Photographed and written by

John M. Young

My affection toward Peterson pipes is hardly a secret, you could even say that I wear it on my sleeve. Though it is more literally on my hat.

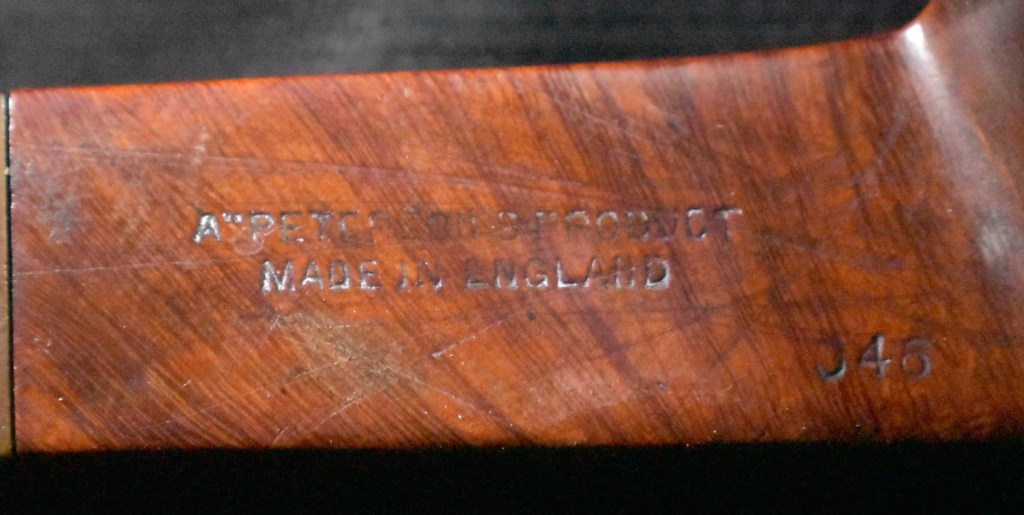

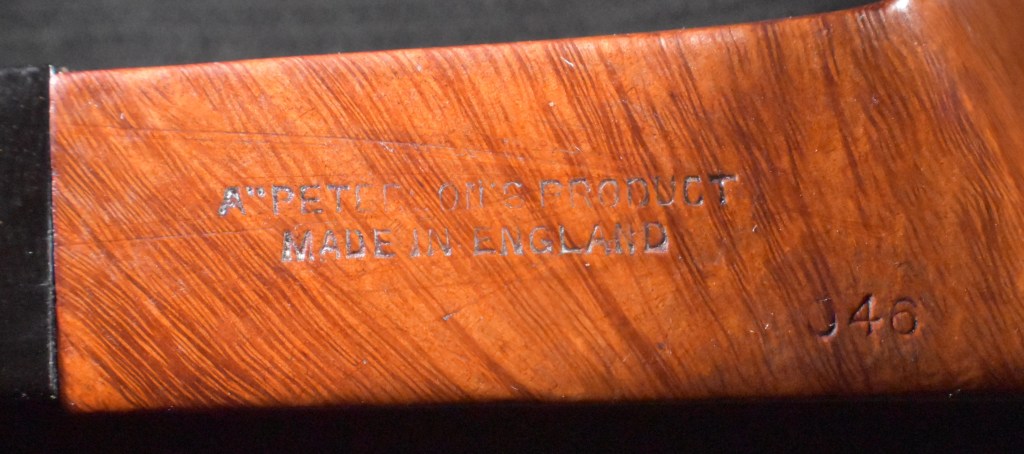

That said, I have restored dozens of Peterson pipes and I always enjoy doing it even when it is more of a pursuit of folly trying to salvage a very abused old implement rather than refreshing someone’s dear old frien.The subject of this blog is a Captain Pete I found last May on eBay. I probably paid more for it that I’d like to admit and certainly more than what I would have 3 years ago. Regardless, after a short trip from Englewood, Florida the not so lovely old pipe arrived. The stampings were mostly clear and read “CAPTAIN (0ver) PETERSON” on the top left shank. I’m not sure why the Peterson stamp folks like their quotation marks but they seem to. The stem was stamped with a worn and paint worn-off circled C. On the right shank the stamp read “A PETERSON PRODUCT” over MADE IN ENGLAND with an offset 046. The country of manufacture (COM) stamp is what intrigued me the most. More on that in the “Background”. The photos below show the pipe prior to any work.

This pipe appeared to look rough. The stem was severely oxidized, I feared saving the logo would be difficult at best. The bowl had been reamed but not very well. There was a layer of lava on the rim which looked like it had been removed and redeposited. I think what was thinking is that this l pipe appeared to have been smoked a lot but kind of kept up and cleaned on occasion.

Background

Back on December 21, 2023 I wrote a blog about a Captain Peterson apple. That blog is linked for those interested. In that blog I said the following about the Captain Peterson line:

“I highly recommend the book The Peterson Pipe, by authors Mark Irwin and Gary Malmberg as well as a reading of pipedia.com’s Peterson pages. According to Mark Irwin and Gary Malmberg, the Captain Pete:

“This line’s name was derived from the nickname of Charles Peterson, known affectionately as “Captain Peterson.” The first issue, c. 1940-62, was in a smooth finish produced for Rogers Imports with a white stamped P inside C, or a circled P on the mouthpiece. CAPTAIN over PETE on shank, and a MADE IN IRELAND in a circle. English made versions show CAPTAIN over PETE on shank or “CAPTAIN PETERSON” and A PETERSON PRODUCT over MADE IN ENGLAND or LONDON MADE over ENGLAND. The second issue (1998-), features an XL bowl with Sherlock Holmes shapes and compact stems, in rustic or combination of smooth and rustic, with a nickel band between two narrow brass bands.” (Irwin and Malmberg p.295)” (A Peterson Captain Pete Restoration – NebraskaPeteGeek)

This example of a Captain Peterson is described above and likely dates from 1940-62 and was made in London. These dates can be further narrowed down by reading p.149-150 in The Peterson Pipe, where the London production of pipes is discussed at length. Here, Irwin and Malmberg say, “Apparently, the London factory did not order a MADE IN ENGLAND die until after the war. Any Peterson stamped with an English COM must be no older than the later 1940s” (Irwin, p.150). This would mean that this pipe dates from 1945-1962 as 1962 was when Peterson shuttered the London factory.

The Restoration

After the before photos the pipe made its way to the workbench and a clean denim piece.

I began work with the stem due to thinking that the stem would require the greatest amount of time. The cleaning was done with bristle pipe cleaners and 95% ethyl alcohol. The stem was very fouled with tar and smoking residue.

The stem has some tooth chatter on the bit above the button on both the top and bottom surfaces as the two below photos show in all of their poorly focused glory.

The bits of the top and bottom surface were filed with a small slat file to remove most of the chatter.

The stem was suspended in Briarville’s Pipe Stem Oxidation Remover solution and allowed to soak for 24 hours. This solution is lovingly referred to as deox.

The next day the stem was removed and rubbed with a coarse shop rag. This removed a great deal of the oxidized vulcanite and can be seen on the rag in the photo below.

The airway of the stem was again cleaned with alcohol dipped bristle pipe cleaners.

I was pleased to see that the logo stamped on the stem remained intact after the time in deox.

To further reduce the amount of oxidized vulcanite, I rubbed the stem with Soft Scrub cleanser on make-up pads. The oxidized vulcanite can be seen darkly coloring the pads.

The stem was oiled with mineral oil to keep the vulcanite from further oxidation.

The tooth chatter that was not filed from the bite zone was filled with black cyanoacrylate (CA, super glue). This was spritzed with a CA drying accelerator. The hardened CA was then filed with a small flat file to smooth and reshape the stem.

The shank of the pipe was wrapped with masking tape to protect the briar and allow me a handle while sanding. The stem logo was also masked for its protection. The stem was sanded with a series of sanding sponges from grits 400-2000. Between each sponge the stem was rubbed with mineral oil and wiped with a paper towel to remove sanding debris.

The sanding continued through the 3500 grit sponge with oiling and wiping as above.

The stem was buffed using blue buffing compound on a low speed buffer with a flannel wheel dedicated to the blue compound.

The stem was wiped of any residual buffing compound and the logo area cleaned with alcohol on a cotton swab. I used a white acrylic model paint to repaint the imprint of the logo.

The white acrylic dried quickly and was hand buffed with a soft cotton cloth to remove the paint from the stem outside of the stamp.

The sequence of this restoration had me a bit out of sorts, but it was apparently time for the reaming. The tools were gathered.

The Pipnet #2 blade was the only one that fit and did most of the reaming. Both the Smokingpipes Low Country reamer and the General triangular scraper were used but just for clean-up.

Below the reamed tobacco chamber can be seen.

The chamber was sanded with 320 sandpaper wrapped around a wood dowel. I saw no signs of damage within the chamber. The lava on the rim was softened with saliva and allowed to soak for a couple minutes.

The rim was then scraped using the edge of a sharp pocket knife blade. There were some rough spots on the rim but they looked superficial and easily removed with a light topping.

The stummel was taken to the sink for a scrubbing with a nylon brush and undiluted Murphy Oil Soap. The soap was rinsed with warm water and the stummel dried with a cotton hand towel.

I packed the stummel with cotton and saturated it with 99% ethyl alcohol. This was allowed to sit overnight.

The next day the cotton was stained telling me the treatment had worked.

The cotton was removed and was far dirtier than I was used to. I could have sworn that I had cleaned the shank, yet I had no recollection of doing it. Remember when I said the sequence of this restoration had me out of sorts? It was apparently worse than I thought.

The airway was filthy and tar infested. The good news was that the tar was very soft due to the extended soaking in alcohol. The scraping with a dental scraper was very productive. The cotton swabs eventually started to lighten as more of the tars were removed.

I cannot say if this was a superior order to use than my normal sequence; reaming the chamber, then, clean the shank airway then alcohol/cotton treatment is needed for ghosting of severe dirtiness. In this case it worked well. The softening of the tar did make for easier cleaning.

There were several small dents, scratches or pits on the surface of the stummel. These revealed themselves more and I had started sanding. I had covered the stamps with masking tape for their protection. For the fills, I applied small amounts of thin CA using a long narrow applicator on the CA bottle. Immediately after application I used a dust sanding sponge to sand the fill area. The sanding sponge supplied the briar dust to join with the CA and for a fill. This method only works if the spots to be filled are very small and the sander has total disregard for their sanding sponges as some of the CA and briar dust will certainly get on the sponge making it have nonabrasive spots. I wonder if I will ever learn to use a piece of sandpaper like I did before I had sanding sponges. The next three photos show the fills.

The stummel was then sanded with the full series of sanding sponges from 400-3500 grit. The stummel was wiped with a make-up pad wetted with alcohol between each sponge

I removed the masking tape and cleaned any adhesive left behind by the tape. I then worked the stummel with micro-mesh pads 4000-12000. Again I wiped the stummel between pads with alcohol on a make-up pad.

The stummel was coated with Before and After Restoration Balm and allowed to sit while I went out in search of a couple of evening Largemouth bass. This is also called my stroll with a pole and of course a pipe.

About an hour and a half later I returned and wiped the remaining Restoration Balm from the stummel with an inside out athletic sock. There is the photobombing fishing pipe lurking in the background. If you are curious it is a Peterson 127.

The pipe was taken to the buffer where a couple of coats of carnauba wax were applied.

I carefully dragged a knife blade around the beading to remove accumulated wax from the grooves. The final step was another hand buff with the microfiber polishing cloth then off to the final photo shoot.

This beautiful English made Captain Peterson 046 bulldog is a great example of post World War Two English workmanship. The walnut stain of the original pipe was maintained and was finished with careful sanding and just carnauba wax. The stem was deoxidized, sanded and polished to a gorgeous glossy luster. Though lacking any stunning briar grain the wood is solid and the few dents from wear were filled with minimal disruption to the original. The dimensions of the Peterson Captain Peterson Made in England 046 bulldog are:

Length: 5.71 in./ 145.03 mm.

Weight: 1.62 oz./ 45.93 g.

Bowl Height: 1.96 in./ 49.78 mm.

Chamber Depth: 1.65 in./ 41.91 mm.

Chamber Diameter: 0.73 in./ 18.54 mm.

Outside Diameter: 1.64 in./ 62.89 mm.

I do hope that you have found something here useful to your own pipe care, maintenance or restorations. If you like this sort of thing, please click the like and subscribe buttons. Thank you for reading the ramblings of an old pipe lover.

Below are some photos of the finished Peterson Captain Peterson Made in England 046 bulldog.

I did not want to affect the stamps here, so the existing scratches were not sanded away like I would have preferred to do.