Written and photographed by

John M. Young

I know what you are thinking, “Good Lord, man. Another Marxman? Why don’t you expand your repertoire?” Hah, I say, and stop questioning my motives in French. Just because the French are almost solely responsible for bringing briar to our beloved past-time, that’s no reason to start throwing French terms around. Besides, it is probably becoming known that I really like Marxman pipes.

My recent fascination with the post-World War Two (WWII, to properly use an acronym). Led me to further appreciation of the Marketing genius of Robert Marx, the founder of Marxman Pipes Inc. Allow me to illustrate:

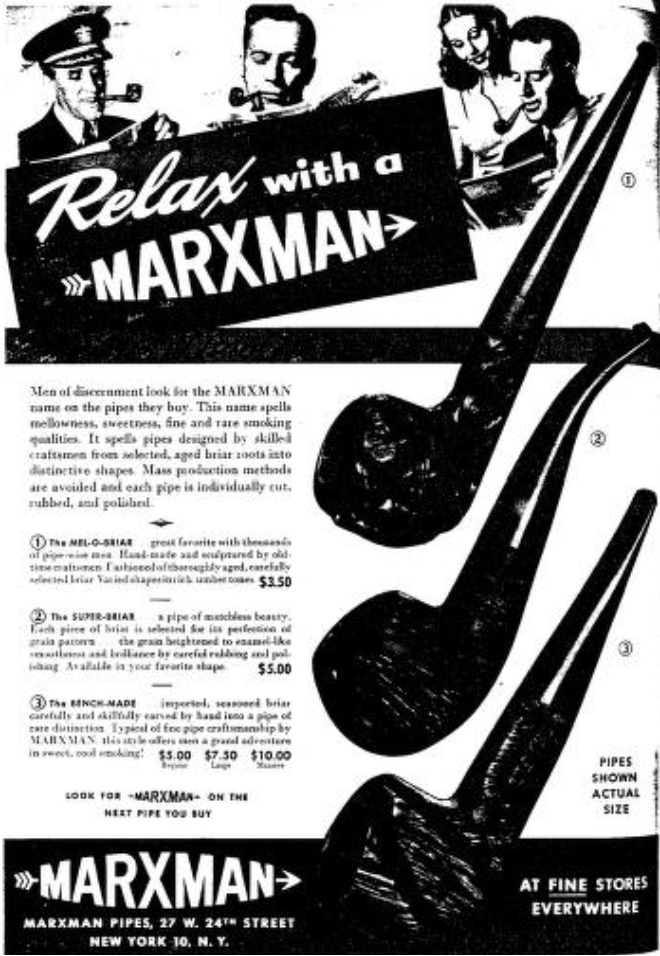

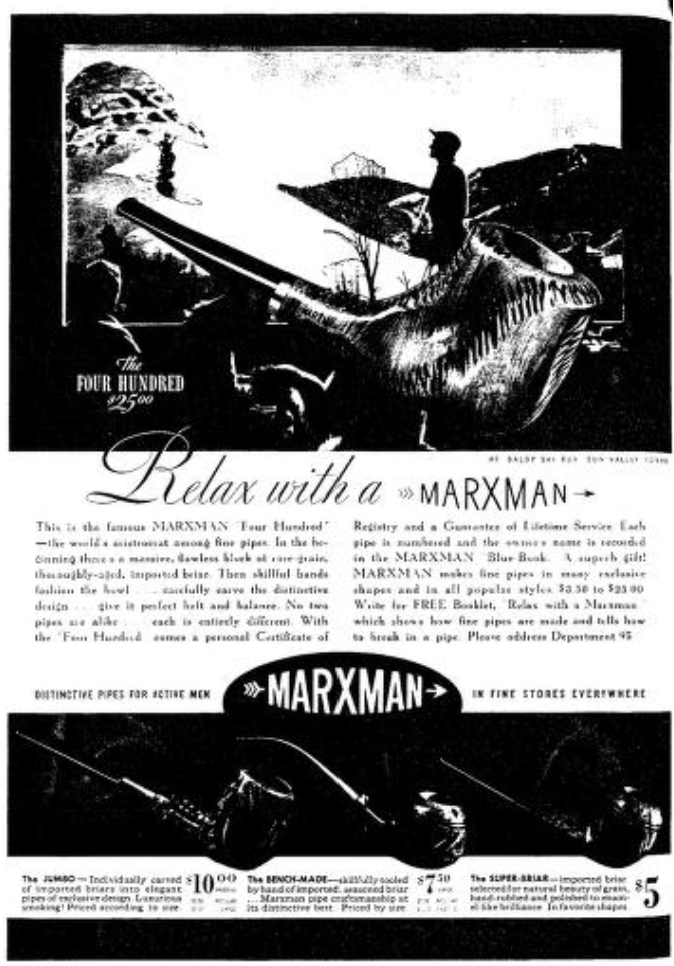

(Pipe Lovers Magazine 1946 all numbers : Free Download, Borrow, and Streaming : Internet Archive)

Those are the back covers of Pipe Lovers Magazine for each month of 1946. That represents a substantial investment in building and maintaining one’s brand name.

Here is a quick review of Marxman pipes from pipedia.org:

“Marxman (Marxman Pipe Company) was created by Robert (Bob) L. Marx in 1934, when he was 29, and after he had worked for the William Demuth Company. His pipes were not outstanding because of the quality of their wood (probably Algerian), but Bob started making unique sculpted pieces, which brought the brand fame in the World of Hollywood cinema. Actors like Zachery Scott, Dennis Morgan, Jack Carson, Alan Hale, Joel McRae, and Ronald Reagan were some of the faces that appeared on the bowls.

Bob knew how to innovate and took full advantage of marketing and press advertising in order to sell the brand–one of his slogans being “Relax with a Marxman”.

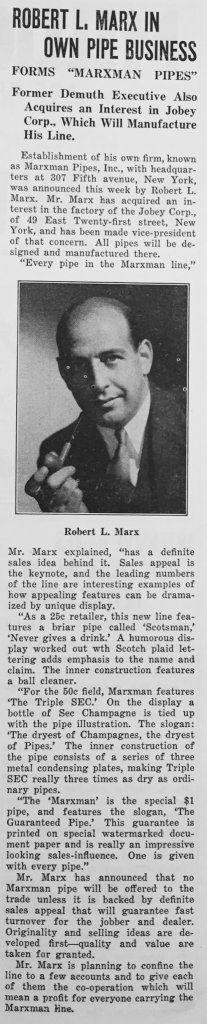

In a recent forum post on Pipesmagazine.com, contributor jguss posted the following from the February 2, 1935 issue of the United States Tobacco Journal:

A remarkable article showing the business acumen as well as a photo of the man himself. Thank you, jguss.

This is one of my favorite quotes about Rober Marx:

“Ted also said: Several years before UST bought Mastercraft, M/C had aquired Marxman Pipes. A wonderful kind man, Bob Marx was still working as a salesman in NYC, and I was fortunate to make a few sales calls with him. You all remember Charles Atlas? Bob Marx was about 76 and had just been awarded the (I think) Atlas Award for being the finest speciman of manhood over 70 years old in NYC, or maybe the state.

M/C had some inventory of Marxman stuff, but not a lot. I know very little about Marxman. Did they make, import, or both?” (Mastercraft – Pipedia)

The “Ted”, who is being quoted above, was the nickname of Tom Douglas. Here is an announcement of Mr. Douglas’ passing from Pipesmagazine forum November 26, 2018:

“Tom Douglas passed away at 71 years of age, this past Saturday, in Florida. It seems he had an infection in his stomach, but I don’t know much more than that, regarding what actually contributed to his death. He did have a history of heart and other health complications. I just spoke very briefly with his wife Joyce; you can imagine how she’s doing.

The impact Tom had on the pipe community is huge…beginning with an immense library of pipe knowledge through the pages of the Dr. Grabow Collectors Forum….his 25 years of service at the Grabow / Sparta pipe factory (where he retired in 1991)….his executive leadership over Mastercraft distribution for many years…”

So, at 76 years old Robert Marx was still involved in the business that he must have loved. This would have been around 1980.

Onto the pipe at hand. This Marxman Dublin was in the same estate lot as the Winthrop (previous blog) and the Manhattan (future blog). The Manhattan (c. 1922) is awaiting parts needed for completion. The final pipe of the 4 is a promotional pipe stamped with “Tropical Paints” over “Cleveland”. That one will be a fun research project, I am sure.

The Marxman Dublin had seen a great deal of use, some of it well beyond use and into the abuse category. Here are photos of the poor darling upon arrival.

Yeah, she needed a lot of attention. This one may require me to find a new historical drama series to have on in the background while I work. Okay, probably not a whole series but, a solid 5 episodes.

The only thing that is in surprisingly good shape is the stem. The previous owner may not have ever heard of a pipe cleaner but he wasn’t a biter. Okay, that was kind of sexist – they were not a biter.

I started by disassembling the pipe. You probably noticed that the stem was not fully inserted in the photos. I removed it when it first arrived. It was very tight and I didn’t want to force it back into place for the photos. I also removed the gold band, which surprisingly did not conceal a cracked shank. Like Forrest Gump said, “that’s good! One less thing.”

I then began to ream the tobacco chamber. The cake was very hard and did not want to relinquish its hold on the briar. Hmm, I’ve had Marxman pipes

with Algerian briar before that literally slough off their cake with little effort. It took all the reaming tools to get this task finished. The Scottie reaming tool, the Pipnet, the Smokingpipes Low Country knife, the General triangular scraper and of course the 220 sandpaper wrapped around a wood dowel. The inspection of the interior of the tobacco chamber revealed that not only was the previous owner cleaning averse but also a puffing machine. The chamber showed signs of heat damage and charring on three sides. The repair of the damaged bowl took some thought while working on other issues.

After the Tobacco chamber I started in on the shank airway. This cleaning nearly made me rethink my life choices and hobbies. I could give you the short version and say something like “81 cotton swabs and a highball glass full of alcohol later, the shank was clean.” I know you would rather hear the long painful real experience. First off, let me say that this was perhaps the most filthy shank I have ever cleaned out. Now it could be that I had wiped worse shanks from my memory but I don’t think so. This shank was a bear to clean out. I will let the photos speak for themselves. The process was as follows:

- Pour 3 ml of 99% isopropyl alcohol into the bowl.

- Plug the mortise with a finger and tilt stummel to wet the airway with alcohol

- Use a .22 caliber brass bore brush to scrub the interior of the shank.

- Use 3-4 cotton swabs to scrub the airway absorbing the dissolved tars and remaining alcohol from the shank.

- Repeat until clean.

After a few (AKA bunch) of repetitions. I tried rolling a 5cmx5cm piece of paper towel around a round needle file. This was dipped in alcohol and used to scrub the airway. When it came out I’d unroll it and reverse it and reroll the paper towel to scrub with a clean side. Thus the paper towel pieces in the photos. I eventually got tired of my continual failures and decided to pack the tobacco chamber and shank with cotton and let the interior soak in alcohol/cotton overnight.

The next morning the cotton was stained with the tars that had dissolved from the stummel and got absorbed into the cotton as the alcohol evaporated. I removed the cotton and started the above scrubbing procedure (steps 1-5) repeatedly.

Above was the first cotton swab used after the overnight alcohol/cotton treatment. Yep, it is still nasty and tar filled.

A bunch of swabs later I was finally getting lighter colored swabs out of the shank. Long story-short = 81 cotton swabs were defiled with this one shank. I was victorious.

The stem was next on the hit list. After just finishing the shank from hell, and looking at the button, this is going to be fun. I used the dental pick in an

attempt at opening up the airway at the button. That tar and smoking residue was nearly as hard as the stem. Eventually, I was able to get a pipe cleaner all the way through the stem. I thought this would be a good candidate for the churchwarden-pipe-cleaner-in -the-vise routine. That is where you clamp one end of a bristle pipe cleaner into a vise, thread the pipe cleaner through the airway, using a pipette soak the pipe cleaner with alcohol and move the stem up and down the length of the pipe cleaner.

Usually a dirty stem will use two churchwarden pipe cleaners. This one took 6 plus the 6 to get the stem to accept a pipe cleaner and it was still dirty. I was getting frustrated. I returned to the

workbench and dipped a bristle pipe cleaner in acetone. It came back even more soiled that the pipe cleaners dipped in alcohol. I repeated this 3 more times. Every one came out as filthy as the one before it. I took the stem to the sink and ran hot water through the stem, thinking that maybe that would loosen the yuck better. I then used a bore brush with dawn dish soap. After the Dawn, I repeated with Castile soap all with hot water. I then tried a pipe cleaner dipped in alcohol. Surprise, still coming out brown. I continued with running the hot water through the stem then scrubbing with an alcohol dipped pipe cleaner for another 6 days. Ok, that may be an exaggeration. It might have been 15 minutes. Eventually the pipe cleaner did emerge without any yuck.

Cleaning done, time to move on to the sanding. I used the 400 sanding sponge followed by the 1000 sanding sponge. This allowed me to get a better look at the areas that needed to be filled. I saw a couple of spots. I placed a small drop of clear thin cyanoacrylate (CA, super glue) on the spot and immediately sanded with the briar dust filled sanding sponge over the top of the CA. This enables the briar dust from the sponge and sanding to stick to the CA and fill the pit. This technique is good for small shallow pits and is not suitable for larger deeper fills.

Next was to top the rim. I used a piece of 220 sandpaper laid flat on a countertop as the topping surface. The stummel is rotated in a circular motion while trying to keep even pressure. Every three rotations I spin the stummel 90 degrees in an attempt to evenly remove material from the rim. Once the desired amount of material is removed I sand the rim with a piece of 400 sandpaper laid flat on the countertop.

This rim was beaten up pretty badly. Rather than removing an eighth of an inch of stummel I topped the rim to remove most of the damage then beveled the inside and outside of the rim. I used a wooden ball wrapped in 220 sand paper for the inside bevel and a 220 sandpaper lined funnel for the outside bevel.

With the fills filled and the rim topped, I was able to get a good look at the grain of this briar. It was rather unimpressive. Now, I know that Algerian briar is not known for outstanding grain, great smoking – yes, great grain, not so much. This pipe was what I would call, “less than”. I thought maybe a bit of contrast stain would bring the little grain present to a better light.

I prepped the dyeing/staining area. Side note: I know that I am using a dye

not a stain. I just can’t get used to the term dyeing when working with wood. Staining wood is ground into my being from Wood Shop in middle school. The required gear is a paper towel covered surface, Fiebing’s Black Leather Dye, a folded pipe cleaner, a disposable lighter and the official duct tape wrapped fishing bobber. Yeah, I know, most people use a wine bottle cork, those are in short supply due to my tea-totaling life.

I purposely spilled dye on the paper towels to stress the importance of this step. Yeah, that ‘s what happened, purposely. It is a good idea to wear nitrile gloves when working with leather dye – good thing I forget that. After the dye had dried I wiped the stummel with a make-up pad wetted with alcohol. I then sanded the stummel with the 400 sanding sponge to remove the outer layer of black stained briar. I’d like to say the results were phenomenal. I’d be a liar. The results were more like, nominal. Oh well maybe, it will look good after the restoration balm?

Taping the gold band and stamps then working through the sanding sponges were the next steps. The sanding sponges 1000-3500 were used on the stummel and stem. The stummel was wiped

with an alcohol wetted make-up pad between sponges while the stem received a light coat of Obsidian oil from my fingers and was wiped with a paper towel. Looking down at the workbench I saw that gold band wrapped in blue tape. Why the heck did I do that? I never had it on while I was sanding.

It was getting to the time when I had to decide what to do about the damage to the inside of the bowl. Options:

- Redrill the tobacco chamber.

- Use a pipe mud made from cigar ash and water to fill the cracks.

- Use JB Weld epoxy to fill the cracks

Hmm, number one sounded a bit extreme and would require me to buy some significant equipment. While not averse to the idea of buying some large tools I am economically unwilling. Number two sounded reasonable. This pipe will never be sold due to the extensive repairs and will remain with me or be gifted to a friend who understands what they are receiving. I am out of cigar ash and really don’t enjoy smoking cigars. That left option three. I have JB Weld and I’d used it several times with great success. It definitely won’t fall out like the pipe mud might.

Yeah, that is almost as scary at looking at MRI images of my brain with my neurologist. First I worked a 20 gauge brass bore brush around to get rid of any loose charred material.

Then I mixed the epoxy as stated by product instructions with a little bit of carbon powder. I remembered to wear nitrile gloves and place a pipe cleaner in the airway. I bet you didn’t think I’d remember either of those. Using the epoxy on a nitrile covered finger, I smeared it evenly over the inside of the bowl. I planned on sanding the interior leaving the epoxy only in the depressions once it had cured in 24 hours. JB Weld can be wiped from any surface where I didn’t want it with a make-up pad dipped in acetone. I did this around the inside edge of the rim.

This restoration had already taken a full day more than I had anticipated. Not wanting to waste any more time waiting for the epoxy to cure, I taped over the tobacco chamber to keep dust and debris off of the curing epoxy. Micro-meshing came next, here I used the 4000-12000 micromesh pads in sequence with the same wiping between pads as I did with the sanding sponges.

Getting nearly finished. Well, after waiting for the 24 hours of epoxy curing, that is. I still needed to reattach the gold band. The stamp on the band says “14K RGP.” This would indicate a 14 karat rolled gold plate. I used the fly tying bodkin to lay a bead of brown CA around the outer edge of the shank. I then carefully slid the band into place. I set it aside to dry. During the drying I took the stem to the buffer. The stem had been micro-meshed when I was doing the stummel but, I needed something to do while the CA set with the band. I buffed the stem with a red buffing compound and wiped it clean with a cotton cloth.

After a few minutes I returned to the stummel and reattached the stem. It was slightly loose. It probably would have tightened up by smoking a bowl of tobacco but the epoxy was not cured and not sanded. I decided to give it a quicker tightening with a bit of Bee’s wax. I placed 3 kernels of wax on a spoon and warmed it over a burner on the stove. Once melted I rolled the tenon in the melted wax. This was allowed to cool then I pushed the tenon ½ into the mortise. That pushed the extra wax back toward the stem. I used an Exacto knife to cut away the extra wax and pushed it ¾ into the mortise. Again I cut away the excess wax. Then slid the stem all the way into the mortise. Perfect tightness.

I then took the pipe to the buffer for a couple of coats of carnauba wax. Yeah, I know, I didn’t do the Before and After Restoration Balm. In all honesty, I was getting a bit tired of working on this Marxman Dublin. The stummel took to the wax very nicely and it looked pretty good. I will let the epoxy cure for the required time before I try sanding the interior of the tobacco chamber. I may need to apply a second coat of epoxy to fill some of the deeper grooves. I’ll know more tomorrow. For now, I am calling this Marxman finished. Three days and still not finished is a long time for me to work on a single pipe. Even my love of Marxman pipes has a limit.

Overall I am glad to be done… Um, I mean I am happy with the way this pipe turned out. For a pipe that was; as filthy as this one was, has rather unattractive grain and has charring in the bowl it turned out well. I will give it a chance and smoke it in a couple of days. It may be one of those magical pipes that smokes so well it will replace a favorite. “May” is not just the month after April, it is also a very big qualifier here. This pipe obviously was someone’s favorite pipe for a long time. That may be an indication of it’s potential. I do hope that you found something here useful for restorations of your own or at least were entertained. If you like this kind of thing, please click like and subscribe. Thank you very much for reading the ramblings of an old pipe lover.

Below are some photos of the finished (nearly) Marxman Dublin with a gold band.