Written and photographed by

John m. Young

I still appear to be stuck in the 1940s. Maybe stuck is the wrong term, that sounds a bit negative. How about focusing on the 1940s? That sounds better. This restoration is all about this lovely lovat from Danco. A beautiful little pipe won from eBay to further satisfy my quest for post-WWII artifacts.

Advertisements like this are what first drew me to Danco. “ Where There’s Smoke – There’s Danco”.

(Pipe Lovers Magazine 1947 all numbers : Free Download, Borrow, and Streaming : Internet Archive volume 1, p. 23)

This large ¾ page advertisement was still working some 77 years after the original publication. Well, I had the Danco in hand yet I wanted to know more about the company. Pipedia.org had little to offer in the history of Danco. The short entry is as follows:

“Some references to Danco pipes from the book “Who Made That Pipe?” and they put the manufacture of them in both Denmark and the US but do not attribute it to any specific maker. The adsn right indicate the location of the firm was on Hudson St., in New York.

Some Danco pipes are marked “Imported Briar” and that would suggest they are American made.

Some Danco pipes that are marked “Italy” so the US Danco distributor/seller must have had some of the briar pipes they sold made in Italy.

Danish Dancos should be stamped “Denmark.“

” (https://pipedia.org/wiki/Danco)

Hmm, not much on a company that obviously had some market share, enough to warrant ad space in a nationally distributed magazine, anyway. Next stop was to pipehil.eu, let’s see what they have to say. Nothing. That can’t be right. Hmm, how about a blind search for “Danco” on Google. Hmm, the pipedia.org page, an eBay listing and Steve Laug’s Rebornpipes.com. I checked the Rebornpipes.com blog post and discovered that Steve had apparently experienced the same lack of historical context as I had. Disappointed, I expanded the search to include “Danco pipes, New York, New York”. Scrolling through those results I came across a receipt.

(https://i.ebayimg.com/images/g/Y5EAAOSwotVka4-5/s-l1600.jpg)

Evidence that Danco did exist. Other than the pipe in hand, a pipedia blurb and a restoration by Steve Laug. This led to a search for the Frankle Brothers Company.

(https://metromonthly.wordpress.com/2013/03/14/photo-frankle-bros-in-downtown-youngstown/)

(https://twitter.com/JoshLipnik/status/1423823946416377859)

Well, they too did exist. Apparently “did” was the key word. Conjecture says that the first store was older than the second and neither remain today.

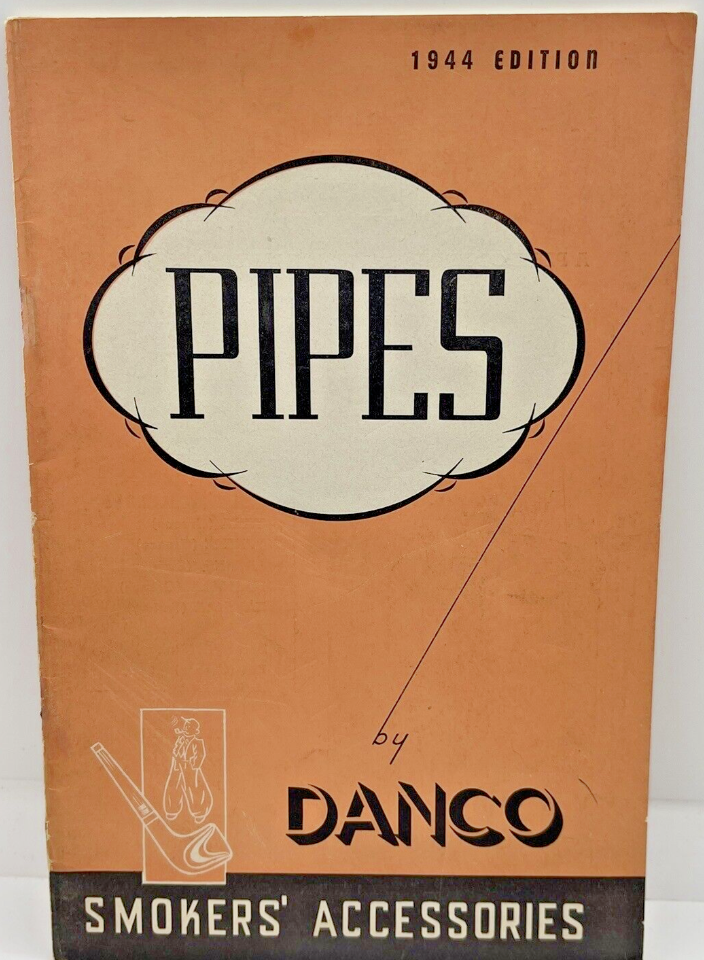

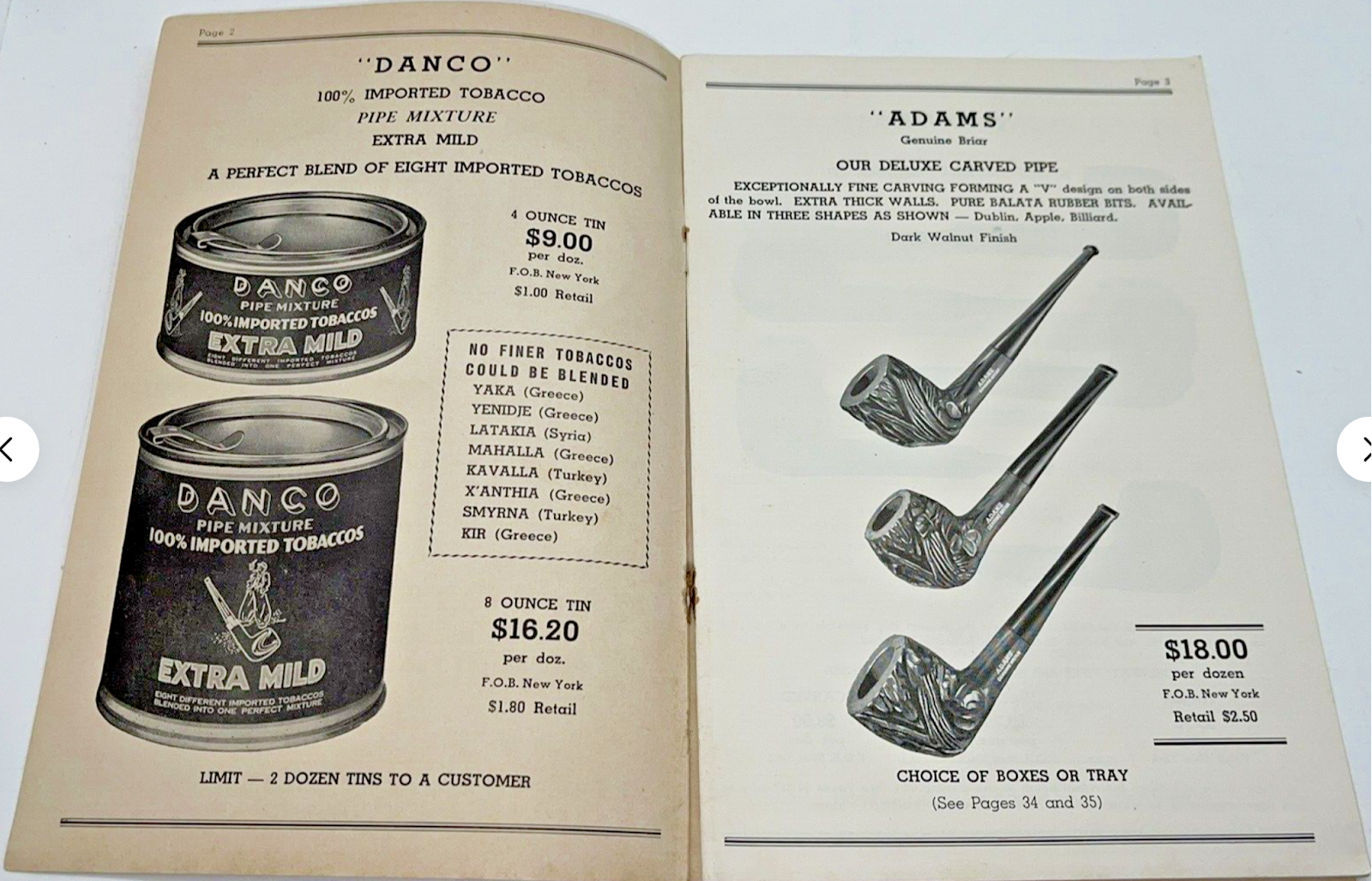

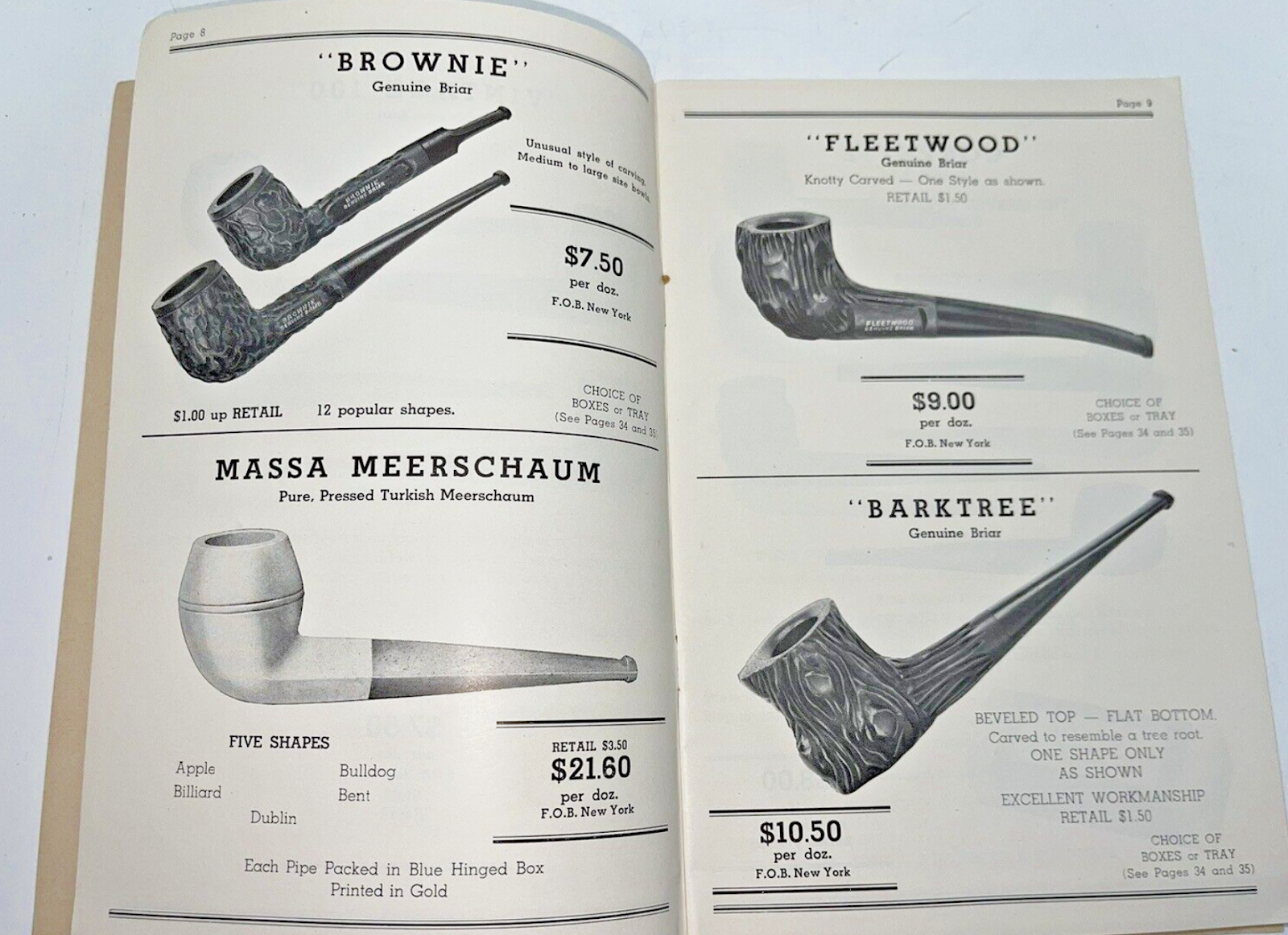

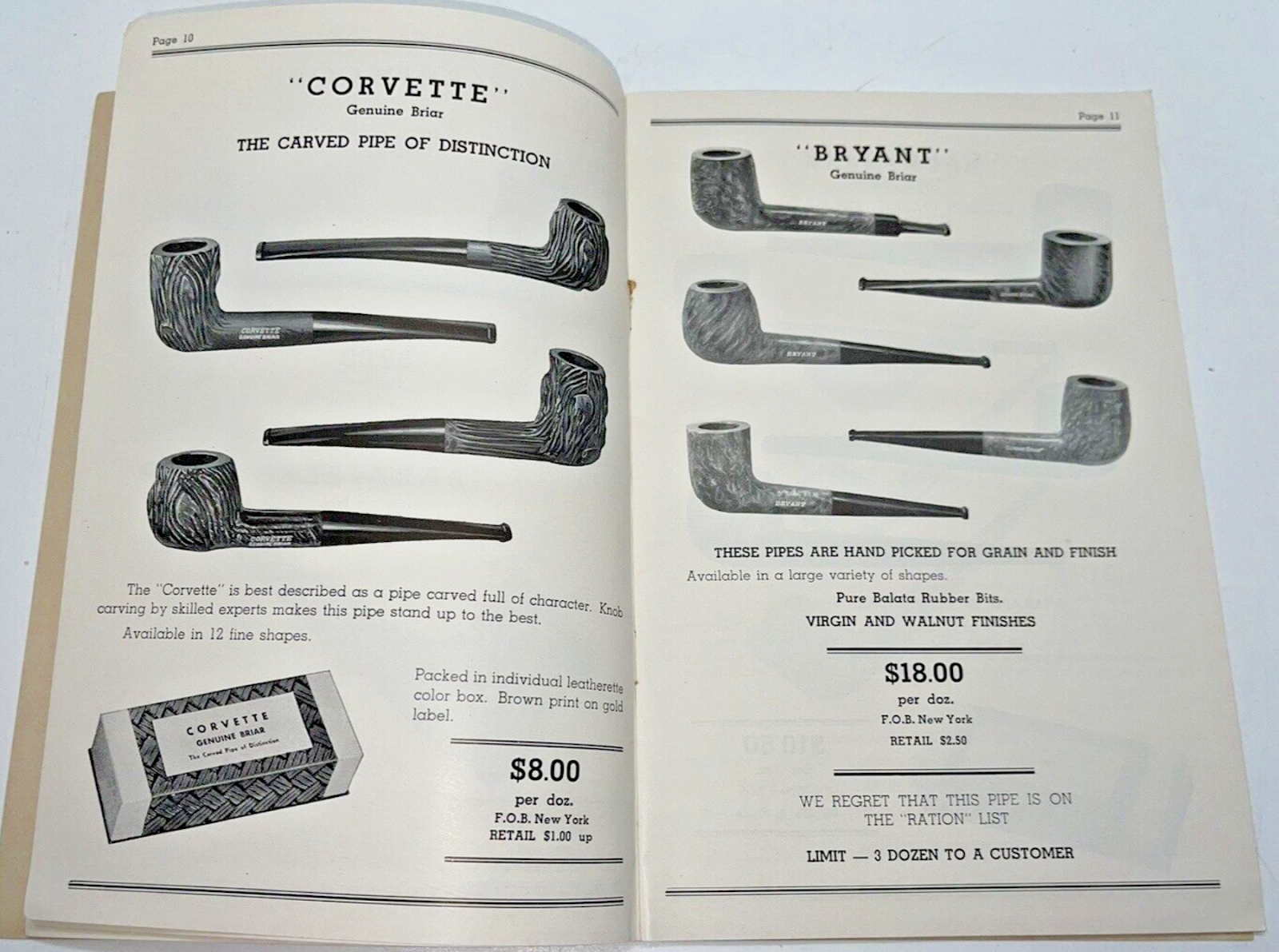

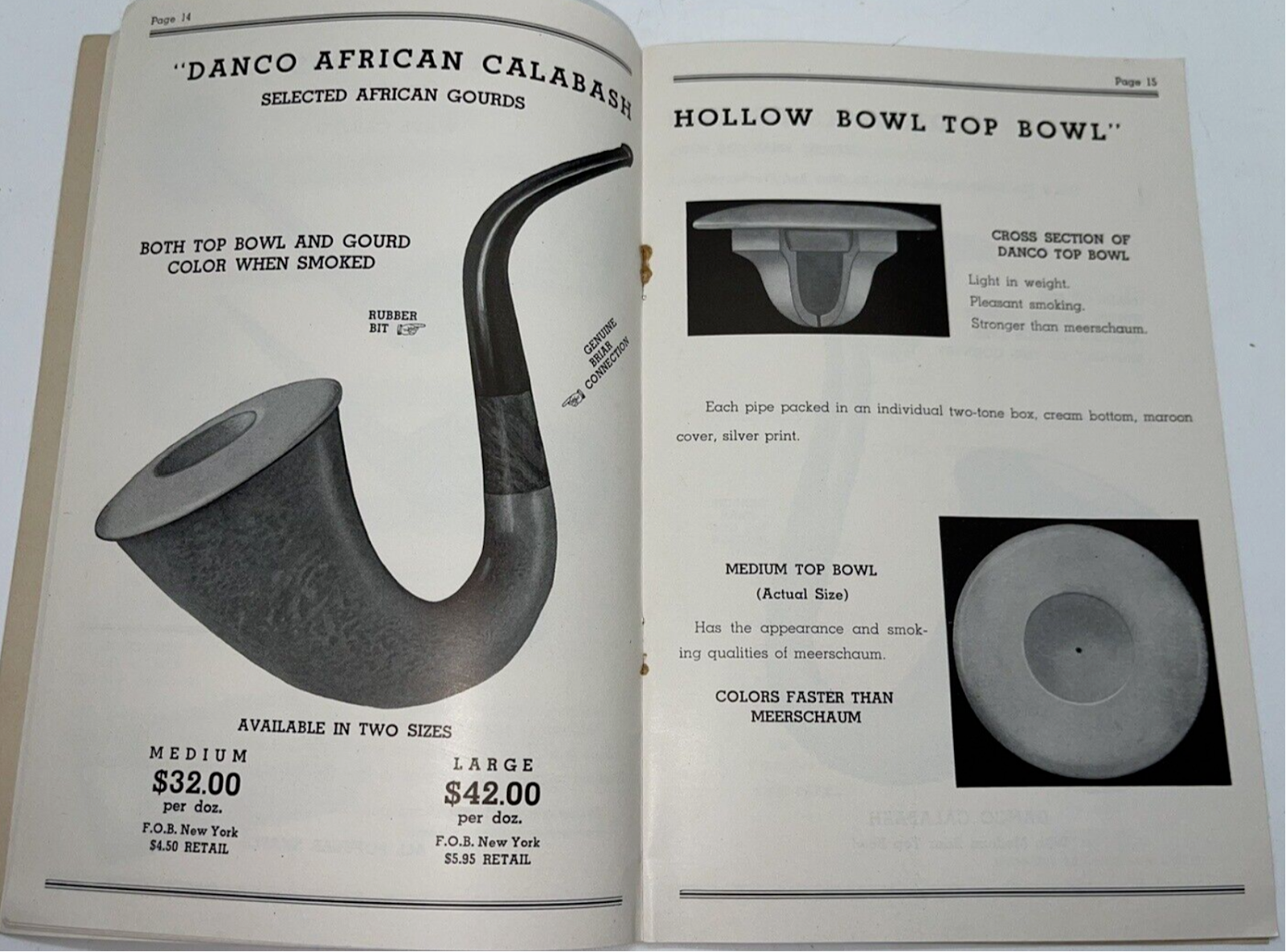

Being innately stubborn I refused to give up. I tried the eBay link. Okay, that’s cool. An original 1944 multi page catalog. Obviously, a catalog meant for retailers buying pipes to sell at their shops and not a catalog for the consumer. It even came with caricatures of Hitler, Hirohito and Mussolini.

Front and back covers

Well, I am not sure how to credit the original source material of screen shots of auction items from eBay so, there’s the link. If any lawyers come around asking, you don’t know anything, okay? I mean these images were obviously put here by some Antarctican hacker attempting to interfere with democracy.

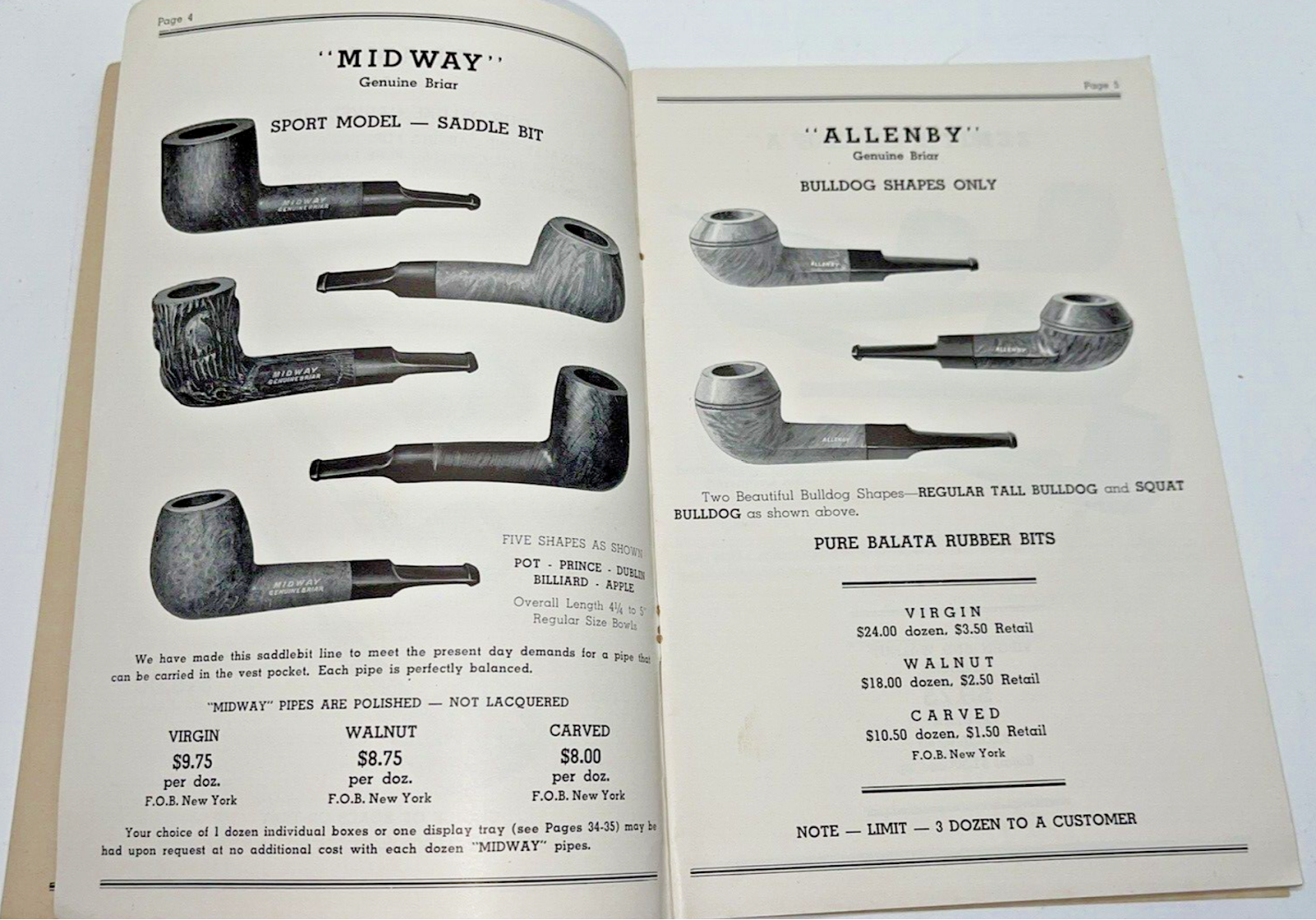

The greatest let down of this whole research project has been the lack of information about the Danco Lovat sitting here next to me. The catalog doesn’t even mention a lovat as a shape made by Danco. At best, you could say page 4 has a “Sport model” “Billiard” that looks about the same. All of the pipes in the catalog have a model/line associated with them. Perhaps this pipe did as well but, the stamp below “Danco” is far too faint to know if there ever was a stamp there. So let’s assume that this is a 1940’s Danco lovat. Besides, that saves me the trouble of retitling this blog.

Here is what the pipe looked like upon arriving here in southeast Nebraska.

The Danco was in very good shape for a used 70+ year old pipe. I thought the list of tasks would include reaming, airway cleaning, general cleaning, sanding, pit removal/refilling/filling, more sanding, micro-meshing, polish and wax. A very standard restoration.

I started with a new work surface denim piece, a disassembled pipe and the reaming tools; PipNet with a #2 blade, Smokingpipes Low Country knife and the General triangular scraper. Of course there was the ever-present medicine cup with 99% isopropyl alcohol and cotton swabs. I could not get the aluminum stinger free from the stem. This made cleaning a bit more difficult but still doable.

The reaming was quick and easy due to there being nearly no cake present. Most of the work was done with the General scraper. After reaming the interior of the tobacco chamber was sanded using 220 sandpaper wrapped around a wood dowel.

Next I started cleaning the airway of the shank. I used several cotton swabs dipped in alcohol to scrub the airway. The effect of this was to slightly soften the tar and yuck (very technical pipe restoration term referring to undesirable deposits, usually black or dark brown in color and well, just yucky). With the tobacco chamber being so clean I had no reason to think the shank would be this bad. It was. I repeated the following process:

- Pour 3 ml of alcohol into the bowl. Allow the alcohol to flow into the shank.

- Spill a little bit of the alcohol onto my jeans

- Hold the stummel so the alcohol won’t spill.

- Scrub using a nylon shank brush with the alcohol.

- Use cotton swabs to absorb the remaining alcohol while scrubbing airway (this usually took 3-4 swabs)

- Repeat.

Oh yeah, I forgot to say, get frustrated after about the 5 repetition and wrap a 2 inch x 2 inch piece of paper towel around the round needle file and scrub with that too.

Once I had emptied the box of cotton swabs and did not seem to be making any progress, I started to scrape the airway with a dental scraper then did the above steps 1-6.

Being the person responsible to keep America’s cotton farmers and paper stick manufacturers going in these difficult economic times is a burden that I am willing to accept. And, it may serve as time off of my sentence for the illegal crediting of source material for the Danco catalog. Eventually the shank was cleaned.

I then turned my efforts to cleaning out the stem. Try as I might, I could not get the stinger out of the stem. I wrapped it with a rag and gripped it with a pliers and tried wiggling and twisting the stem. I feared that applying too much pressure would break the tenon. I surrendered and just cleaned from both ends. The stem was not as bad as the shank had been but it did require several bristle pipe cleaners dipped in alcohol to rid it of the yuck.

With the interior of the stummel cleaned, next was the cleaning of the exterior. This was done with undiluted Murphy’s Oil Soap and a medium stiff toothbrush. I recommend doing this over the sink. I applied the Murphy’s twice for this scrub since the stummel seemed to be very dirty. I rinsed the Murphy’s off with warm water and dried the stummel with a cotton dish towel. What I thought was a layer of finish was actually just a layer of oil, dirt and grime. Once cleaned I returned to the workbench and wiped off the exterior with a make-up pad wetted with 95% ethyl alcohol. The pad was remarkably clean and the stummel had the dry flat look of bare wood.

I was able to see three small pits that I wanted to fill on the left side of the stummel and one on the inside edge of the rim.

For these fill I sanded the area around the pit and for briar dust into the sanding sponge. I then placed a small dab of cyanoacrylate (CA, super glue) onto the pit. I dabbed away most of the CA except that immediately on the pit. I then sanded the area with the sanding sponge. This allowed the briar dust to combine with the CA and fill the pit with CA and briar dust. Together they set up almost instantly and filled the small pits. This technique works well for tiny and small pits. It can be used for larger fills but it will take more than one application of CA. For the depression on the rim, I applied the CA and pushed a pinch of briar dust into the CA. This was then sanded smooth.

With the fill addressed I taped over the stamps with painters tape. I then reinserted the stem thus allowing a better grip on the stem for filing the teeth dents. I first tried to paint them with the flame of a lighter. This is done by moving a flame back and forth over the stem. Obviously, not heating the stem to melting or burning, just a rapid heating and cooling to allow the rubber to “rebound” to more of its original shape. This helped but the stem still required some file work to smooth the dents. I also used the file to smooth the button.

The sanding of the stem and stummel was done using sanding sponges. I worked on the stem with the 320-3500 sanding sponges to smooth the scratches from the filing. The stummel was sanded from the 600-3500. Between each sponge the stummel was wiped with a make-up pad moistened with 99% isopropyl alcohol. The stem was rubbed with a drop of mineral oil from my finger and wiped with a paper towel. Once finished with the sanding sponges I removed the painters tape and wiped away residual adhesive from the tape with the make-up pad and alcohol.

The pipe was ready for micro-meshing. The micro-meshing was done with 2 inch square micro-mesh pads 4000-12000. Between each pad I wiped the stummel with a make-up pad wetted with alcohol. The stem received a drop of Obsidian Oil rubbed in by finger and wiped with a paper towel between pads.

The little Danco was really looking good. Only a few things remained. The first of which was to polish the stem with Before and After Fin and the Extra Fine Polish. This was done by applying the polish with a finger and vigorous rubbing with a soft cotton cloth. I repeated the same process with the Extra Fine Polish. With the polishing finished I gave the stummel a coat of Before and After Restoration Balm and allowed it to do the magic that it does for 20 minutes. After 20 minutes, I wiped the remaining balm off with the inside of an athletic sock.

The pipe now needed a couple of coats of carnauba wax applied with the buffer.

I think this little Danco Lovat turned out very nicely. The only complaint I have about it is that the stem only fits perfectly one way rather than either way. That is hardly something worth complaining about. Okay, two complaints. The other is that stuck stinger. The pipe doesn’t have a bad draw to it but, I think it would be better without the constriction of the stinger. The grain of the briar looks very nice with the carnauba wax. The proportions of the pipe are very classic and classy. I would like to know more about the Danco brand if anyone knows more please feel free to reach out with comments. I do hope that something here has been useful to you with restorations of your own or that you were entertained. If you like this sort of thing please click the like and subscribe. Thank you very much for reading the ramblings of an old pipe lover.

Below are some photos of the finished Danco Lovat.