Photographed and written by

John M. Young

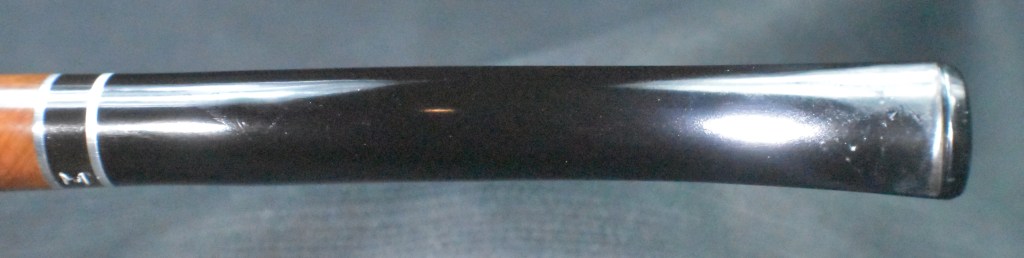

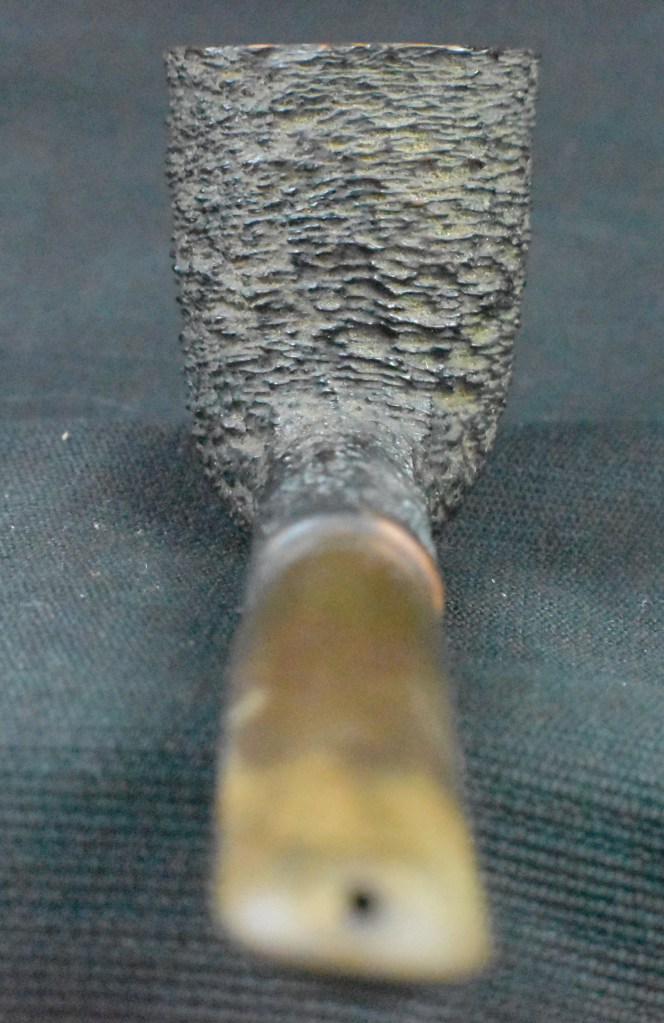

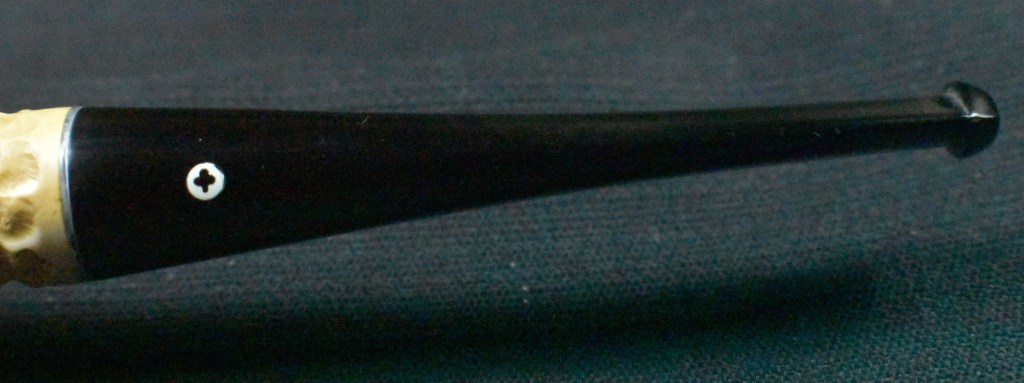

This is another “tag-along” pipe, one of those unintended-though-not-unwanted but part of the estate lot. This one is a Medico Medalist in the author shape. I have to say that Medico makes a very attractive author. The pipe arrived here last May and has been patiently waiting for restoration in the queue. The pipe is stamped MEDICO over Medalist (in script) over IMPORTED BRIAR on the left shank. No shape number nor country of manufacture (COM). There was also a stamped and painted M in between two aluminum rings on the stem. Below are some photos I took prior to beginning work.

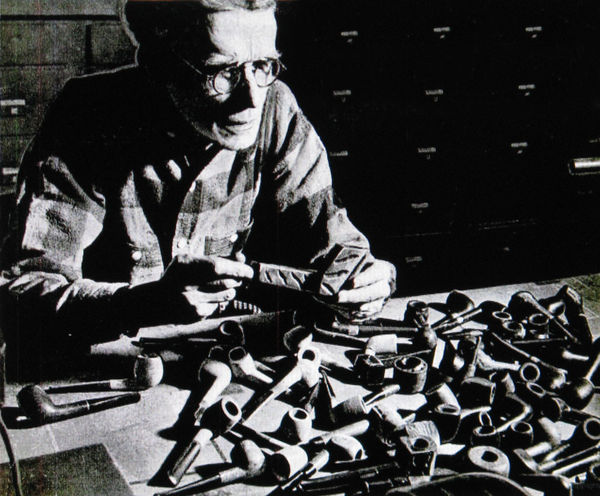

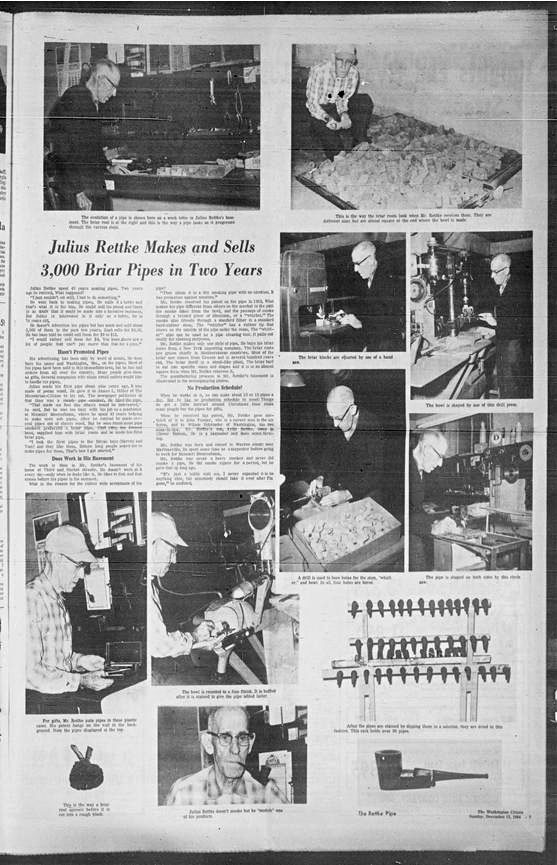

Background

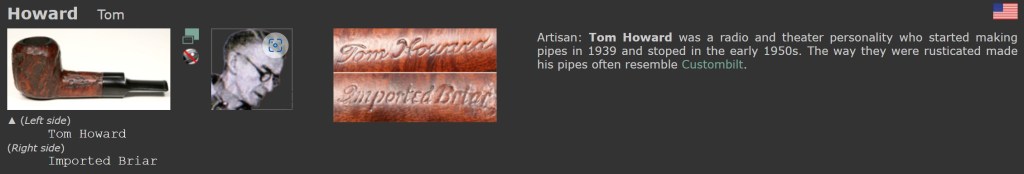

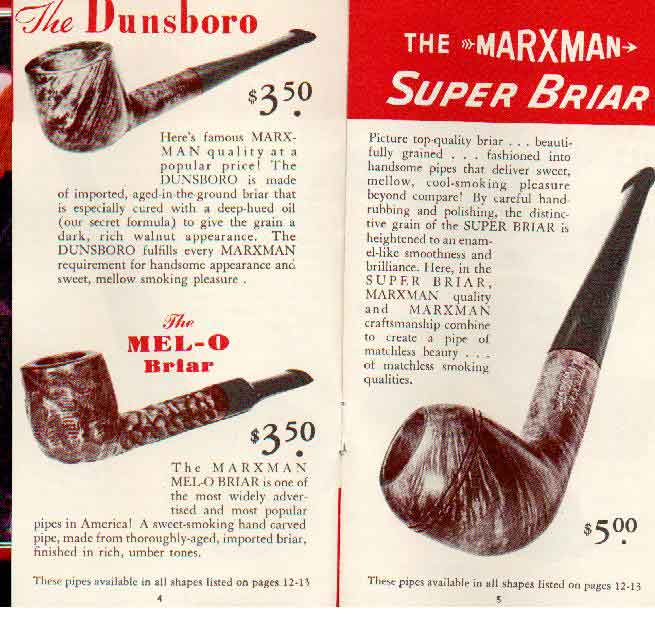

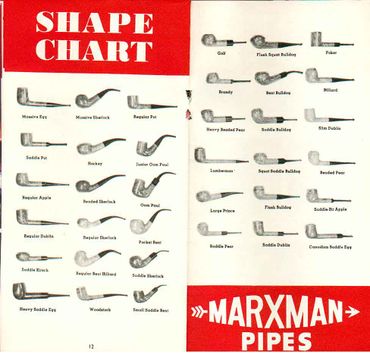

Medico pipes have a long history all the way back to SM Frank around 1900. According to TobaccoPipes.com,

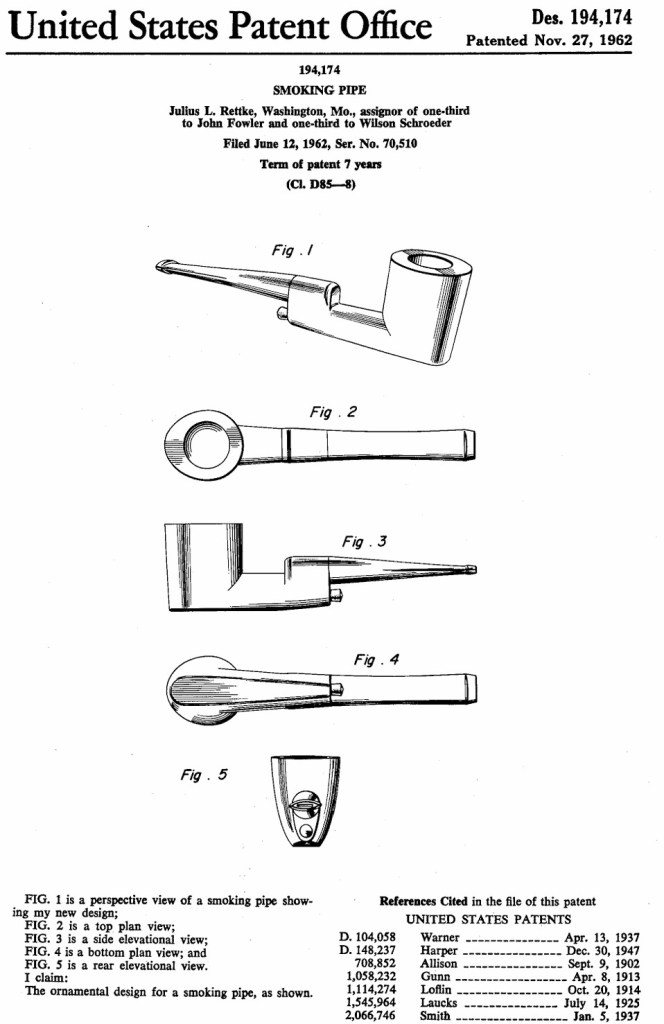

“When you trace the Medico tobacco pipes history, you have to trace it back to the origins of the company that created it. The company that originated the Medico brand is the S.M Frank & Co. This company dates back to the year 1900. In that year, a man named Sam Frank began selling pipes and related tobacco products. Eventually, the company began making its own line of pipes. With the help of an experienced pipe manufacturer, Ferdinand Feuerbach, the company produced the popular Royal DeMuth and Hesson Guard Milano tobacco pipes. The company continued to grow well into the early part of the 1930s.

So, where did Medico pipes come into the picture?

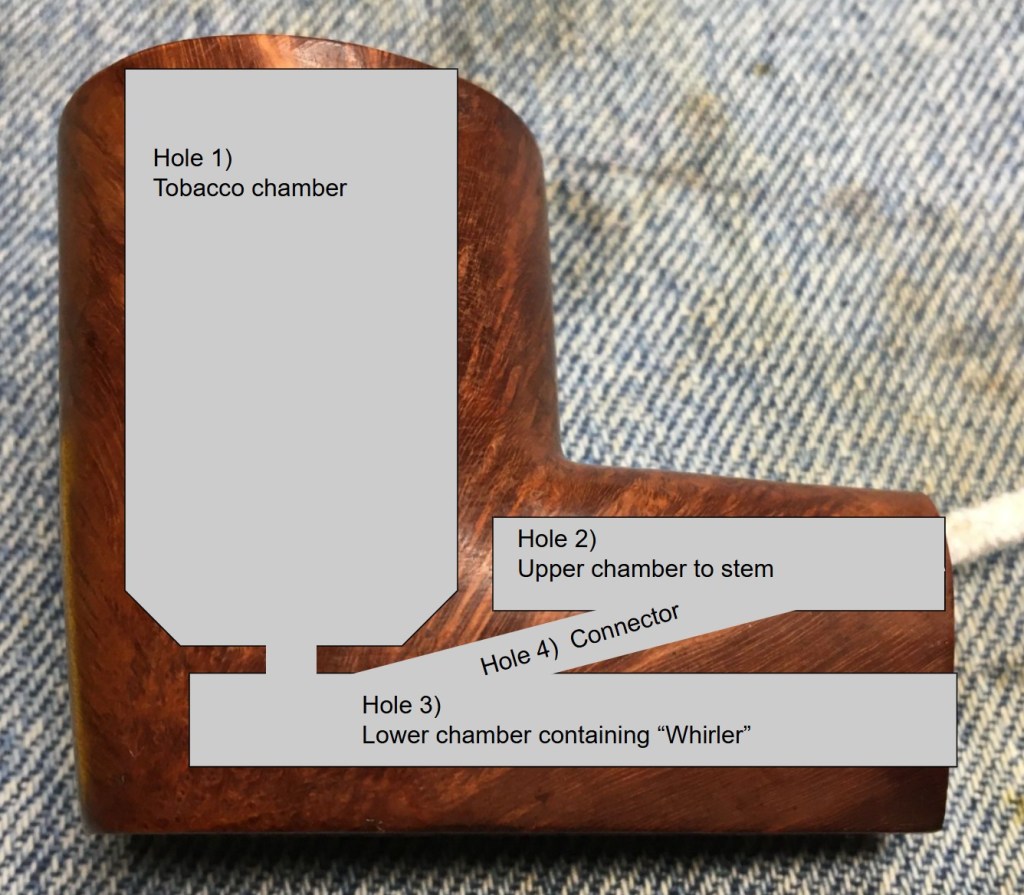

By the early 1930s, there were some concerns about the tars and nicotine found in tobacco smoke. In order to mellow out the flavor of hot tobacco smoke as well as to capture the tars and nicotine, the S.M. Frank & Co. introduced the Medico pipe filter. This is an absorbent paper filter that many people still use to this day. In order to accommodate the new filter, the company developed an accompanying brand of pipes known as Medico. That line of pipes continues in production today.

The company ended up buying some of their main competition in 1955. That year the Kaywoodie brands came under the S.M. Frank Company. The Medico brand continued production through this transition without many changes. The next big change for the brand came in the late 1960s. In 1966, the company developed a synthetic material that combined the traditional briar wood with resins. It is known as Brylon. At that time, all Medico pipes were made from imported briar wood. In order to keep production costs down, the company began offering some lines with Brylon. Today, that is still true.

Today, the Medico brand of pipes is still a top selling one for the S.M Frank & Co. This line of pipes comes in thirteen different finishes with five made of briar wood and the rest from Brylon. All come with the push bit with a filter inside. The filter is easily changed out when the smoker desires. In the briar wood finishes, this line includes the Silver Crest, Premier, Bold Rebel, Kensington, and Windsor. In the Brylon, the line includes the Lancer, Apollo, Standard, Varsity, Conqueror, Medalist, Cavalier, and V.E.Q. As far as price, the briar wood pipes tend to be higher in cost that the Brylon ones.” (Medico Pipes History | TobaccoPipes.com)

The days of “drug store pipes” are apparently over. I typed in the following question:

“Are Medico tobacco pipes sold at physical Walmart, Walgreen’s or drug stores anymore?”

Here is the answer Google gave:

Next I typed in, “Where can I buy a new Medico tobacco pipe?” into Google and got this:

Clicking the first link, Medico Pipes Exclusive Full Line Retailer!!!, took me to a remarkably blank page where not a single pipe was listed. Now please do not think that I am speaking ill of WVSmokshop.com, I have ordered from them and will continue to order from them. They are the only retailer where I can find Captain Black Copper which is a favorite aromatic of mine. The fact remains, Medico pipes are not readily available outside of the used or estate market. As for when this particular Medico Medalist was produced, I cannot say with certainty. I would hazard a guess between 1960-1980.

The Restoration

The Medalist made it from the photo table to the workbench minus the used filter from the stem.

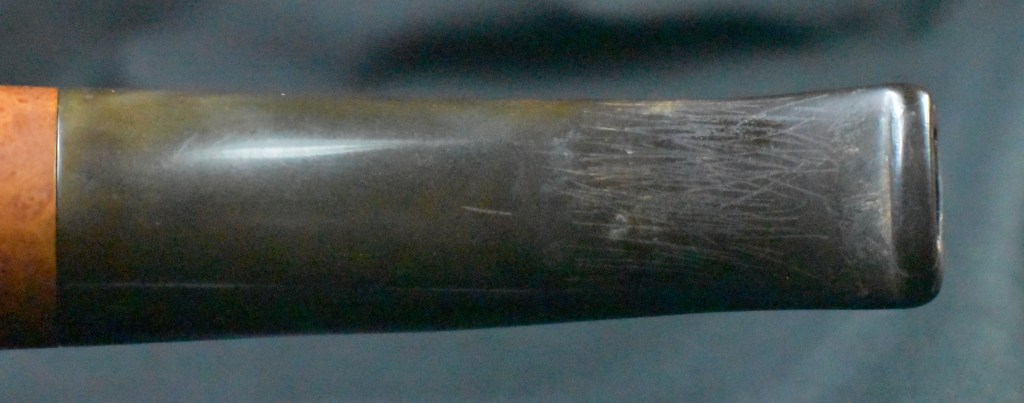

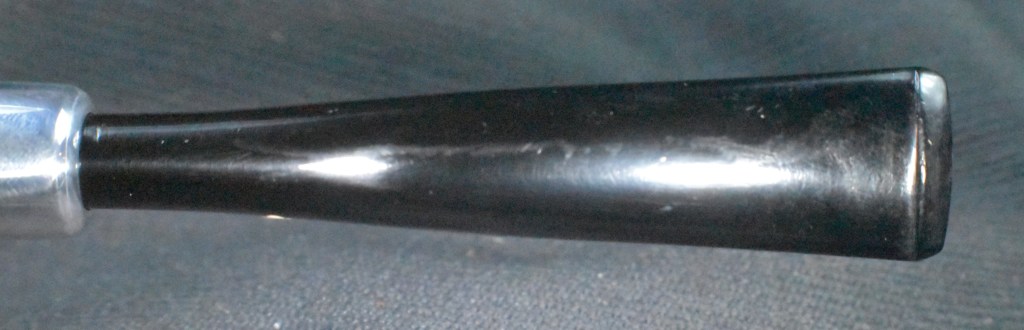

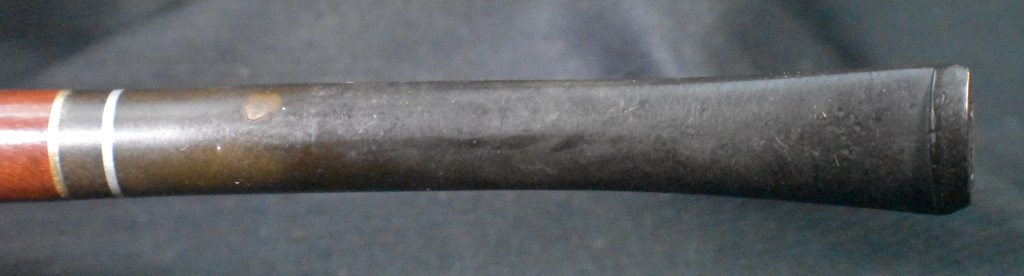

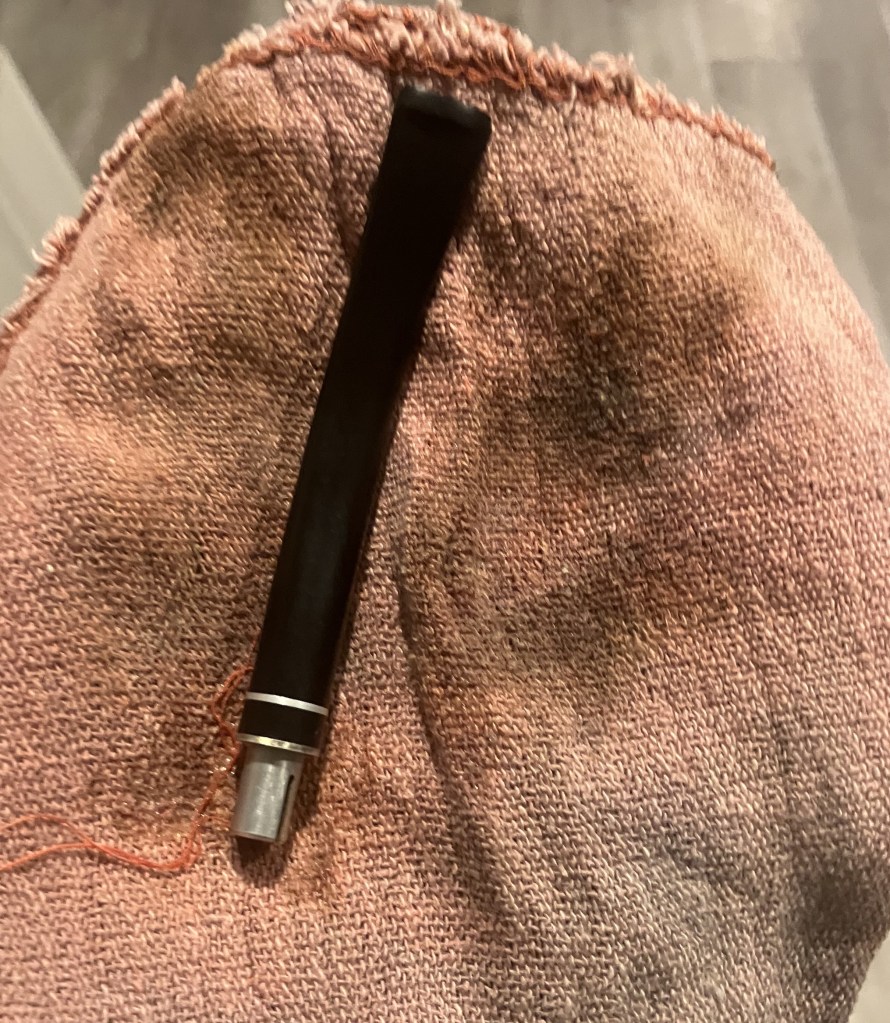

I started with the stem. There was tooth chatter on both the top and bottom surface of the bite zone.

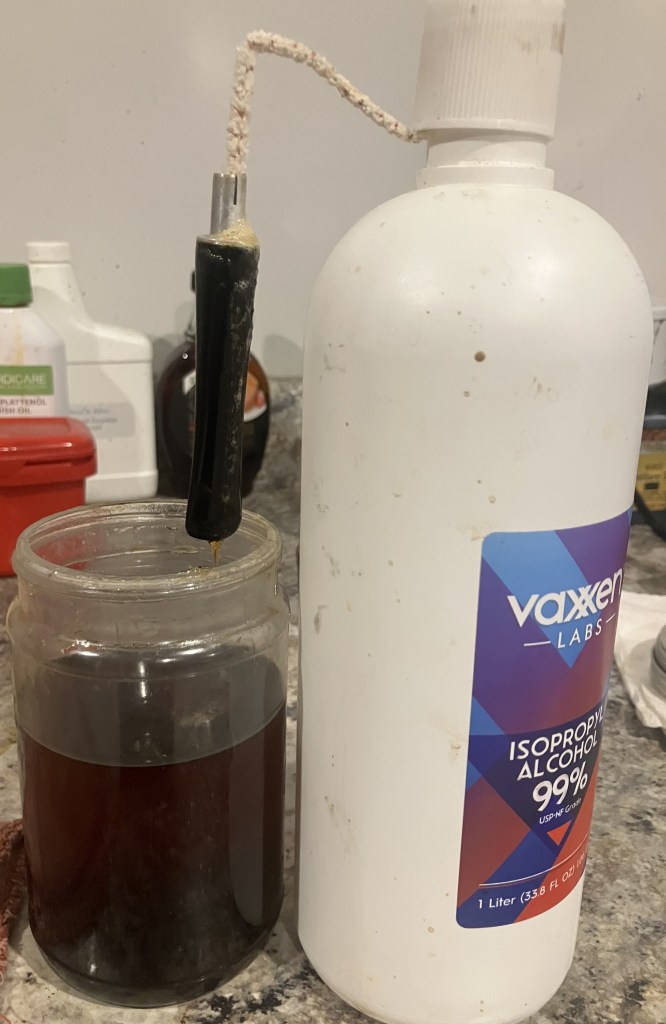

The interior of the stem was cleaned with 99% ethyl alcohol on cotton swabs and bristle pipe cleaners.

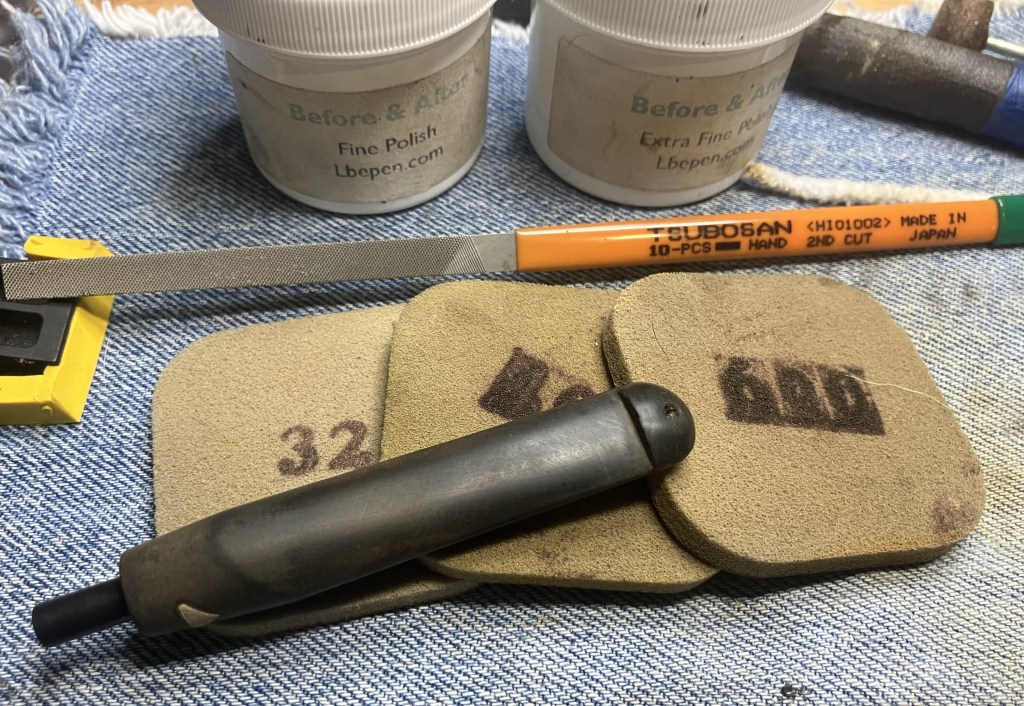

The tooth chatter was filed with a small flat file.

I scrubbed the stem with Soft Scrub cleanser on make-up pads. Usually I do this after soaking a stem in a deoxidizing solution, I do not know why I’d always used that order, deox first the scrubbing.

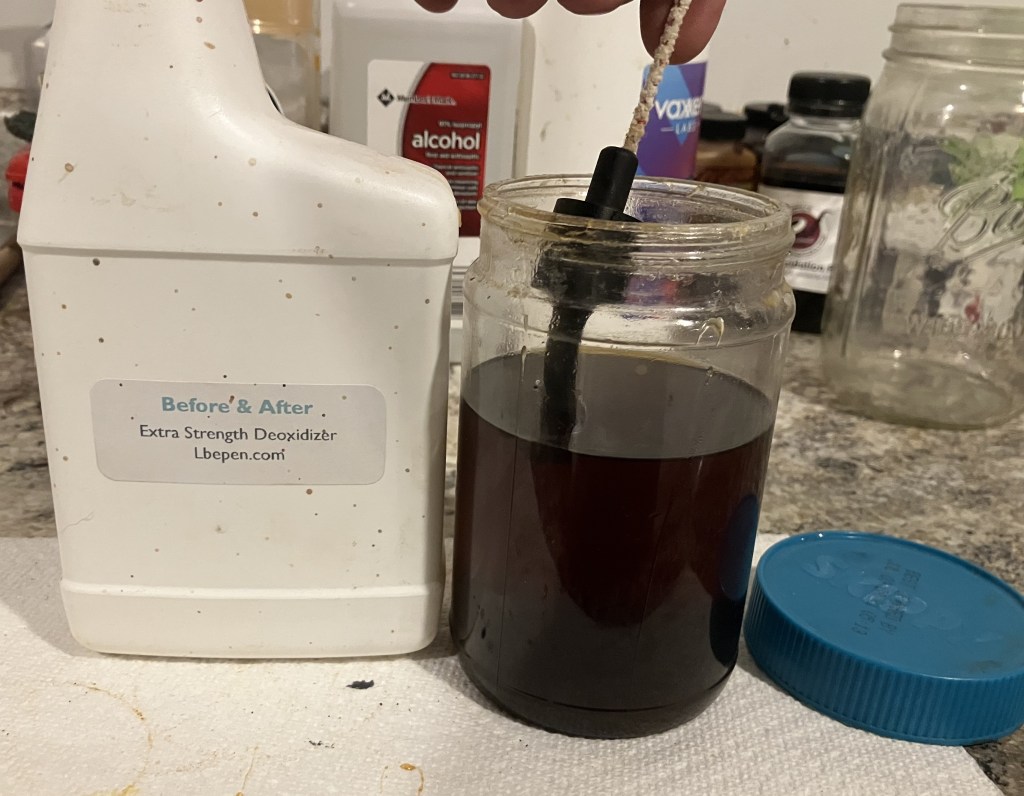

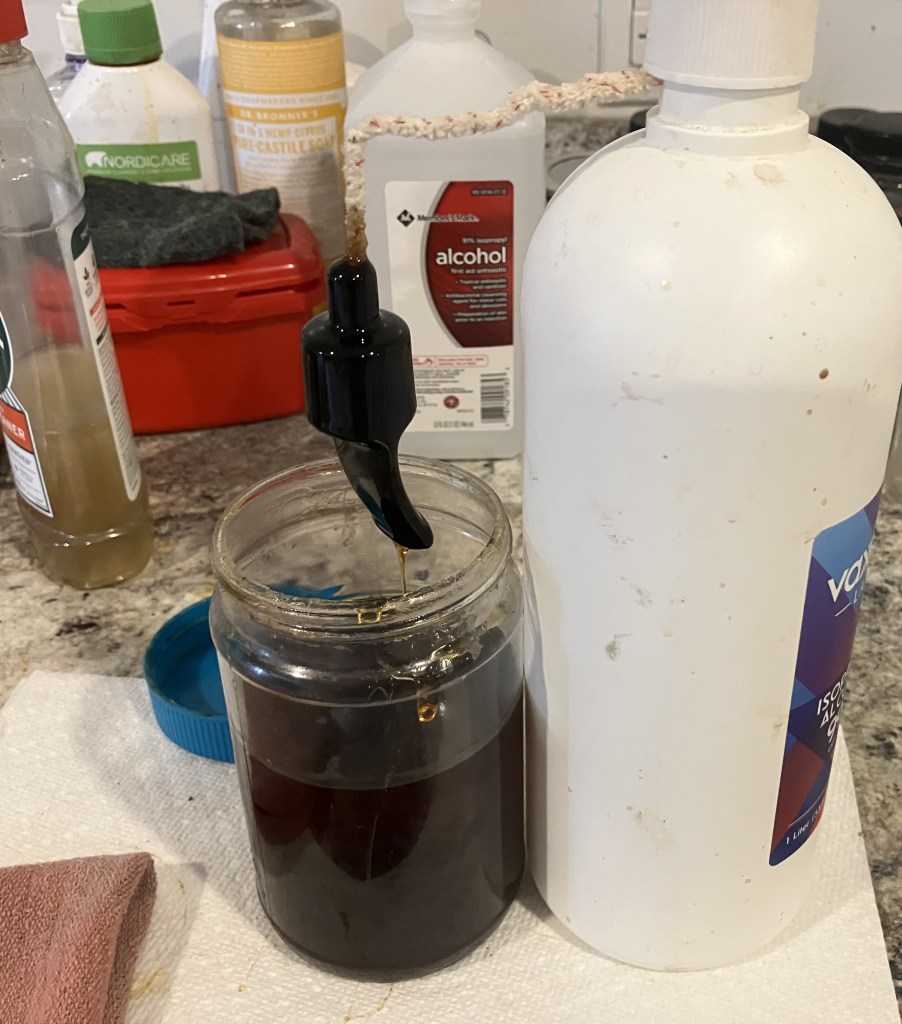

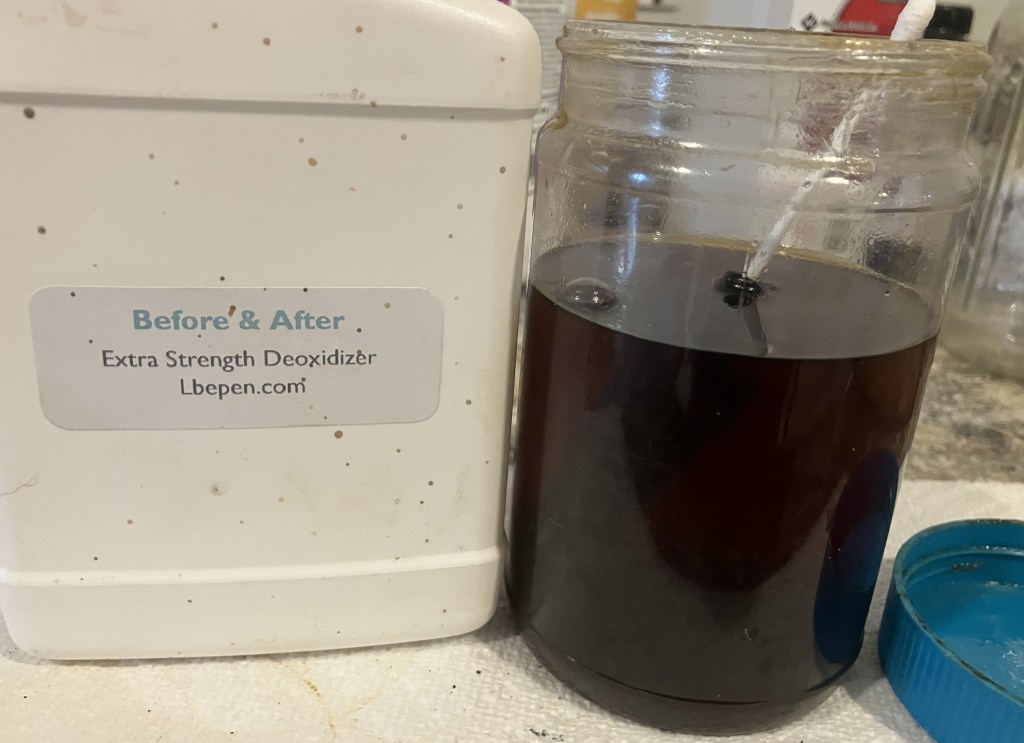

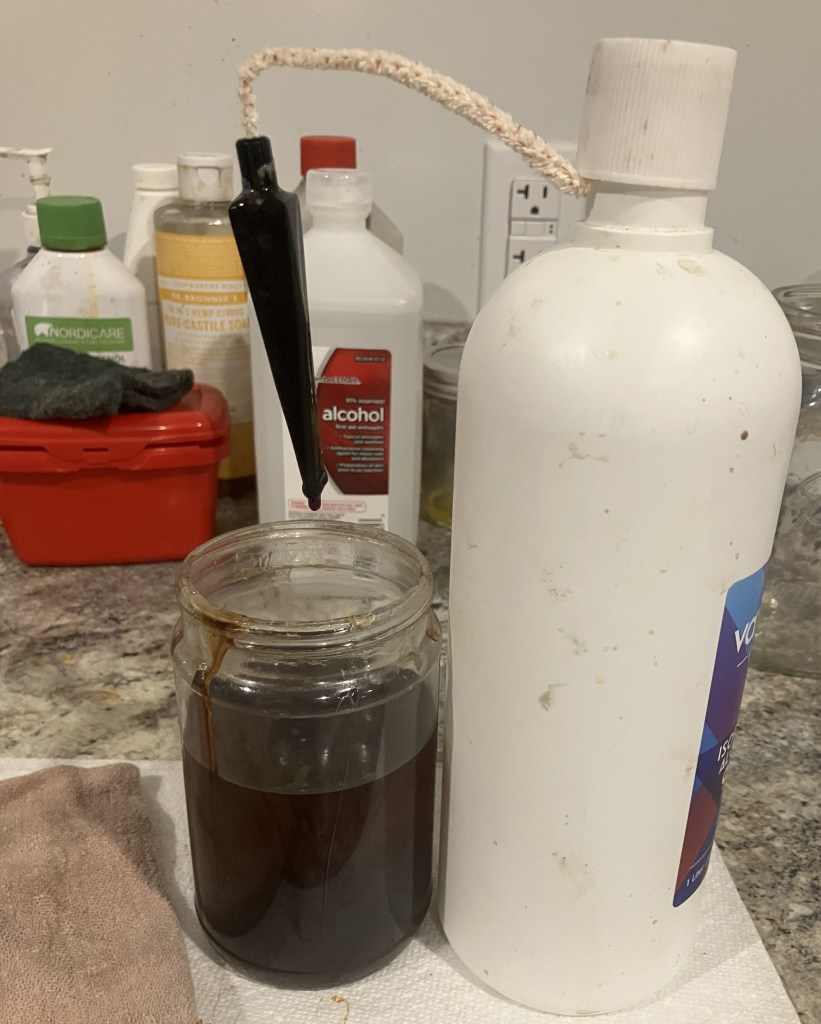

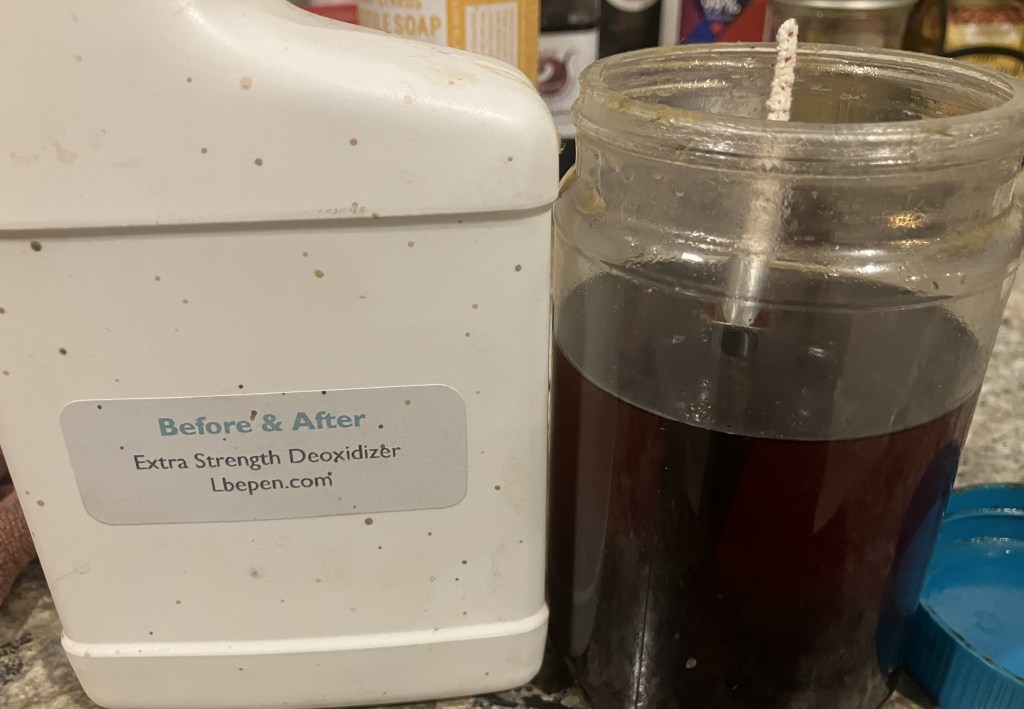

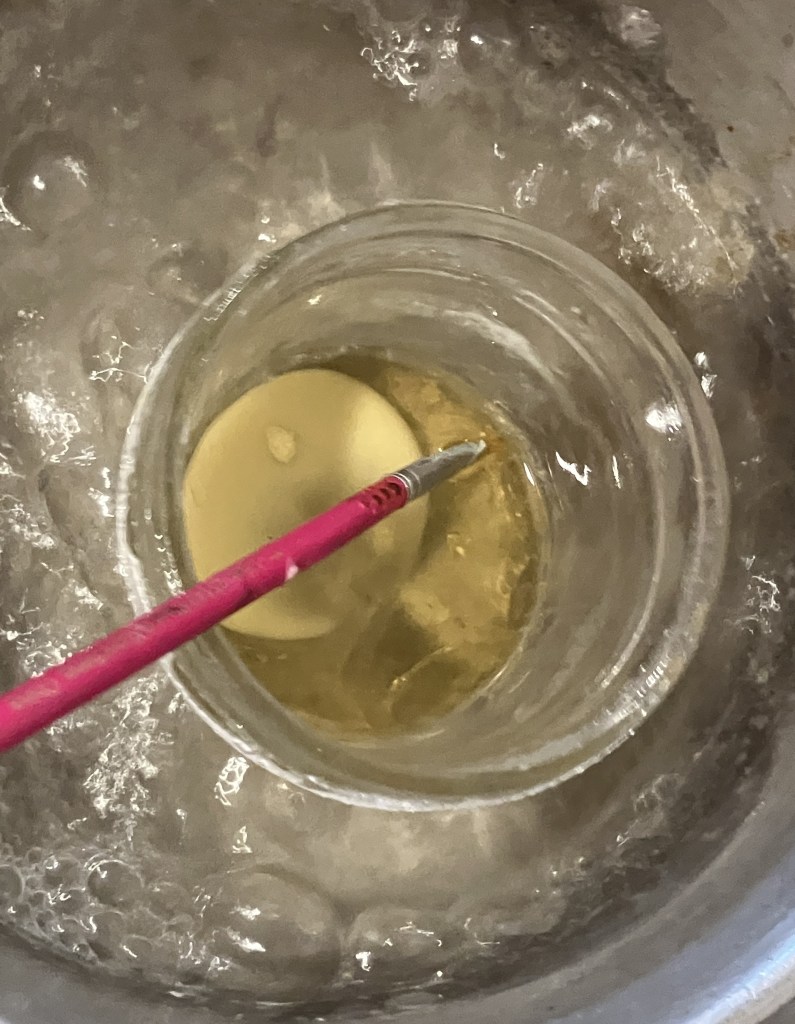

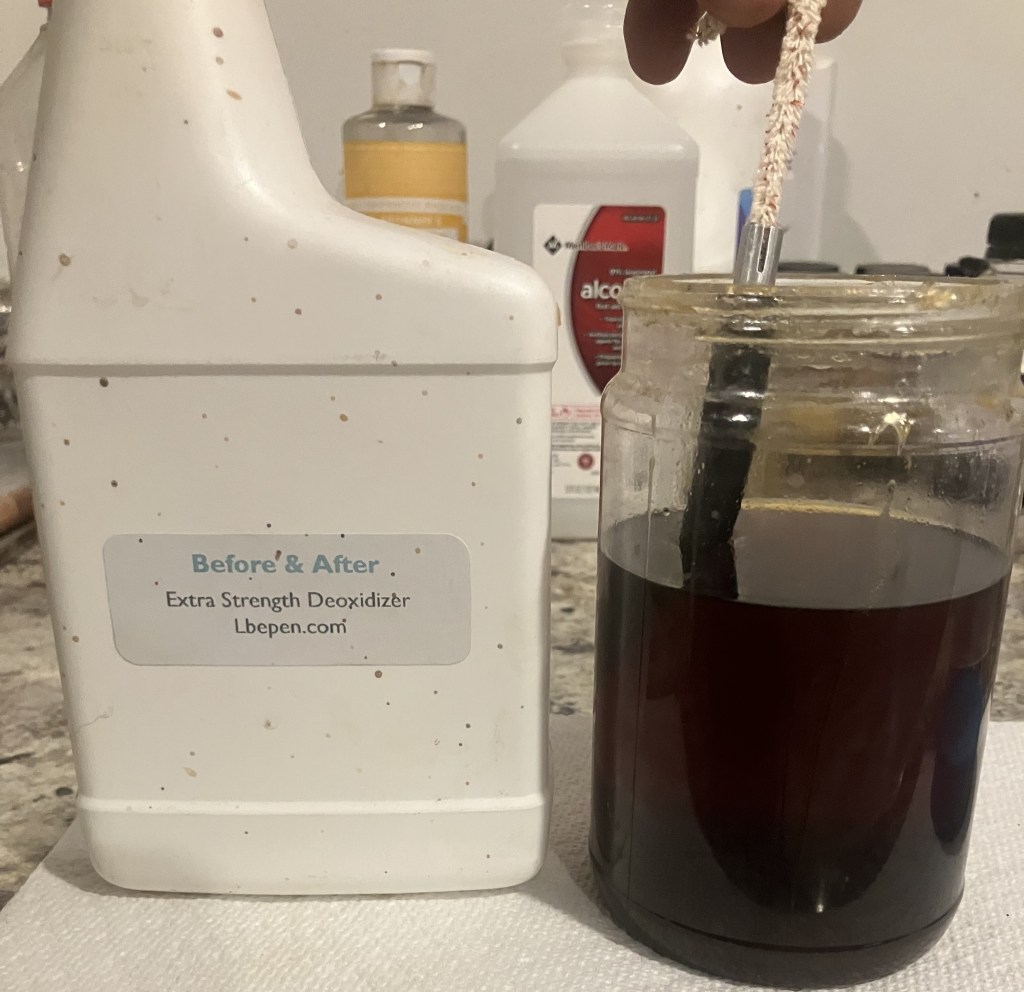

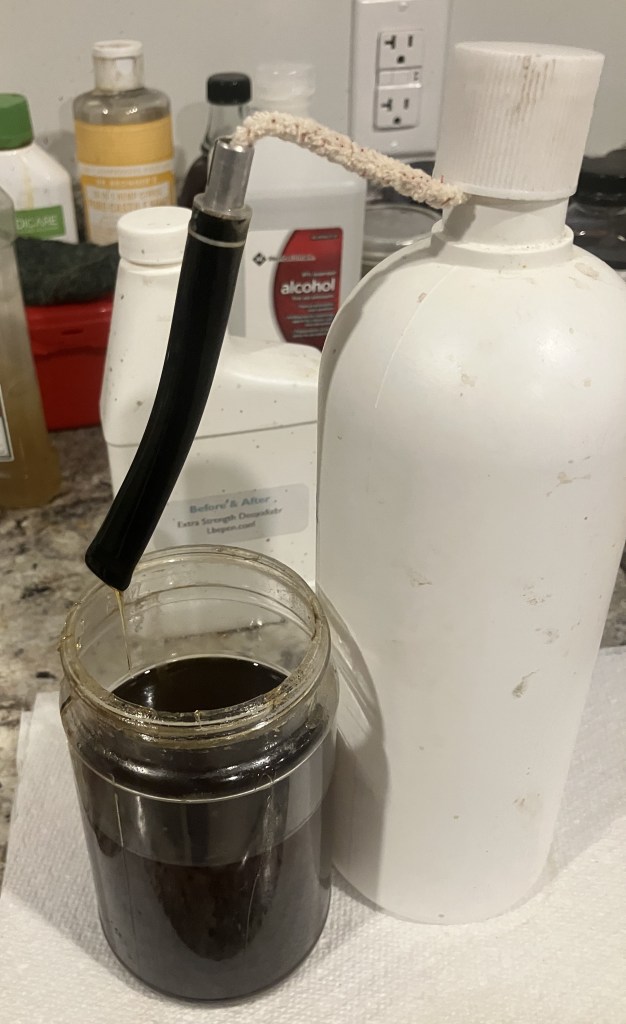

After the Soft Scrub I suspended the stem into Before and After Extra Strength Deoxidizer. I left the stem in the solution for 2-3 hours.

I turned my attention to the reaming of the tobacco chamber.

The PipNet and the #2 blade did this quickly with the Smokingpipes Low Country reamer doing some cleanup.

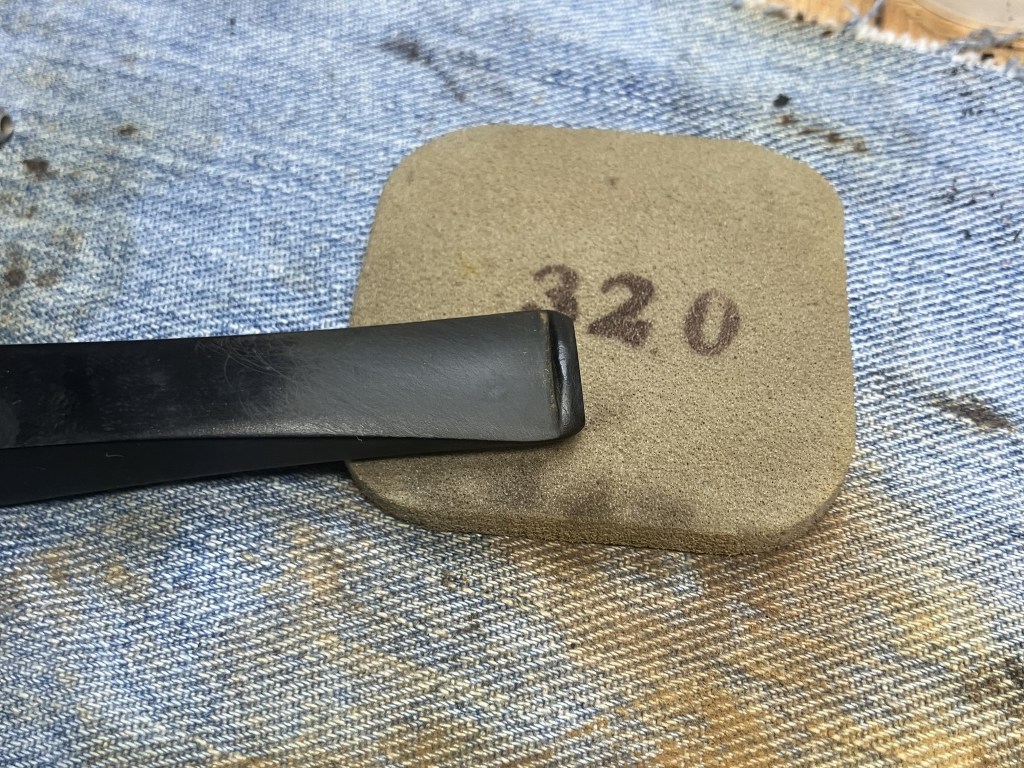

The chamber looked good. Next, I sanded the tobacco chamber with 320 sandpaper wrapped around a wood dowel. There was no damage to the chamber from heat.

I cleaned the shank with alcohol, cotton swabs and bristle pipe cleaners along with some scraping with a dental scraper.

I scrubbed the stummel with undiluted Murphy Oil Soap and a nylon brush over the sink. The soap was rinsed with warm water and the stummel dried with a cotton hand towel.

Back at the workbench the stummel looked clean but was coated with a clear coat finish. I am not a fan of clear coat finishes, so it had to go.

Having already used 99% ethyl alcohol, I knew the finish was impervious to that solvent. I tried acetone on a cotton swab to see if it would dissolve the finish. I did.

To save myself time, I placed the stummel into a jar with acetone and let it soak for 20 minutes.

The stummel was removed and wiped with a paper towel. The vast majority of the finish had been removed.

I used acetone on make-up pads to scrub most of the remaining finish from the briar.

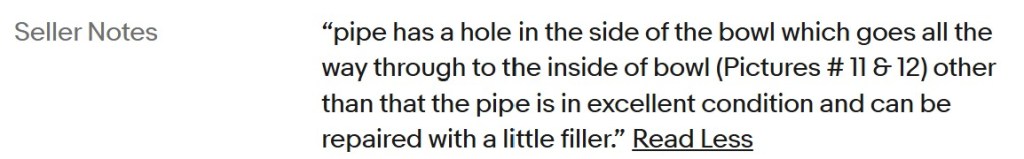

The acetone had softened the worst of the fills. I used a fly tying bodkin to pick the old fill material from the stummel.

A light sanding with a 320 sanding sponge and another wiping with acetone and the clear coat was gone.

In preparation for the sanding, I covered the stamping with masking tape.

The finish free rim looked like it could use a light topping.

A few figure eights on a piece of 400 grit sandpaper laid on the countertop.

The one fill to rework was refilled and packed with briar dust.

To this dust , I added a tiny drop of Thin cyanoacrylate (CA, super glue). The thin mixture penetrates and bonds the dust to the briar.

The new fill was filed then sanded smooth.

After a couple of hours’ish, I pulled the stem from the deox and let the excess solution drip back into the jar for a few minutes.

The stem was then vigorously rubbed with a coarse shop rag to absorb the remaining solution and abrade the softened oxidized rubber. This scrubbing the stem with Soft Scrub before the deox, will need more experimentation, but it seemed to work better.

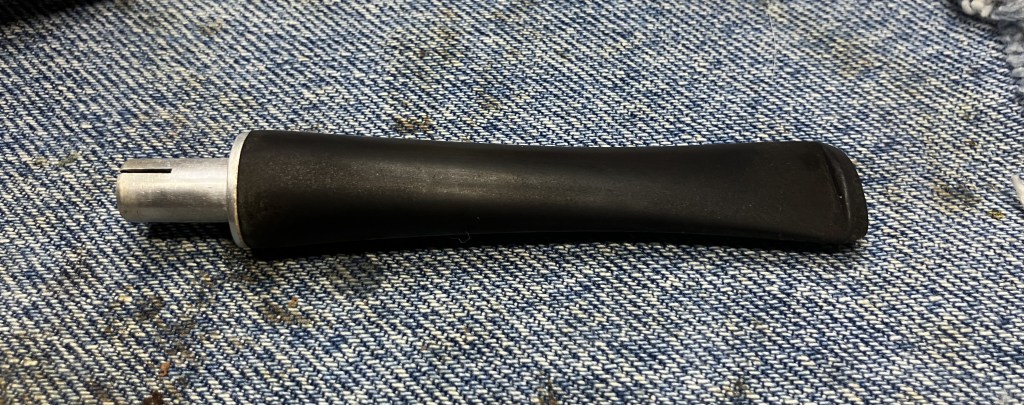

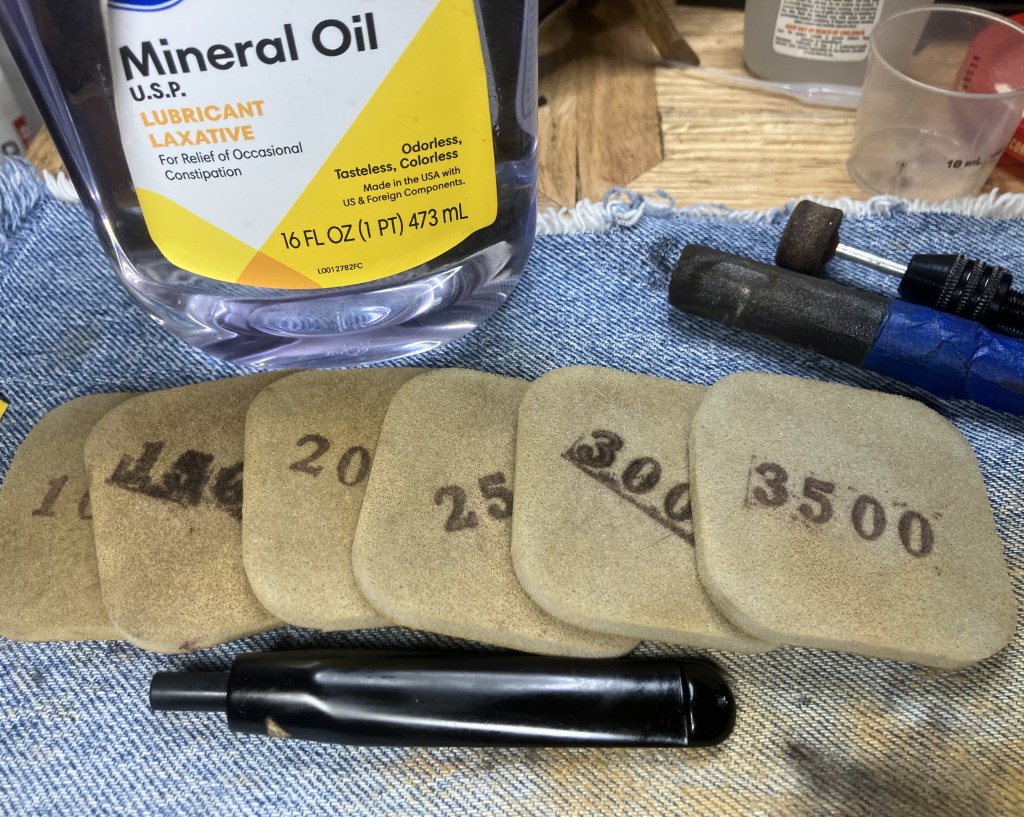

The stem was lightly sanded then rubbed with mineral oil. It looked pretty darn good.

The pipe was reassembled and sanded, intact, with a series of sanding sponges 320-1500 grit. The stummel was wiped with a make-up pad wetted with alcohol between sponges while the stem was rubbed with mineral oil and wiped with a paper towel. Both wipings were to remove sanding debris.

The sanding continued with 2000-3500 grit sponges and repeated wipings between each sponge.

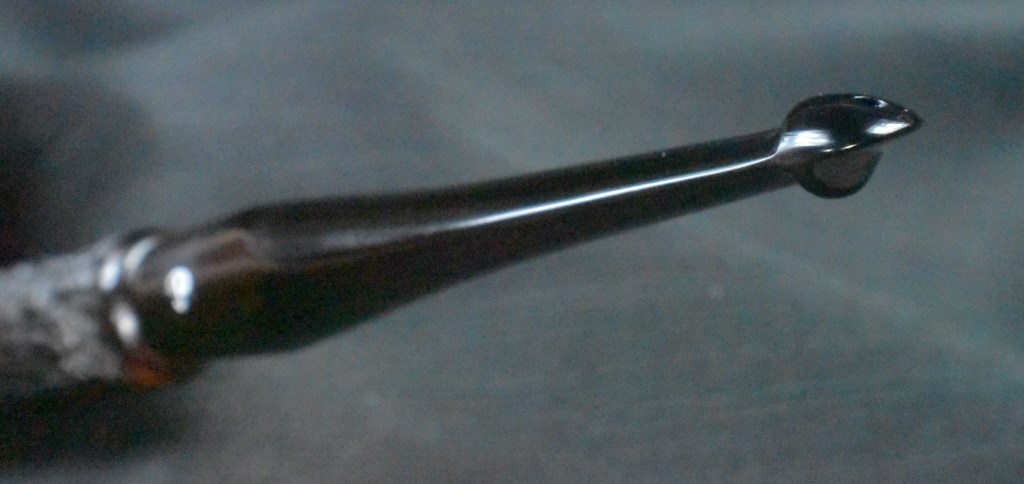

The pipe was then worked with micro-mesh pads 4000-12000, again the whipping between pads. I will add that instead of mineral oil I used Obsidian Oil on the stem.

A coating of Before and After Restoration Balm was applied to the briar and allowed to sit for 20 minutes.

An inside out athletic sock was used to hand buff the stummel and remove excess balm.

The stamps were re-masked with fresh masking tape to protect the stamps from buffing.

The pipe was then buffed using white buffing compound.

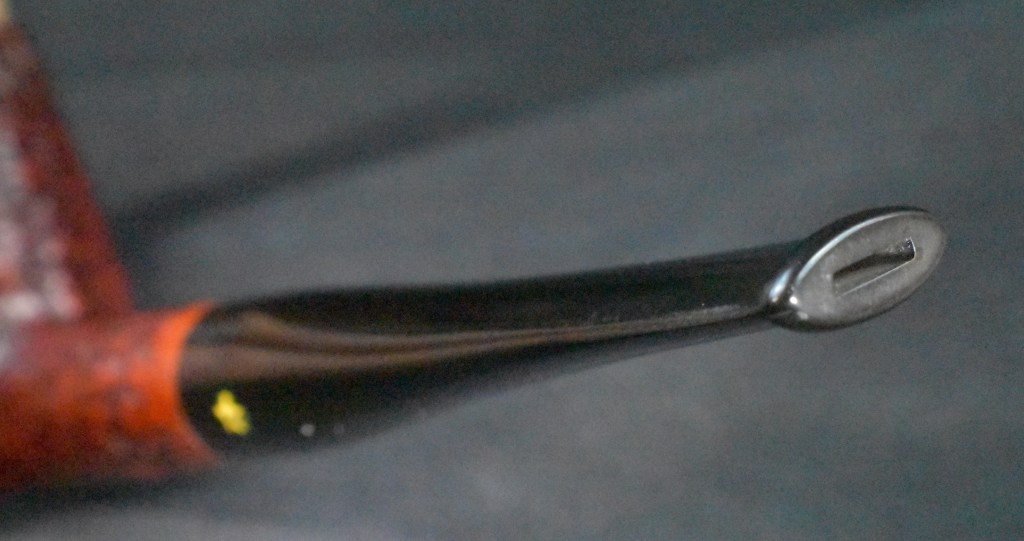

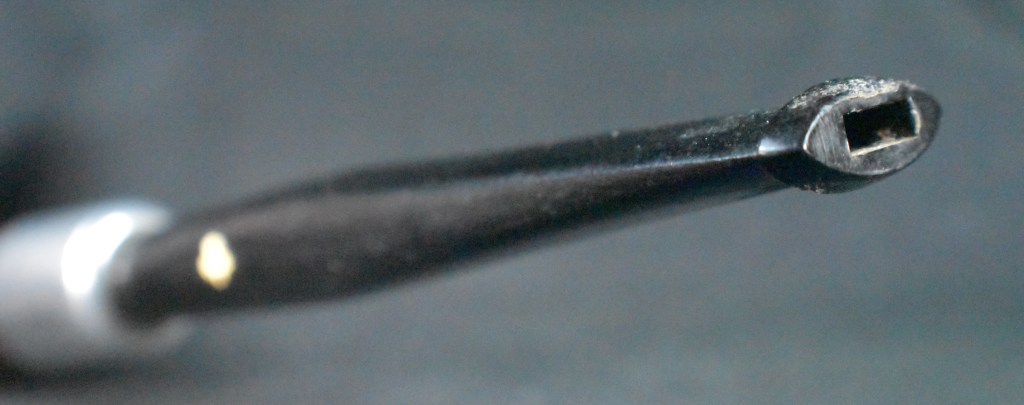

The M logo on the stem had lost it’s paint and some of detail during the deoxidation. I used a white acrylic model paint to repaint the logo.

The results were not as good as the original but the loss of detail was the price of deoxidation.

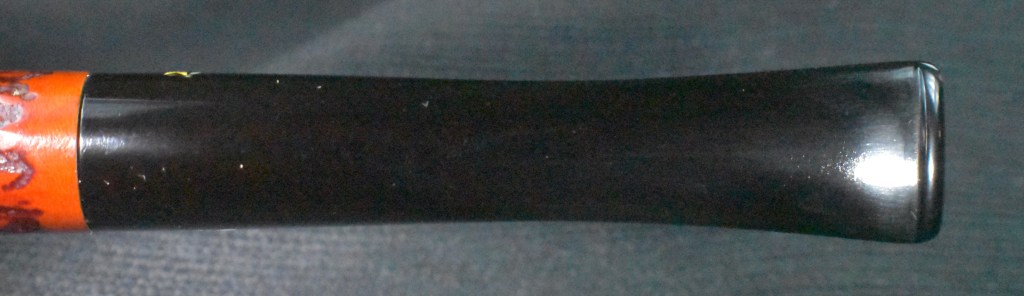

The pipe then received several coats of carnauba wax from the buffer.

The final step was hand buffing with a microfiber polishing cloth.

I think this Medico Medalist turned out quite well. I love the author shape and am reminded to use an author off the rack when writing blogs. The briar grain of this pipe is pretty but I wonder if I should have given it a contrast dye. That might have made the existing bird’s eyes stand out better. The grain is still very nice for a drug store pipe. The stem polished up very well and the glossy black does accentuate the existing briar grain well. The dimensions of this Medico Gold Crest meerschaum apple are:

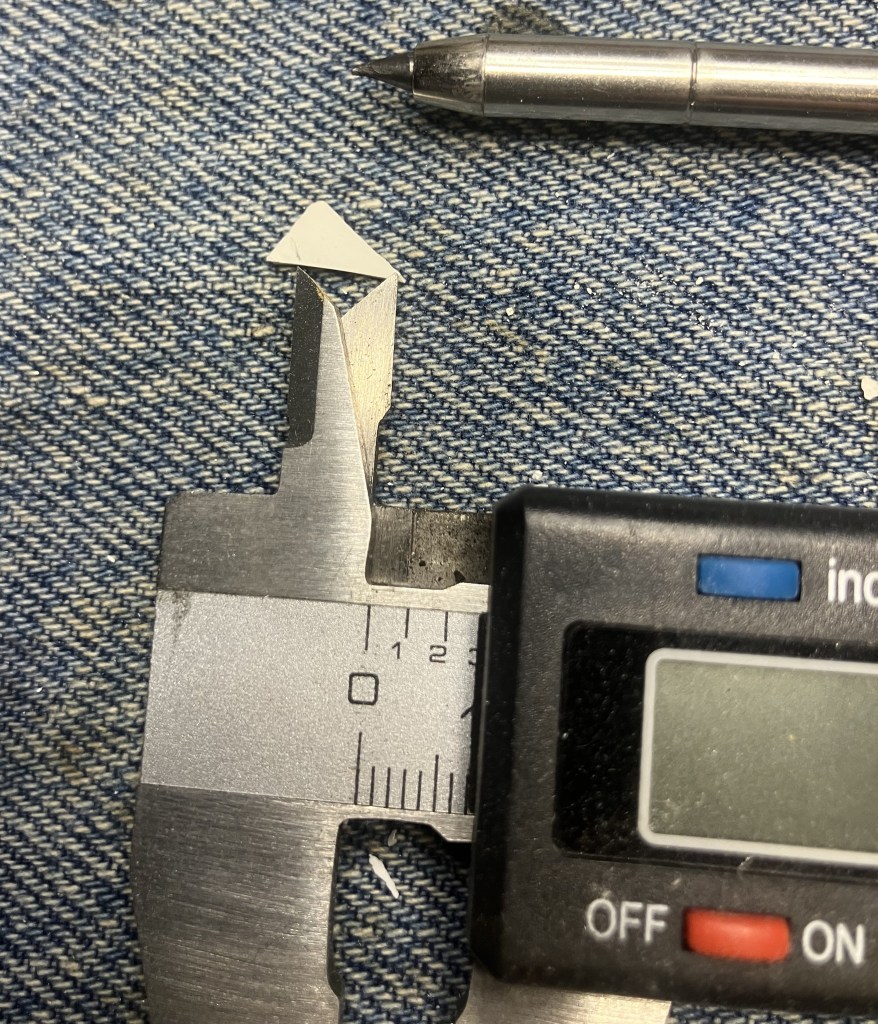

- Length: 6.30 in./ 160.02 mm.

- Weight: 0.96 oz./ 27.22 g.

- Bowl Height: 1.29 in./ 32.77 mm.

- Chamber Depth: 1.07 in./ 27.18 mm.

- Chamber Diameter: 0.71 in./ 18.03 mm.

- Outside Diameter: 1.53 in./ 38.86 mm.

I do hope that you have found something here useful to your own pipe care, maintenance or restorations. If you like this sort of thing, please click the like and subscribe buttons. Thank you for reading the ramblings of an old pipe lover.

Below are some photos of the finished Medico Medalist Author.