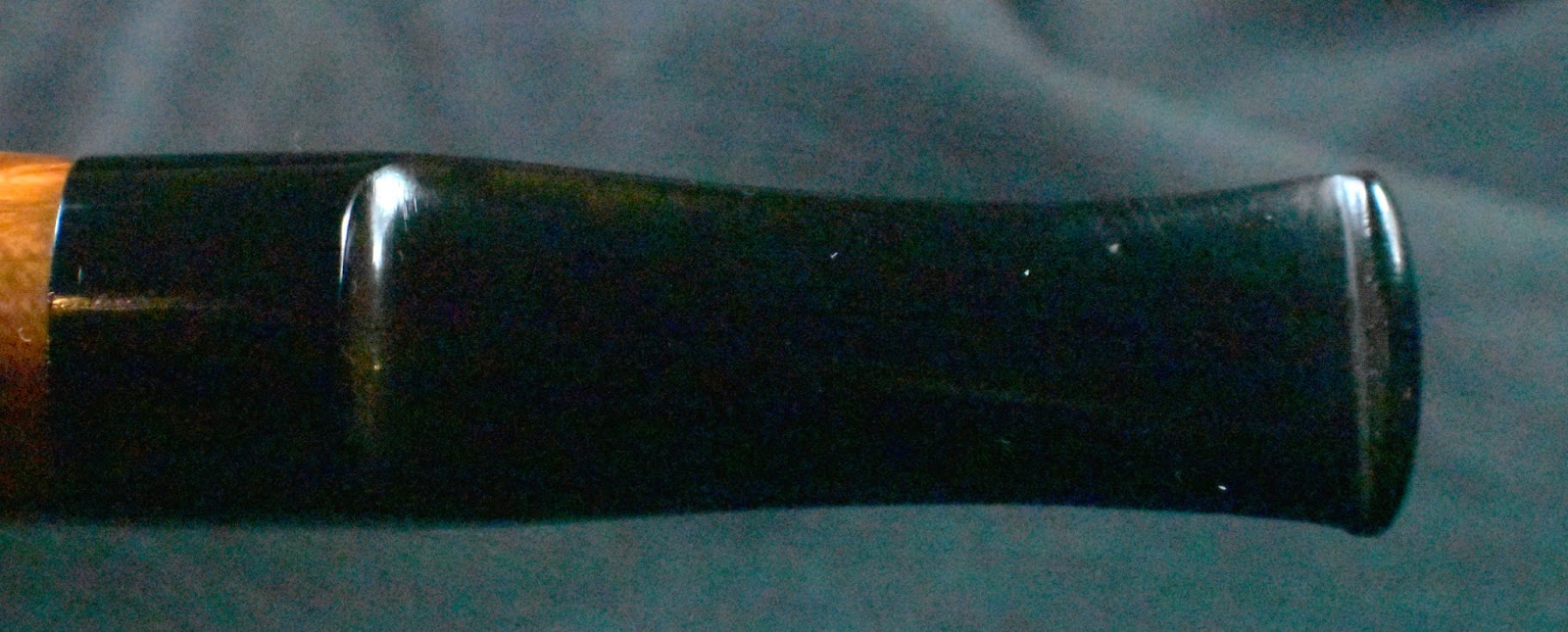

The pipe had obviously been a well loved and well smoked pipe. The tooth chatter and oxidation of the stem proved that. The amount of lava on the rim also was an indicator of the use this pipe had experienced. The tobacco chamber had been well maintained and looked fairly clear of a thick cake. This told me the previous owner liked a cleaned chamber and judging by the lack of any deep groves cut into the chamber they also had used appropriate tools to keep the chamber clean. The aluminum of the Brigham system was mostly free of oxidation externally and generally clean on the inside as well. This looked like it would by a straightforward restoration of a classic Brigham pipe.

Background

I admit that being my lazy self, I did a search on pipephil.eu for Brigham logos, knowing full well that this is a Brigham pipe.

(Brigham — Pipes : Logos & Markings) The pipephil page had entries for the 1-6 dot pipes as well as some additional specialty pipes. The two shapes from the “Two dot” entry appeared to have a “2” as their prefix.

I stopped being quite so lazy and got out my Brigham Pipe – A Century of Canadian Briar book to look for the 202 shape. Hmm, there was no 202 but there was an 02 Billiard offered since a 1939 Brigham brochure (Lemon, Charles. Brigham Pipe – A Century of Canadian Briar. Copywell, Woodbridge ON. Second Printing, October 2023. Page 17). My conclusion is that the Two dot Brigham is thus stamped 202. A three dot Brighan with an 02 Billiard shape would be stamped 302. Now, enough guessing. I decided to re-read the book.

The ultimate source of information on Brigham pipes is Charles Lemon, the author of Brigham Pipes – A Century of Canadian Briar. This wonderful book is available from Mr. Lemon on his website, Books, from smokingpipes.com (Brigham Pipes – A Century of Canadian Briar | Smokingpipes) if you need to increase the total of your purchase to get the ever popular free shipping, and other various sources. I am unsure about Canadian immigration rules but I think this book should be required reading for prospective immigrants to Canada, especially if they are pipe smokers.

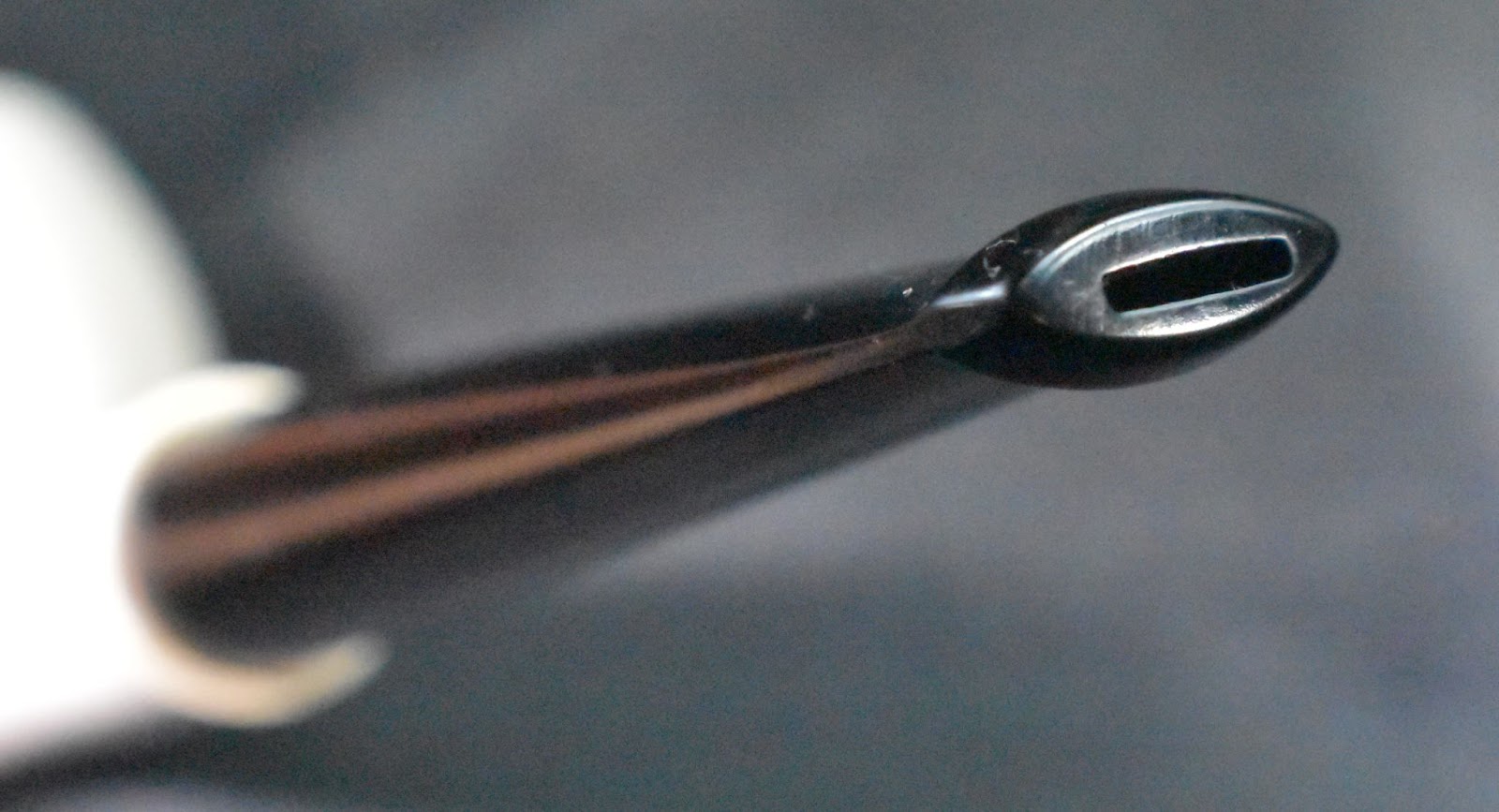

I could go on and quote Charles Lemon’s book extensively but that would require me to do so much typing and I have said it before and likely will say it again, I am a proud Generation-X slacker. Copy and Paste is so much easier. I will say that Lemon’s work is outstanding and it was a pleasure to read and in my case re-read, since old slacker minds apparently don’t hold as much information as they should. The re-reading was done to remind me how the shape numbering system works and to find references to the dental button. This elusive detail was not found and remembered from the first reading and failed to be found on the second round. I resorted to emailing Charles Lemon from the “contact” button on his website, www.DadsPipes.com. Mr. Lemon responded quickly to my request about information concerning the dental button of this pipe. I did include photographs of the pipe, stampings and button in my groveling email which also included a misspelling of the work “bok”. Yeah, it was supposed to say “book”, darn slackers…

Taking apparent pity on my groveling and lack of ability to spell, general ignorance about Brigham pipes, or maybe because he just a great guy, Charles Lemon replied with the following:

“Your pipe dates to the 1980s, and I suspect from the early 1980s. The 02 shape represents Brigham’s smallest Billiard, a shape that fell out of favour in later years as pipes became larger overall.

I don’t have any specific information about Brigham’s use of dental bits but I do know that Brigham offered a choice of stem shapes to clients when they ordered a pipe, dating to at least the 1960s. I suspect that your 202 is either one of the last of the optional stem offerings or a custom request. With the factory attached to the main retail outlet at the time, Brigham had an amount of flexibility to accommodate this sort of request if they chose to.

Hope that helps, It’s not a definitive answer, I know, but it is in keeping with how the company operated at the time. For what it’s worth, I have a small number of dental bits in the shop if you’re interested.” (Charles Lemon personal email)

Wow, is all I could say. Well, I did reply and say more than “wow”. There was also a thank you involved and probably some additional groveling.

That email response provided a pretty definitive date and explanation of the dental bit.

The Restoration

The restoration should have been a rather simple affair and as usual it started with a laundered denim piece on the workbench. Well, the stem got to sit on the denim at least.

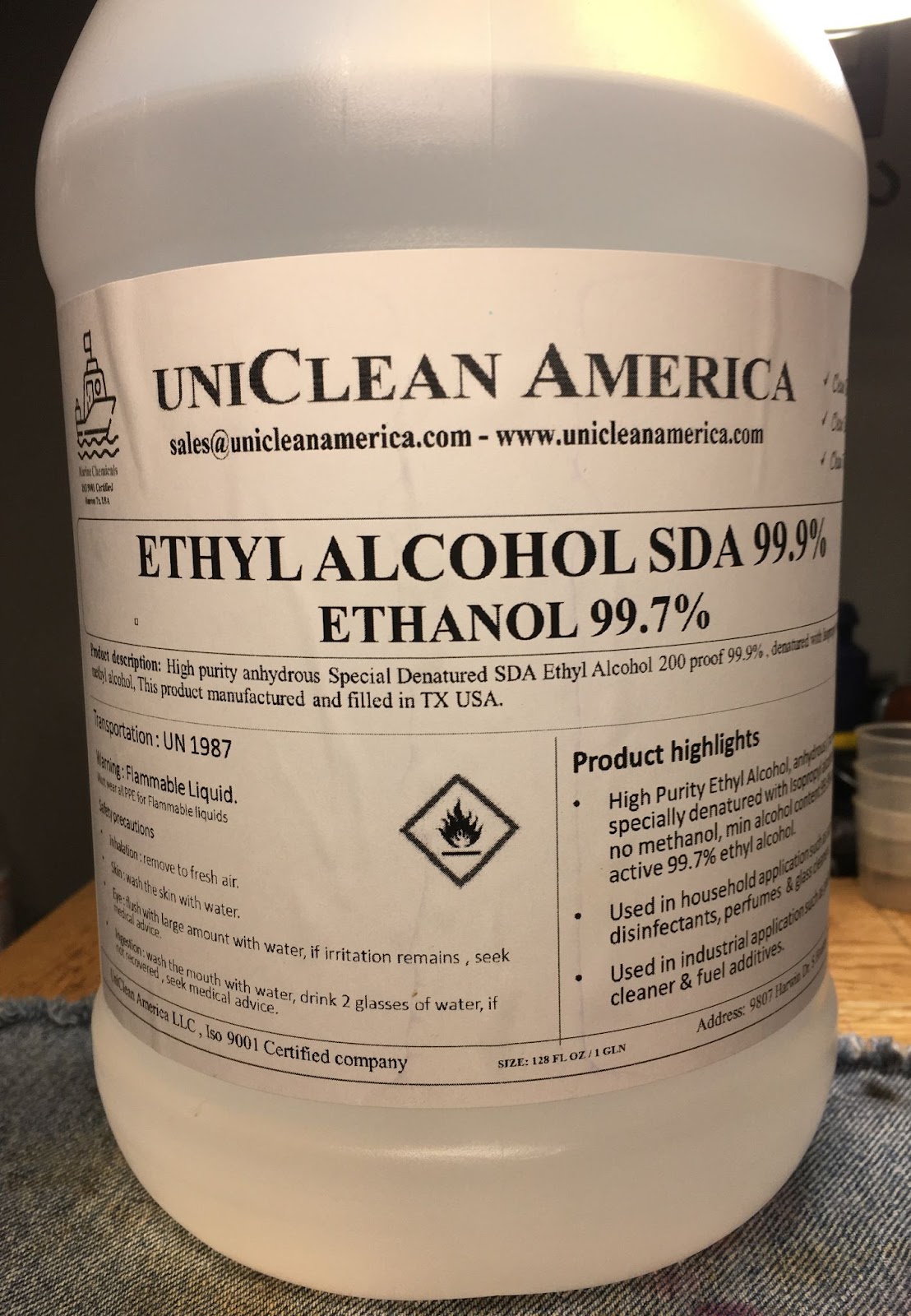

I started to clean the stem airway with a bristle pipe cleaner dipped in 99% ethyl alcohol. It was a tight fit at the slot then it became much easier after a tiny “tick” was heard. “Oh crap”, was probably the next sound heard. I had chipped the vulcanite at the slot with my rambunctious behavior. At least that is what my mom always said after I broke something, “Stop being rambunctious!” Hmm, why didn’t she yell that before I broke something? The chip was tiny and fit back together very nicely so I set it aside where it would be safe.

I continued on filing the tooth chatter and smoothing the area above the button. Two small files, one flat the other a tapered ½ round. The rounded file fit the rounding of the underside of the dental button nicely. These areas were also sanded with a 320 sanding sponge as I went.

I then proceeded to clean the stem, with less rambunctiocity. Wow, spell check didn’t say that wasn’t a word.

The stem was allowed to soak in Before and After Extra Strength Deoxidizer. It went in on a Sunday late afternoon. I had to attend a funeral for a cousin in northeast Iowa so it sat in the deoxidizer for about 30 hours.

Upon returning to the wilds of southeast Nebraska, I took up the restoration the next night. If you look carefully at the below photo you can see the chip from the stem propping the pipe up. Apparently that was the safe stop to keep the chip. I cleaned out the shank with a shank brush, cotton swabs and bristle pipe cleaners all dipped in 99% ethyl alcohol. If you are wondering about the purple on the cotton swabs it is probably potassium permanganate (KMnO4). Here is a quote from a chemical supplier who still sells KMnO4 “Potassium Permanganate is a dark purple solid. Dissolving 1 ounce in a pint of water is used to stain woods a pleasant brown. The Potassium Permanganate decomposes on contact with the wood and leaves a brown residue that stains the wood. If the color is too dark it can be lightened by washing the wood with a strong solution of hypo. The brown color imparted to fairly woods will gradually fade when exposed to direct sunlight. Mix only enough solution to do the job at hand as the solution on long standing will lose its effectiveness. Use it with caution as it is a strong oxidizer.” (POTASSIUM PERMANGANATE | WoodFinishing Enterprises)

Next came the assembling of the ream team.

The PipNet with its #1 and #2 blades did most of the work.

The Smokingpipes Low Country reamer and the General triangular scraper were used to touch-up the tobacco chamber.

The reamed chamber looked very good and showed no signs of any heat damage.

I sanded the interior of the chamber with 220 sandpaper wrapped around a wood dowel followed by 320 sandpaper wrapped around a Sharpie marker.

The bare briar indeed was free from any damage.

The rim would hopefully be also free of damage under the layer of smoking residue, aka lava.

The lava was moistened with saliva and gently scraped with a sharp pocket knife.

The stummel was then taken to the sink for a scrub with undiluted Murphy Oil Soap and a nylon brush. The soap was rinsed with warm water and the stummel dried with a cotton hand towel.

Back at the workbench, I wiped the stummel with an alcohol wetted cotton ball. Some color came off the pipe. I did not want to change the look of this pipe by removing and rebuilding the finish.

I gave the stummel a coating of Before and After Restoration Balm and set it aside to work its magic overnight. Hey look, that little ship is still there. Safe and sound.

After the funeral, still the next day though, I returned to working on the pipe. I saw a small black fleck on my denim and threw it into the trash. Stupid little black flecks. I then wiped the remaining Before and After Restoration Balm off of the stummel using an inside out athletic sock.

I retrieved the stem from the Before and After Extra Strength Deoxidizer. I’m just going to call it deox from here on. Nothing personal to Mark Hoover, but that is just too much to type. I placed the still wet with deox solution on my favorite coarse shop rag. The deox on the aluminum had foamed up, presumably a reaction of oxidized aluminum to the deox solution.

I vigorously rubbed the vulcanite with the coarse gag. This absorbed excess deox and abraded away some of the oxidized rubber. Actually a lot of the oxidized rubber.

Back at the workbench, I cleaned the interior of the stem with several thick pipe cleaners then coated the stem inside and out, with Before and After Hard Rubber Balm (HRB, henceforth). This is another great product from Mark Hoover. I like it best as a preservative on a finished stem to combat oxidation but it works well on a stem fresh out of deox too.

The deox had left a mark of the aluminum of the Brigham system. The cleaner shiny aluminum clashed with the more dull original aluminum.

I hand buffed this using Before and After Fine Polish on a paper towel. Tada, much better.

I looked over the tooth chatter and cleaned the HRB from the bite zone with alcohol on a cotton swab. I was prepping the area for a small drop of black cyanoacrylate (CA, super glue) to fill the depression.

It was about here that I realized the little black fleck that I threw away was the chip from the button. “Oh crap!”, may have been spoken. The poor little chip had evaded trouble by staying in its safe place for a couple days before some rambunctious oaf displaced it.

Hmm, how hard could it be to find a tiny black fleck in the trash bin of… a guy who dumps lots of black powdery debris… in the trash bin. Oh crap.

I set out a piece of scrap packing paper and went through the trash, shaking the bigger pieces to dislodge a small black fleck. Eventually I dumped the reaming debris onto the paper, got down on my less than flat belly and started sifting through the black powder searching for a fleck.

Hah! Victory. I actually found the little bugger. By the way, if you think that it’s easy being this dumb, you would be mistaken. It takes years of training and classes in rambuctiocty from the local community college.

And it still fits.

The wound was cleaned with alcohol in preparation of the regluing. I thought about drilling and reinforcing the chip with a 2 mm brass pin but the rough surface of the break and the contours of the fit seemed like they would provide good support on all three sides.

I used a plastic lid cut-out inserted into the slot to keep the CA from being rambunctious. Yeah, I’m going to see how many times I can use that word.

The glue of choice was This rubberized CA from Bob Smith Industries. It was getting a bit old and wasn’t as thin as it used to be but it coated the contact surfaces well. A drop of the CA was placed on the disposable pipette bulb then applied to the stem with a fly tying bodkin.

Once that CA had set, I applied a thinner black CA to fill the seams.

Once the thinner CA set, I applied a bead of the first black CA to the edge of the button to address the rounding of that edge by previous tooth wear and tear.

Once all the CA had cured, I again filed the CA with the two files used earlier then started the sanding with a series of sanding sponges. Between each sponge I rubbed the stem with mineral oil then wiped it with a paper towel.

I was still not happy with the seam of the glueing so I sanded that additionally with 400 grit sandpaper wrapped around the handle of an Exacto knife. I kept my rambunctious nature in check and did not skewer myself with the blade. Yeah, it would have been smart to remove the blade but, it is me we’re talking about here… I then polished the stem with new micro-mesh pads in grits of 4000-12000.

To avoid having another pipe cleaner chipped button incident, I used a cut-off bit in the Dremel rotary tool which was a fraction of a mm thicker than the original slot. This widened the slot enough to pass a pipe cleaner, even bristled, more easily. The slot was polished with a thin folded piece of 400 grit sandpaper.

The pipe was then taken to the buffer for several coats of carnauba wax. This was then hand buffed with a microfiber polishing cloth.

I do hope that you had fun reading about the trials and tribulations of not being the sharpest tack in the pack. I will continue making mistakes and documenting them in hopes that you can learn from them in a less painful fashion than I. This Brigham was actually a fun little pipe to work on. The fact that it was a non-typical version with a dental stem made it more interesting to me. Thank you again Charles Lemon for the insights into Brigham pipes. The pipe itself is a lovely example of a two dot Brigham. The rustication provides an attractive and comfortable bit of briar and the stem though lacking the robustitude to weather a rambunctious restorer still turned out very nicely. The dimensions of this Brigham 202 are:

Length: 6.49 in./ 164.87 mm.

Weight: 1.33 oz./ 37.06 g.

Bowl Height: 1.72 in./ 43.69 mm.

Chamber Depth: 1.41 in./ 35.81 mm.

Chamber Diameter: 0.72 in./ 18.29 mm.

Outside Diameter: 1.30 in./ 33.02 mm.

I do hope that you have found something here useful to your own pipe care, maintenance or restorations. If you like this sort of thing, please click the like and subscribe buttons. Thank you for reading the ramblings of an old pipe lover.

Below are some photos of the finished Brigham 202 with a dental stem.